World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3603A316A - Heat Sink Assembly Module is available in stock which ships the same day.

IC3603A316A - Heat Sink Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3603A316A - Heat Sink Assembly Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3603A316A

Manufacturer: General Electric

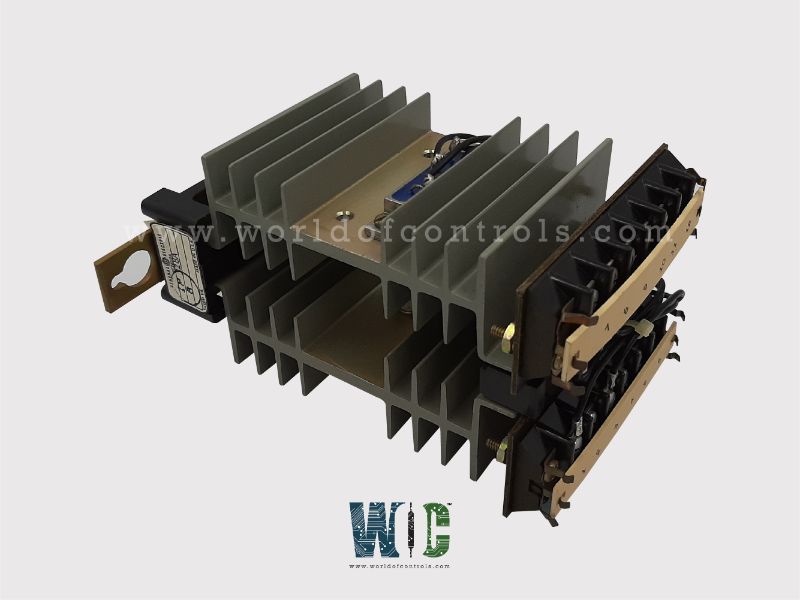

Product Type: Heat Sink Assembly Module

Series: Mark I & II

Input Voltage: 100-240V AC, 50/60Hz

Output Current: 0.15 A AMP

Output Voltage Range: 0-50V DC

Operating Temperature: 0°C to 40°C

Resolution: 10mV/10mA

Availability: In Stock

Weight: 2.5 kg

Dimensions: 6.00 x 6.00 x 5.00

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3603A316A is a Heat Sink Assembly Module manufactured and designed by General Electric and is part of the Mark II Series used in Static Starter Control systems. A heat sink assembly module is a critical component used in electronic devices to dissipate heat generated by various components such as processors, power transistors, and other heat-generating elements. Effective heat dissipation is essential to maintain optimal performance and prevent overheating, which can lead to component failure or reduced lifespan.

FUNCTIONS OF HEAT SINK ASSEMBLY MODULES:

WOC has the largest stock of replacement parts for GE Speedtronic Gas turbine control systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a heat sink assembly module, and why is it important in gas turbine control systems?

A heat sink assembly module is a device that dissipates heat from electronic components to maintain optimal operating temperatures. In gas turbine control systems, it is crucial because it prevents overheating, ensures reliable operation, and extends the lifespan of electronic components such as power electronics and control processors.

What materials are commonly used for heat sink assembly modules in gas turbine control systems?

Heat sinks are typically made from materials with high thermal conductivity, such as aluminum or copper. These materials efficiently transfer heat away from critical components.

How does the design of a heat sink affect its performance?

The design, including the number and arrangement of fins or pins, significantly impacts a heat sink's ability to dissipate heat. More surface area and efficient fin geometry enhance heat dissipation, improving thermal management.