World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3600VBCU1B - Variable Binary Counter Card is available in stock which ships the same day.

IC3600VBCU1B - Variable Binary Counter Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600VBCU1B - Variable Binary Counter Card, contact us and we will get back to you within 24 hours.

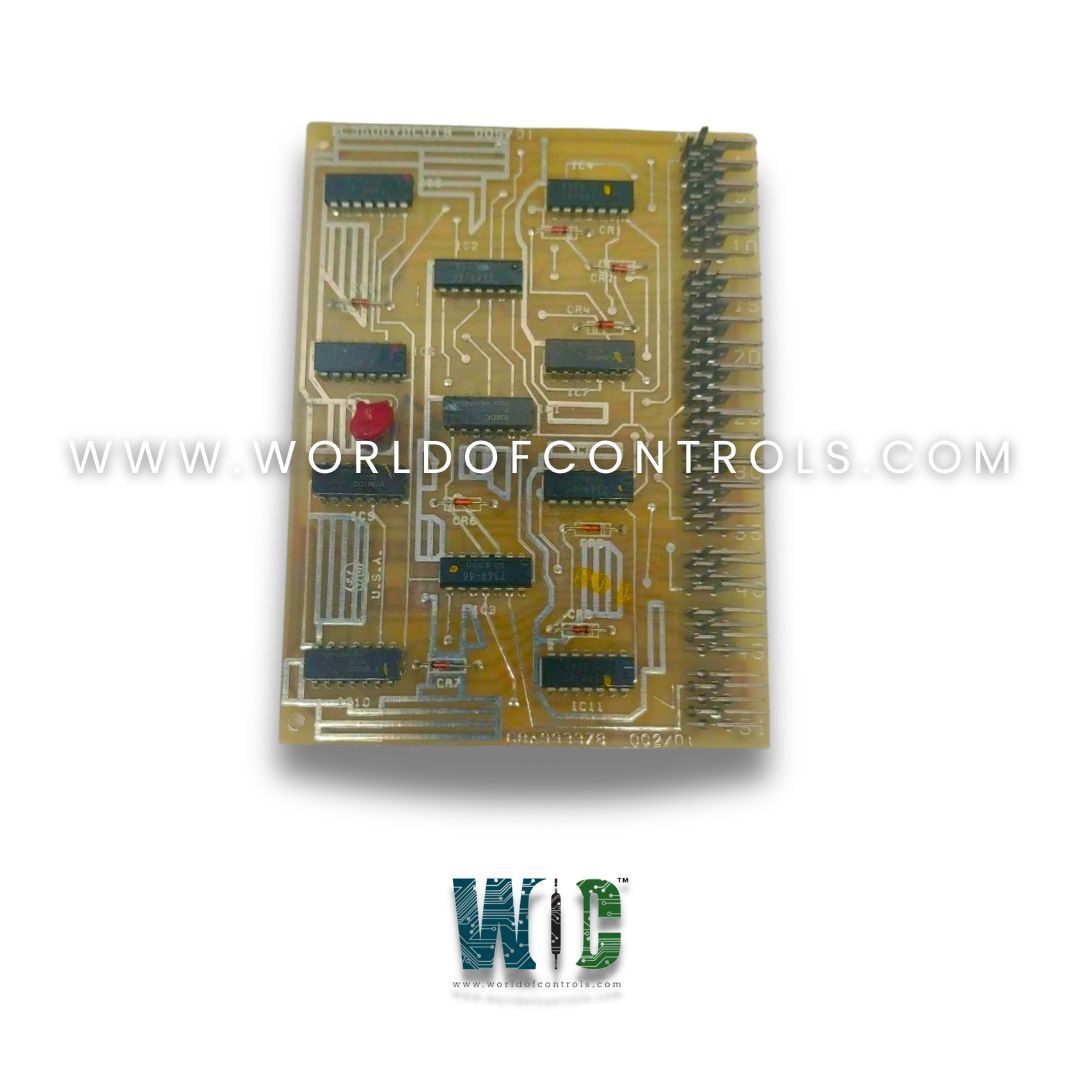

Part Number: IC3600VBCU1B

Manufacturer: GE Fanuc

Country of Manufacture: United States(USA)

Availability: In Stock

Product Type: Variable Binary Counter Card

IC3600VBCU1B is a Variable Binary Counter Card manufactured by GE Fanuc. It is a part of Mark I and II control systems. The card is responsible for counting binary signals and processing them in real-time. As a Variable Binary Counter (VBC), it enables the counting of discrete events or pulses, which is crucial in systems that require precise control and monitoring of operational states. This functionality is essential for various processes, such as counting rotations of turbine shafts, monitoring signal states from sensors, or tracking other industrial parameters that need to be monitored over time.

WOC has the largest stock of Speedtronic Mark II Spare Parts and we can repair your faulty spares with a warranty. Our team of experts is available to support your urgent needs related to critical spares, contact us.

What is GE Fanuc IC3600VBCU1B?

It is a Variable Binary Counter Card used in gas turbine control systems.

How does the card contribute to system safety?

The card enhances system safety by monitoring critical binary signals that reflect important operational parameters. If an abnormality is detected, the control system can take appropriate action to prevent potential damage to equipment, reducing downtime and ensuring safe operation.

How does the Variable Binary Counter function?

The Variable Binary Counter on the card processes discrete binary input signals (representing events or pulses) and provides accurate counts in real-time. These counts can be used to monitor various system parameters, which are essential for controlling turbine speed, flow rates, and other operational factors.