World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3600STKP1D - Peaking Operation Drive Board is available in stock which ships the same day.

IC3600STKP1D - Peaking Operation Drive Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600STKP1D - Peaking Operation Drive Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

Part Number: IC3600STKP1D

Manufacturer: General Electric

Series: Mark I & II

Type: Drive Board

Coil Voltage: 251-300 V

Current Rating: 41-50 A

Availability: In Stock

Product of Origin: U.S.A

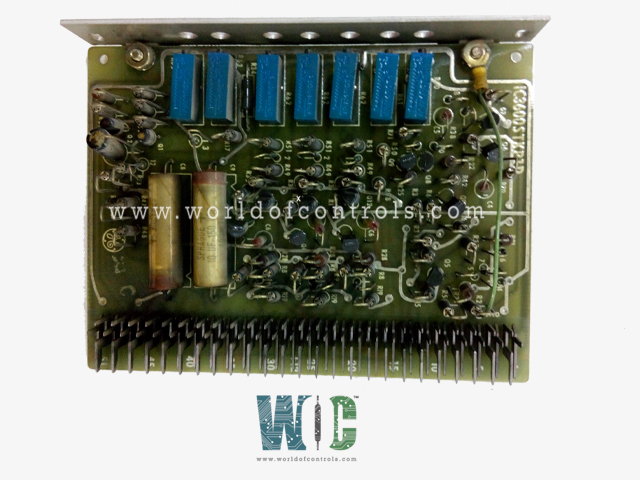

IC3600STKP1D is a Peaking Operation Drive Board manufactured and designed by General Electric as part of the Mark II Series used in Gas Turbine Control Systems. Mark, I & II have been used to manage and automate turbine processes since 1969 and 1973, respectively. These were the first series introduced in the GE Mark line. The is a printed circuit board (PCB) with a metal plate attached to its left side. A series of potentiometers are arranged in a line next to this plate. Every potentiometer, also known as a variable resistor, has a knob that allows the resistance of each device to be adjusted if necessary. It is linked to the rest of the turbine system via a series of metal prongs located on the far right side of the PCB.

FEATURES:

WOC has the largest stock of GE Fanuc Mark II Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS

What is GE Mark II IC3600STKP1D?

It is a Peaking Operation Drive Board developed by General Electric and used in gas turbine control systems.

Are the Products Genuine OEM Units?

These items have been certified by WOC Quality Control to be genuine OEM Units obtained through OEM or independent third-party channels.

How are boards packaged for shipment from WOC?

Parts are placed in antistatic packets and securely packed in ESD boxes cushioned with ESD Foam designed to safeguard electrical components.