SPECIFICATIONS

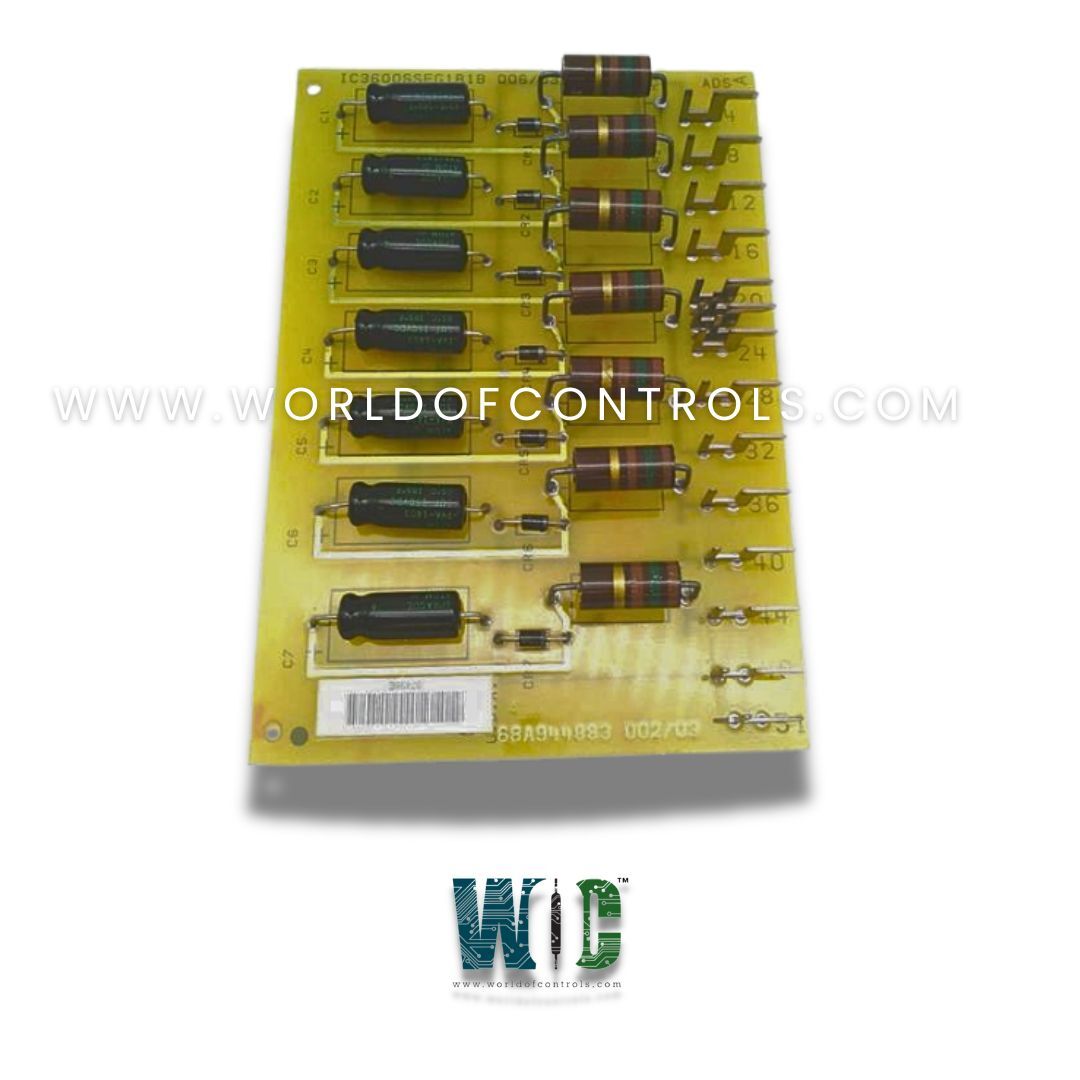

Part No.: IC3600SSFG1B

Manufacturer: General Electric

Product Type: Interface Board

Availability: In Stock

Series: VersaMax

Functional Description

IC3600SSFG1B is an Interface Board developed by GE. It is a part of GE Mark I and II series. It performs signal processing and communication within the turbine control architecture. It is designed to connect different modules and components within the control system, ensuring smooth data transmission and functional coordination between sensors, relays, and control logic units.

System Features

- The control system offers a range of advanced features designed to optimize the operation of gas turbines and support operators in ensuring safe and efficient performance. These features are built into the system to enhance both the turbine's functionality and the operator's control over critical parameters, enabling more precise management during different operating conditions.

- One of the key features of the system is the Minimum VCE System (Minimum Variable Compressor Exit Pressure). This system plays a crucial role during situations where fuel flow needs to be reduced, such as in cut-back operations. During these times, it ensures that the gas turbine maintains a minimum fuel flow to the unit, helping to avoid flame-out � a critical issue where the combustion process in the turbine is interrupted, potentially leading to system shutdown or damage. The Minimum VCE System continuously monitors fuel levels and adjusts them to ensure that combustion remains stable, even as power demand decreases.

- Another valuable feature of the control is the Manual VCE control. This feature is particularly useful during initial startup procedures or in cases where the turbine experiences operational issues. The Manual VCE allows an operator or technician to take direct control over the Variable Compressor Exit Pressure (VCE), which directly affects fuel flow to the turbine. By having this control at hand, the operator can fine-tune fuel settings to ensure smooth startup or make necessary adjustments during troubleshooting. This gives the operator full flexibility to manage the start-up or loading process of the turbine according to specific needs, especially when conditions deviate from normal operating ranges.

- Importantly, the Manual VCE control operates through a minimum value gate, which means that while the operator has manual control over fuel, the system still retains its automatic protection capabilities. For example, other parameters like turbine speed and exhaust temperature are continuously monitored, and if they reach critical thresholds, the system can automatically intervene to reduce fuel flow and prevent turbine damage. This layer of safety logic ensures that, even when manual control is engaged, the turbine remains protected from excessive operating conditions.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IC3600SSFG1B?

It is an Interface Board developed by GE.

How does the Minimum VCE System work to prevent flame-out?

The system continuously monitors fuel flow to the turbine. When fuel cut-back is necessary, the Minimum VCE System adjusts the fuel flow to ensure that the turbine retains enough fuel to maintain combustion, thus avoiding a flame-out scenario, which could otherwise lead to a shutdown or damage.

What is the Manual VCE control, and when is it used?

The Manual VCE control allows the operator or technician to take manual control over the turbine's Variable Compressor Exit Pressure (VCE), which directly affects the fuel flow. It is primarily used during initial startup or for troubleshooting, providing the operator with the flexibility to manage the turbine's loading and start-up process manually.