World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

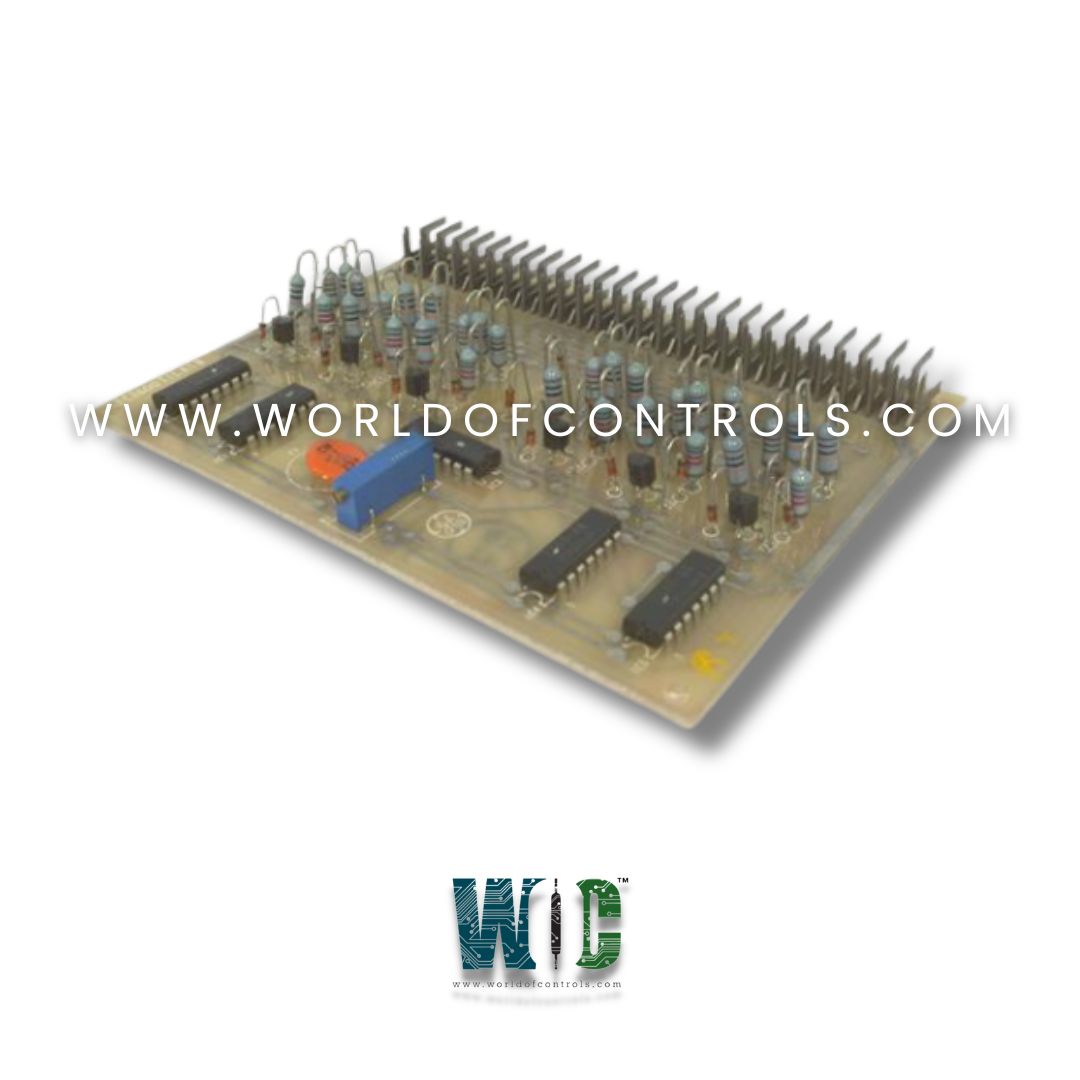

IC3600TILA1B - Inverter Limit Board is available in stock which ships the same day.

IC3600TILA1B - Inverter Limit Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600TILA1B - Inverter Limit Board, contact us and we will get back to you within 24 hours.

Part Number: IC3600TILA1B

Manufacturer: GE Fanuc

Country of Manufacture: United States(USA)

Availability: In Stock

Product Type: Inverter Limit Board

IC3600TILA1B is an Inverter Limit Board manufactured by GE Fanuc. It is a part of Mark I and II control systems. The board regulates and limits the operation of the inverter section within the turbine control framework. It ensures that voltage, current, and frequency outputs remain within specified safety limits, protecting downstream components and maintaining stable system performance.

The sequential system consists of a variety of input and output devices:

WOC has the largest stock of Speedtronic Mark II Spare Parts and we can repair your faulty spares with a warranty. Our team of experts is available to support your urgent needs related to critical spares, contact us.

What is GE Fanuc IC3600TILA1B?

It is an Inverter Limit Board used in gas turbine control systems.

How does the system enhance safety and reliability?

By monitoring vibration levels and sensor integrity in real time, the system ensures that potential issues are detected early. This helps prevent serious mechanical failures, reduces downtime, and supports proactive maintenance efforts.

Can the vibration system shut down equipment automatically?

Yes, in many installations, the system is configured to initiate shutdown protocols when vibration levels exceed critical thresholds, thereby protecting the equipment from further damage.