World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3600AOAM - Dual Operating Amplifier Board is available in stock which ships the same day.

IC3600AOAM - Dual Operating Amplifier Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600AOAM - Dual Operating Amplifier Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

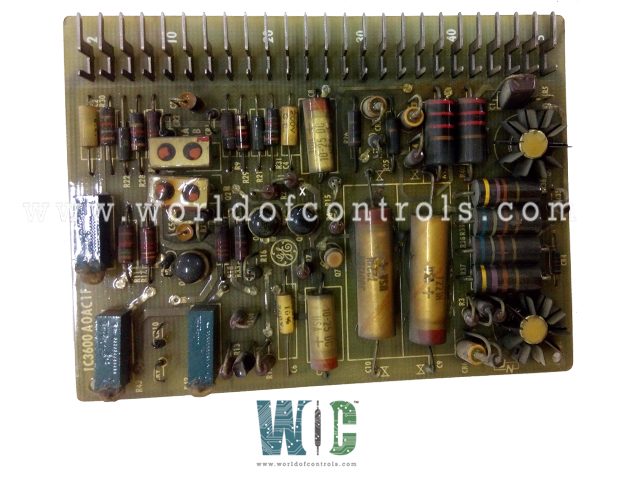

Part No: IC3600AOAM

Manufacturer: General Electric

Product Type: Dual Operating Amplifier Board

Series: Mark II

Input Signal Voltage: ±10 V

Output Signal Voltage: ±10 V

Amplifier Gain: 1× to 10× adjustable

Offset Voltage: 1 mV

Input Impedance: 100 k Ohms

Power Supply: ±15 V DC nominal

Operating Temperature: 0°C to 70°C

Weight: 2.90 lbs

Dimensions: 19.00 x 12.50 x 3.50

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600AOAM is a Dual Operating Amplifier Board manufactured and designed by General Electric is part of the Mark I & II Series used in gas turbine control systems. It provides precise analog signal amplification and conditioning, enabling accurate processing of input signals from various sensors, including speed, temperature, and pressure transducers. The board integrates two high-gain operational amplifiers with matched characteristics to ensure minimal offset, low drift, and high linearity, supporting stable turbine control operations. It interfaces directly with the analog input/output modules of the control system, contributing to reliable feedback and control loops for turbine operation, protection, and monitoring. The board is suitable for both replacement and system upgrade applications and is available in unused or refurbished condition.

OPERATION:

It receives low-level analog input signals from turbine sensors, amplifies them with high precision, and outputs conditioned signals to the control logic for processing. The dual op-amps work in tandem to maintain signal integrity, minimize noise, and ensure accurate representation of turbine parameters such as speed, temperature, and pressure. The board supports closed-loop control by providing stable feedback to the turbine control system, enabling precise adjustments to actuator commands and ensuring safe and efficient turbine operation. The board ensures signal integrity, stability, and minimal noise, enabling safe and efficient turbine operation. Key operational aspects include:

COMPATIBILITY:

It interfaces directly with the system’s analog input/output modules, enabling accurate amplification and conditioning of signals from critical turbine sensors. The board is compatible with a range of transducers, including speed sensors, thermocouples, RTDs (resistance temperature detectors), and pressure transducers, providing reliable signal processing for monitoring and control loops. Both unused and refurbished units are fully suitable for replacement, retrofitting, or system upgrades without requiring modifications to existing hardware or control logic.

WOC offers the largest stock of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems, including unused, rebuilt, and professionally repaired boards, all backed by a reliable warranty. Our team of technical experts is available 24/7 to support all automation needs, from diagnosing and repairing faulty boards to supplying fully tested replacements. Covering a wide range of modules such as operational amplifier boards, relay cards, exciter modules, and analog/digital interface boards, WOC ensures fast, dependable service to minimize turbine downtime and maintain peak system performance. With comprehensive technical guidance and installation support, we help clients optimize turbine operation, extend system life, and achieve reliable control system functionality. For pricing, availability, or technical assistance, contact our team via phone or email.

What is a dual operational amplifier board?

A dual operational amplifier board contains two precision op-amps on a single PCB. It is used to amplify, condition, and stabilize low-level analog signals for accurate processing in industrial control systems. The board ensures minimal offset, low drift, and high linearity, supporting reliable feedback in closed-loop control systems.

What are the primary applications of this board?

The board is primarily used in gas turbine control systems to process analog signals from speed, temperature, and pressure sensors. It provides accurate input to control logic modules, enabling precise actuator control and monitoring. It also supports closed-loop control for stable and safe turbine operation.

How does the board maintain signal accuracy?

The dual op-amps are designed for high gain, low offset, and minimal thermal drift. High linearity ensures accurate signal representation over the full input range. These features preserve signal integrity for reliable turbine control and monitoring.