World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

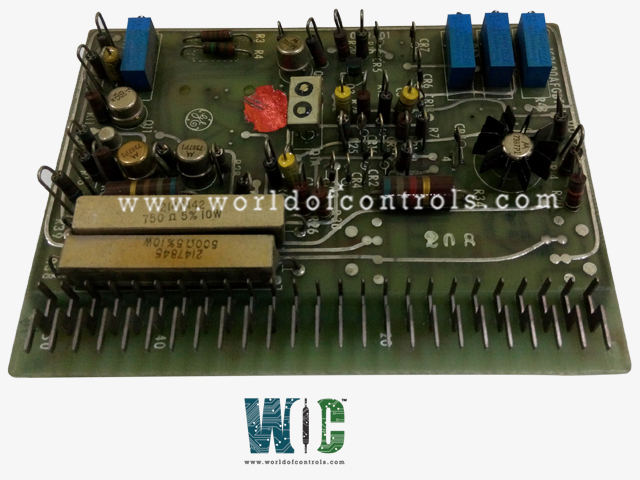

IC3600AFGB1C1B - Timed Accel Board is available in stock which ships the same day.

IC3600AFGB1C1B - Timed Accel Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600AFGB1C1B - Timed Accel Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IC3600AFGB1C1B

Manufacturer: General Electric

Series: Mark I & II

Function: Acceleration/Deceleration Profile Generation

Module Name: Timed Accel Board

Number of Channels: 3

Input Voltage Range: 0�10 VDC

Input Signal Type: �10 VDC

Output Signals: Analog Voltage

Power Consumption: 2.5 W

Power Supply: +12 VDC

Mounting: Rack-mounted

Operating Temperature: -20�C to +70�C

Number of Red LEDs: 3

Dimensions: 15.2 cm � 17.8 cm

Availability: In Stock

Product of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600AFGB1C1B is a Timed Accel Board manufactured and designed by General Electric for the Mark I & II Series used in gas turbine control systems. It receives start, stop, or speed commands from the main control system and converts them into time-dependent acceleration or deceleration signals, ensuring smooth ramp-up and ramp-down of turbine speed while minimizing mechanical stress. The board performs signal conditioning on incoming commands, filtering noise, and generating output waveforms that correspond accurately to the desired ramp rates. It integrates closely with other IC3600 control modules, coordinating with load sharing, speed reference, and trip logic to maintain turbine stability during transient operations. Additionally, the Timed Accel Board enforces safe operating limits by restricting acceleration and deceleration rates and providing fail-safe outputs to prevent unsafe turbine starts in the event of internal faults.

INPUT SIGNALS:

The Timed Accel Board receives a variety of input signals from the turbine control system and associated sensors to generate precise acceleration and deceleration profiles. Primary inputs include start/stop commands, speed reference signals, and load demand signals, typically in the form of analog voltages or currents. These signals are processed to determine the desired rate of turbine speed change and to coordinate ramping sequences with other control modules. The board also accepts feedback signals from the turbine, such as actual speed or position indicators, allowing closed-loop control to ensure that acceleration and deceleration occur smoothly and within safe mechanical limits.

SIGNAL PROCESSING & CONDITIONING:

The Timed Accel Board performs precise signal processing to ensure accurate acceleration and deceleration control. Incoming analog or digital signals, including start/stop commands, speed references, and turbine feedback, are filtered to remove noise and transient disturbances that could affect system stability. The board scales, offsets, and shapes these signals to generate a smooth, time-dependent control waveform compatible with the turbine actuators. Signal conditioning also includes protection against overvoltage, signal spikes, and erroneous inputs, ensuring that only valid and stable commands influence the acceleration profile. This processing is critical for maintaining coordinated operation with other IC3600 modules and for preventing abrupt or unsafe turbine speed changes.

SYSTEM INTEGRATION:

The Timed Accel Board is fully integrated into the IC3600 turbine control system, working in coordination with other modules such as speed reference boards, load sharing controllers, and trip logic units. It communicates directly with the main control processor to receive start/stop commands, speed references, and feedback signals, and its outputs are used to drive actuators or servos that modulate turbine speed. Integration ensures that acceleration and deceleration profiles are synchronized with overall turbine operation, including load changes, system ramps, and emergency shutdown sequences. The board�s interface follows standard IC3600 electrical and communication protocols, allowing seamless interaction with both upstream controllers and downstream actuator systems while maintaining system stability and operational safety.

We maintain the most comprehensive inventory of replacement parts for GE Speedtronic Turbine Control Systems, including both unused, warranty-backed boards and expertly refurbished modules designed to meet rigorous operational standards. Beyond providing replacement components, we offer specialized repair and restoration services for damaged or malfunctioning boards, ensuring reliable performance and extending the service life of critical turbine control equipment. Our team of highly skilled engineers and technicians delivers 24/7 support, assisting with OEM requirements, technical troubleshooting, system upgrades, and automation solutions to minimize downtime and optimize overall system efficiency. Whether you require detailed component specifications, urgent repair services, or guidance on system integration, we are ready to provide prompt, dependable assistance via phone or email, helping you maintain continuous, high-performance operation.

What is IC3600AFGB1C1B?

IC3600AFGB1C1B is a Function Generator Printed Circuit Board used in GE IC3600 Speedtronic Mark I/II turbine control systems. It generates precise timing and waveform signals required for turbine control, including analog and digital outputs for synchronous operation. The board ensures proper signal coordination with other modules, maintaining system stability under transient conditions.

What is the function of the Timed Accel Board?

The Timed Accel Board generates time-dependent acceleration and deceleration profiles for turbines. It converts start/stop or speed reference commands into controlled ramp signals for actuators or servos. This prevents abrupt mechanical loads, improves turbine longevity, and ensures a smooth transient response during start-up and shutdown.

What types of input signals are accepted by the board?

The board accepts start/stop commands, speed reference voltages, load demand signals, and turbine speed feedback. Inputs are generally �10 VDC analog or up to 20 mA current. These inputs are conditioned to remove noise, scaled appropriately, and processed to ensure precise control waveform generation.

How is signal conditioning performed on the Timed Accel Board?

The board performs filtering, scaling, offsetting, and waveform shaping to produce smooth ramp outputs. Noise suppression and transient elimination are applied to avoid actuator oscillations. This ensures outputs match the desired acceleration/deceleration profiles with minimal deviation under varying load conditions.