World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

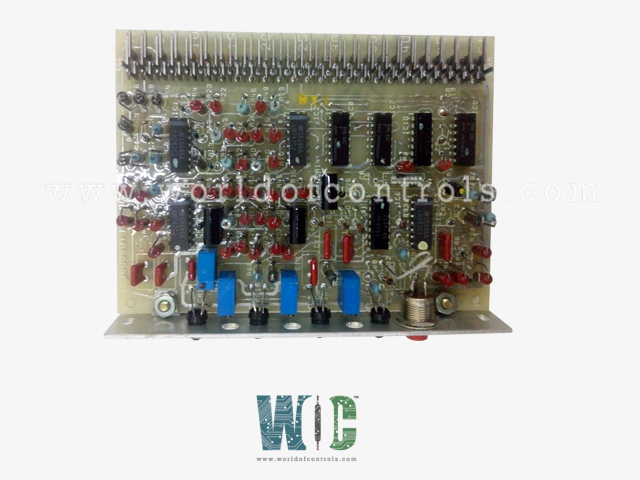

IC3600SOTK1 - Overtemperature Protection Card is available in stock which ships the same day.

IC3600SOTK1 - Overtemperature Protection Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SOTK1 - Overtemperature Protection Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3600SOTK1

Manufacturer: General Electric

Product Type: Overtemperature Protection Card

Series: Mark II

Operating temperature: -30 to 55 ºC

Power Supply Voltage: 24 V dc

Board Size: 2.8 cm high x 8.6 cm

Weight: 0.45 kg

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600SOTK1 is an Overtemperature Protection Card manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. An Overtemperature Protection Card (OTP Card) is an electronic device used in various industrial and electrical systems, particularly in turbine control systems, to monitor and manage temperature levels. Its primary function is to protect equipment from damage caused by excessive temperatures by triggering alarms or initiating protective actions such as shutdowns. Here are the key components and functions of an OTP Card:

KEY COMPONENTS:

FUNCTIONS:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

Where are Overtemperature Protection Cards commonly used?

OTP Cards are commonly used in turbine control systems, electrical transformers, motors, industrial manufacturing processes, and other applications where temperature monitoring and control are critical for safety and operational efficiency.

How does an Overtemperature Protection Card work?

The OTP card continuously monitors temperatures through connected sensors. If the temperature exceeds preset thresholds, the card triggers alarms and, in severe cases, initiates protective actions such as shutting down the equipment.

What happens when an OTP card detects an overtemperature condition?

When an overtemperature condition is detected, the OTP card activates alarms to alert operators. If the temperature continues to rise beyond safe limits, the card may initiate an automatic shutdown to prevent equipment damage.