SPECIFICATIONS

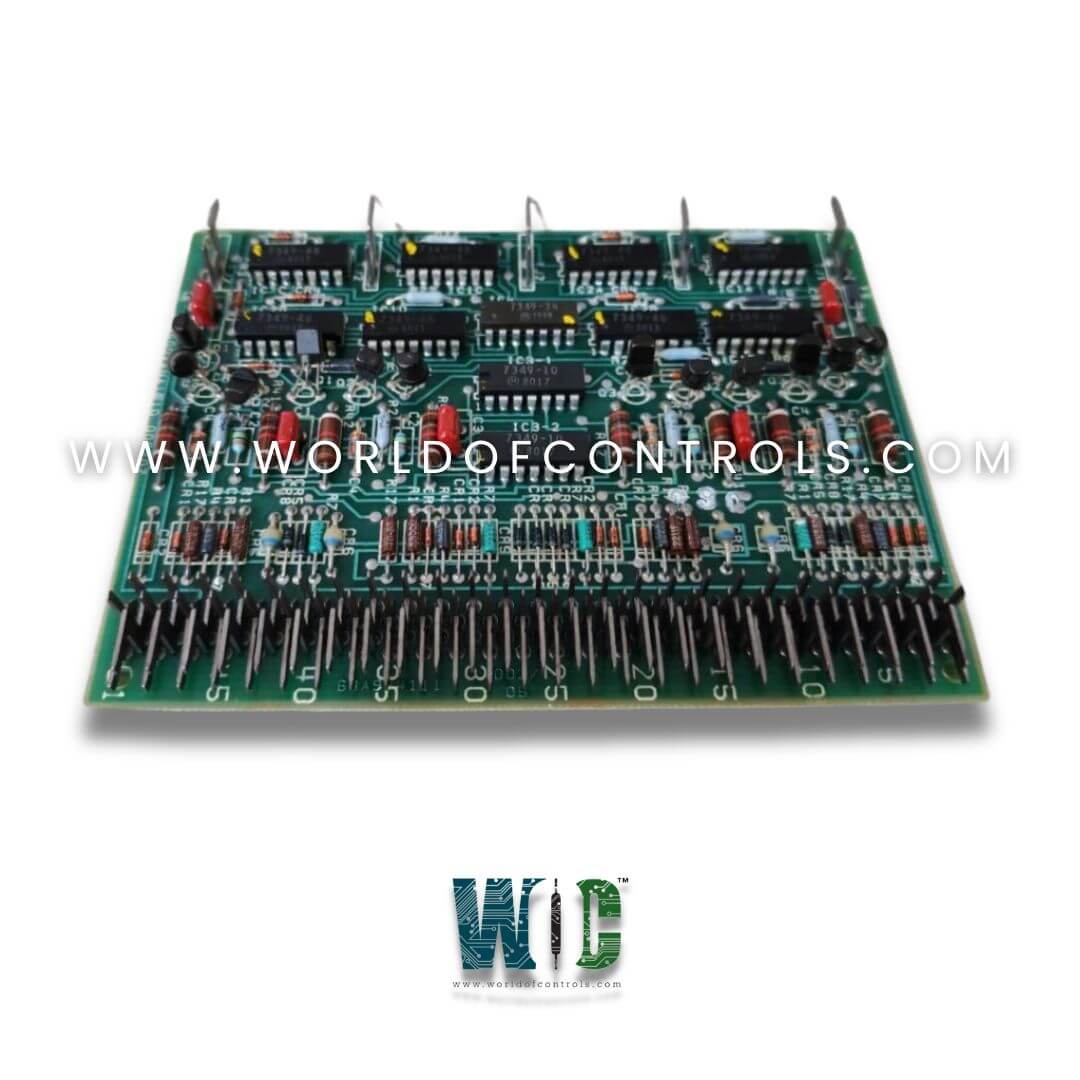

Part Number: IC3600VANA1C

Manufacturer: GE Fanuc

Country of Manufacture: United States(USA)

Availability: In Stock

Product Type: Annunciator Board

Functional Description

IC3600VANA1C is an Annunciator Board manufactured by GE Fanuc. It is a part of Mark I and II control systems. The primary function of the board is to serve as a fault indication and status reporting interface. It collects and displays operational information from various sensors and subsystems within the turbine control system. By providing visual and/or audible alerts regarding abnormal conditions, this annunciator board allows operators to respond quickly to faults, minimizing downtime and preventing equipment damage.

Protective Systems in Gas Turbine Control

- The protective system in a gas turbine is a vital component designed to monitor the unit's operating conditions and ensure its safe shutdown in the event of abnormal behavior. It functions as a safeguard against potential equipment damage and operational hazards by detecting early signs of malfunction and taking prompt corrective actions. This is achieved through a series of independent, redundant shutdown mechanisms that are built into the control architecture.

- At the core of the system are several essential protective functions. These include overspeed protection, which monitors the turbine's rotational speed to prevent mechanical failure; overtemperature protection, which ensures the turbine operates within safe thermal limits; and lube oil pressure and temperature monitoring, which protects moving parts from lubrication failure. Additionally, the system monitors for flame loss and high vibration levels, both of which can be early indicators of serious mechanical or combustion issues. These functions work together to maintain the turbine’s operational safety and integrity.

- Beyond these standard protections, the system can be configured to handle application-specific risks. For instance, additional features like combustion system malfunction detection, compressor stall protection, and fire detection can be incorporated depending on the turbine's environment and usage requirements. These capabilities allow the system to be adaptable to a wide range of operational conditions.

- Typically, the protective system is designed to alert operators through alarms when monitored values approach unsafe thresholds. These warnings serve as an early intervention mechanism, allowing operators to assess the situation before the system initiates a full shutdown. If conditions continue to worsen, an automatic shutdown sequence is triggered to prevent further escalation. For maximum safety, a manual emergency shutdown option is also provided, giving operators full control to halt operations immediately if required.

- High system reliability is ensured through extensive redundancy. At least two separate fuel shutoff valves are included in every system, guaranteeing that fuel flow can be reliably stopped even if one valve fails. Similarly, critical parameters are monitored using redundant sensors, allowing the system to cross-verify readings and minimize the risk of false trips. This multi-layered approach enhances the protective system’s dependability and ensures the turbine operates safely under all conditions.

WOC has the largest stock of Speedtronic Mark II Spare Parts and we can repair your faulty spares with a warranty. Our team of experts is available to support your urgent needs related to critical spares, contact us.

FREQUENTLY ASKED QUESTIONS

What is GE Fanuc IC3600VANA1C?

It is an Annunciator Board used in gas turbine control systems.

What is a gas turbine protective system?

A gas turbine protective system is a safety mechanism designed to detect abnormal operating conditions and automatically shut down the turbine to prevent damage or hazardous situations. It includes various sensors, alarms, and redundant shutdown devices.

How does the system know when to shut down the turbine?

The system continuously monitors critical parameters. When values exceed safe operating thresholds, it triggers alarms. If conditions persist or worsen, it initiates a safe and automatic shutdown.

What is the role of redundancy in the protective system?

Redundancy ensures reliability and fault tolerance. For example, dual fuel shutoff valves and redundant sensors are used to ensure the system can perform shutdown operations even if one component fails.