SPECIFICATIONS

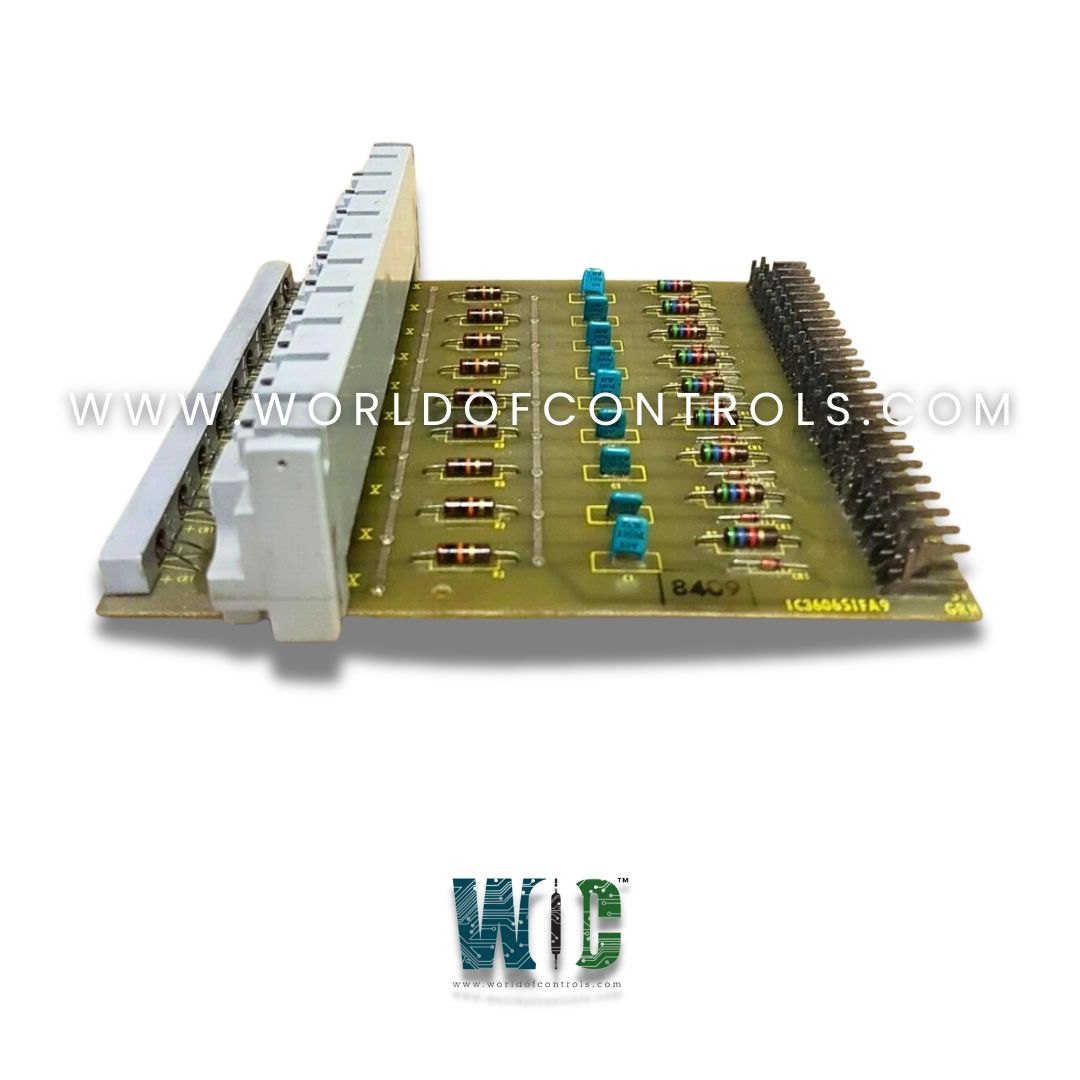

Part No: IC3606SIFA9C1B

Manufacturer: General Electric

Function: Non-Isolated Input Filter Board

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

IC3606SIFA9C1B is a Non-Isolated Input Filter Board developed by GE. It is a part of Mark I and II control system. It filters incoming input signals to remove unwanted noise and transient disturbances before they are processed by the control system. Since it is a non-isolated board, it shares a common electrical ground with the control system, which allows for a more compact design and faster signal processing but requires careful grounding practices to avoid signal interference.

Features

- This board does not include galvanic isolation, which allows signals to pass directly into the control system without transformation. While this allows for quicker signal response and simplified circuitry, it requires that the signal source shares a common reference potential with the system.

- Responsible for filtering noise and stabilizing signals coming from external sources such as sensors, switches, or transmitters. Clean input signals are critical for ensuring the control logic receives accurate real-world data for decision-making.

- The board can handle various types of input signals, including low-level analog voltages or discrete digital signals. It prepares these signals for further amplification, conversion, or logic-level processing.

System Vibration Transducers

- Vibration transducers are essential components used to monitor the health and performance of rotating machinery such as turbines. These sensors are designed to be velocity-sensitive, meaning the output voltage they produce is directly proportional to the vibration velocity of the machine. Monitoring vibration levels is a key aspect of preventive maintenance, helping identify early signs of mechanical wear or failure.

- The typical design of a vibration transducer involves a permanent magnet suspended on low-compliance springs within the sensor housing. A coil is mounted to the frame of the sensor, which is securely fastened to the turbine casing. When the turbine vibrates, the frame (and thus the coil) moves, while the suspended magnet remains relatively stationary. This relative motion between the coil and magnet induces a voltage through electromagnetic induction, which is then processed by the system’s electronics.

- One of the advantages of this design is its durability and simplicity. With few moving parts and no direct mechanical contact between the magnet and coil, the sensor operates reliably over long periods. The signal it produces is a faithful representation of the vibration velocity, allowing for accurate monitoring of mid- to low-frequency vibrations typical in industrial environments.

- To ensure the transducer is functioning correctly, a small current is passed through the coil, producing a constant DC output related to the coil’s resistance. This serves as a self-diagnostic feature—if the resistance deviates from expected values, it may indicate a failure, such as an open or short circuit, and prompt maintenance teams to take corrective action.

- These vibration transducers are commonly used in gas and steam turbines, compressors, motors, and other critical rotating equipment. They help detect issues such as imbalance, misalignment, bearing faults, and looseness—all of which can lead to costly downtime if not addressed promptly.

- By providing reliable, velocity-based vibration measurements and integrating easily into both modern and legacy systems like GE’s Mark I and II control platforms, these transducers contribute significantly to equipment safety, efficiency, and longevity.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IC3606SIFA9C1B?

It is a Non-Isolated Input Filter Board developed by GE.

Why is signal filtering important?

Filtering ensures that only clean, stable input signals reach the control system. This helps prevent false readings or erratic behavior caused by electrical noise, transients, or interference from external devices.

What types of input signals can this board handle?

The board is capable of processing low-level analog signals as well as discrete digital signals coming from devices such as switches, sensors, or transmitters.