World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

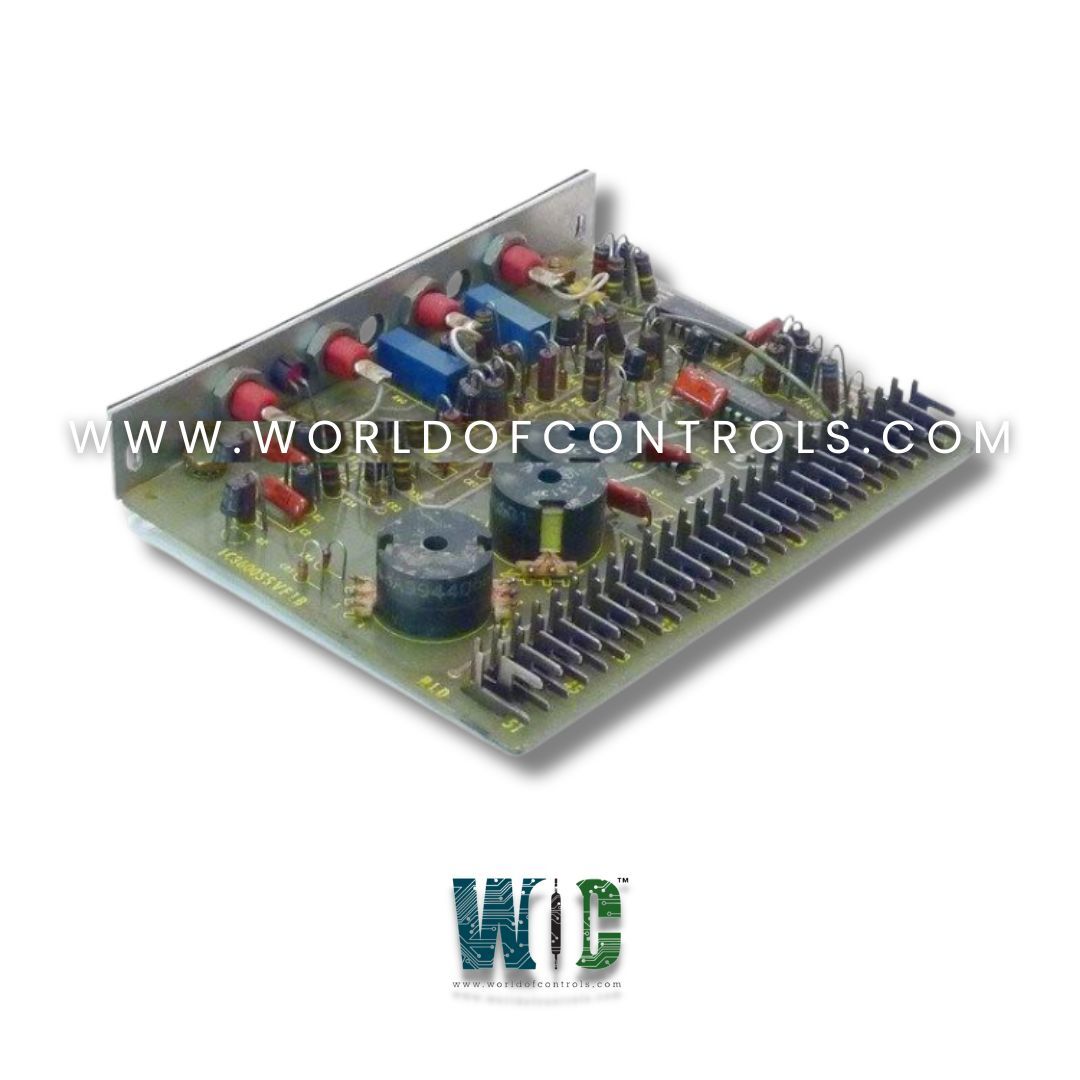

IC3600SSVF1C - Servo Valve Feedback Card is available in stock which ships the same day.

IC3600SSVF1C - Servo Valve Feedback Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SSVF1C - Servo Valve Feedback Card, contact us and we will get back to you within 24 hours.

Part No.: IC3600SSVF1C

Manufacturer: General Electric

Product Type: Servo Valve Feedback Card

Availability: In Stock

Series: VersaMax

IC3600SSVF1C is a Servo Valve Feedback Card developed by GE. It is a part of GE Mark I and II series. Designed to receive and process feedback signals from servo valves that control actuator movements. These feedback signals are compared to control signals issued by the Speedtronic system to ensure accurate and stable positioning. Any deviation between the desired and actual positions is corrected in real-time, enabling precise control of turbine performance and maintaining optimal efficiency and safety.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

What is IC3600SSVF1C?

It is a Servo Valve Feedback Card developed by GE.

Will the turbine keep running if there's a failure in one protection path?

Yes, in many cases, the turbine will continue to run if a single failure occurs, provided the other protection paths are functional. However, the failure will be annunciated to the operator, prompting inspection and repair.

What is meant by trip routes?

Trip routes are electrical or mechanical pathways through which a shutdown command can be sent. Having multiple trip routes ensures that if one fails, others can still initiate a turbine shutdown.