World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3600SHPB1E - Single Shaft Auxiliary Card is available in stock which ships the same day.

IC3600SHPB1E - Single Shaft Auxiliary Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SHPB1E - Single Shaft Auxiliary Card, contact us and we will get back to you within 24 hours.

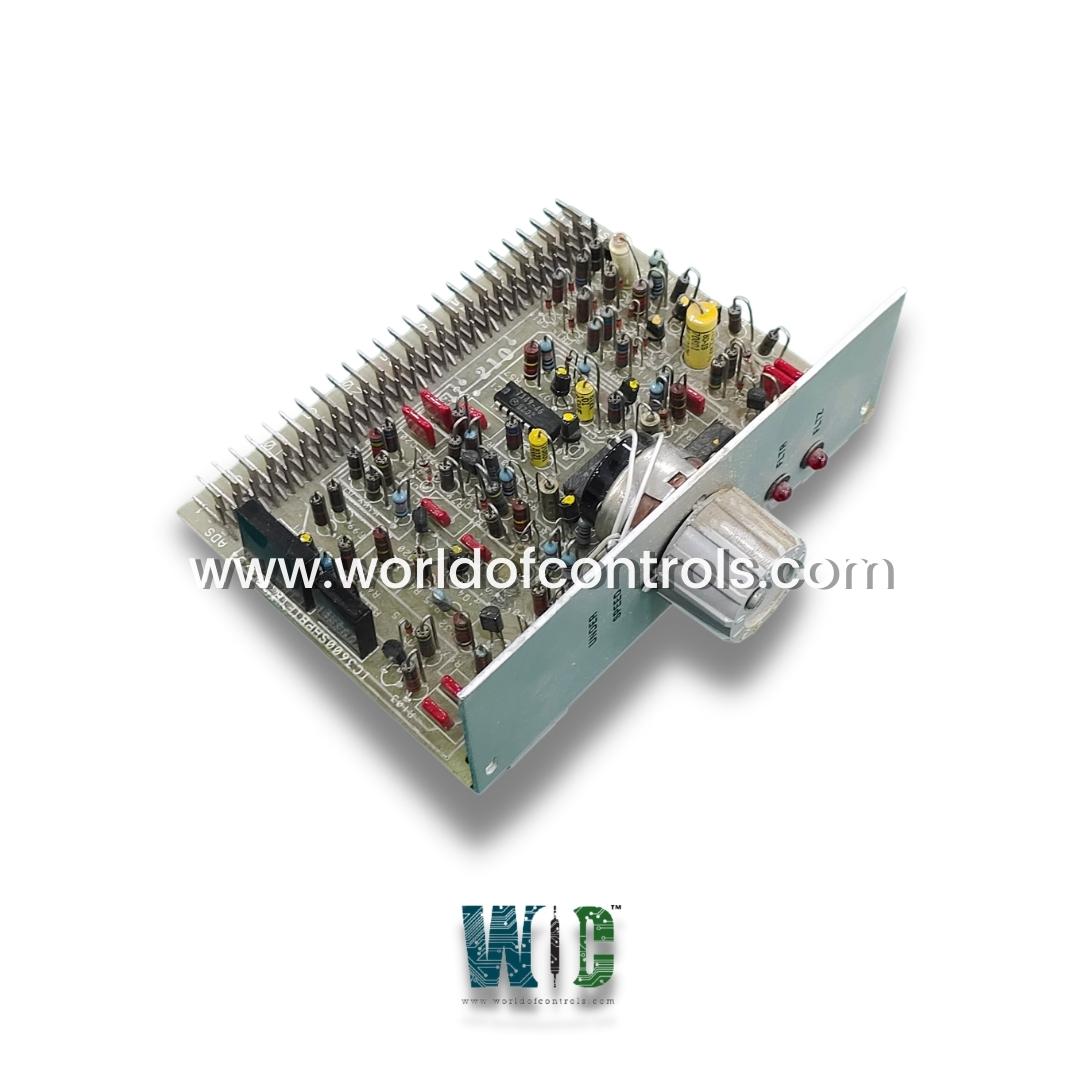

Part No.: IC3600SHPB1E

Manufacturer: General Electric

Product Type: Single Shaft Auxiliary Card

Availability: In Stock

Series: VersaMax

IC3600SHPB1E is a Single Shaft Auxiliary Card developed by GE. It is a part of GE Mark I and II series. It is responsible for managing auxiliary functions that support the main operations of power generation equipment, such as generators and turbines. These functions may include monitoring system parameters, controlling auxiliary devices, and providing diagnostic information to the control system. The card ensures the smooth and efficient operation of the turbine and generator units by managing these secondary systems.

The calibration of the control panel is an essential step in ensuring the accurate functioning of turbine control systems. It involves fine-tuning specific components and systems within the control card to ensure that the readings and outputs are within the correct operational parameters.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

What is IC3600SHPB1E?

It is a Single Shaft Auxiliary Card developed by GE.

What is the purpose of calibrating the turbine control panel?

Calibration ensures that the turbine control system is providing accurate readings and functioning as intended. Adjusting specific components ensures the system operates within the correct parameters, optimizing the turbine's performance and safety.

What are the key components that need calibration on the turbine control panel?

The key components that need calibration include the temperature control card, pressure transducers, position sensors, and other critical devices that monitor the turbine's performance. These components ensure that the turbine operates efficiently and within safe limits.