World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

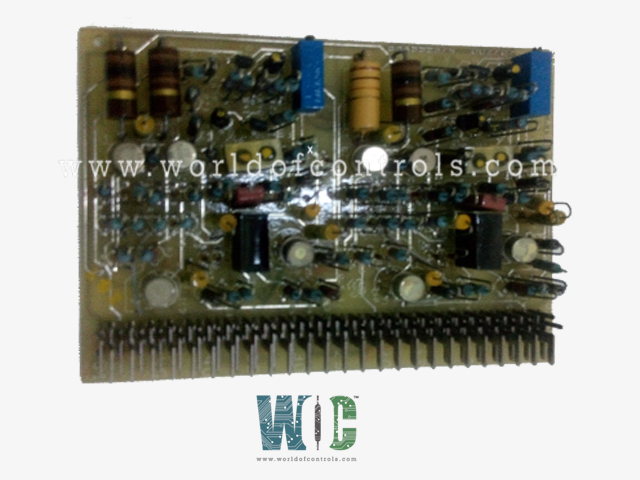

IC3600SVFA1B1B - Voltage to Frequency Converter Module (0- 10V) is available in stock which ships the same day.

IC3600SVFA1B1B - Voltage to Frequency Converter Module (0- 10V) comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SVFA1B1B - Voltage to Frequency Converter Module (0- 10V), contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IC3600SVFA1B1B

Manufacturer: GE Fanuc

Series: Mark II

Operating Power Supply: 9-24VDC

Input Voltage: 0- 5V, 0-10VDC

Input selection: 0- 5V input

Output driving mode: 1-30VDC

Size: 26x23x10mm

Humidity: 80% R.H

Operating temperature: -10 to +60 Deg C

Output Frequency: 0-1 KHz, 0- 10 KHz

Signal Output Duty Cycle: 50%

Product Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600SVFA1B1B is a Voltage to Frequency Converter Module (0- 10V) manufactured and designed by General Electric is part of the Mark I & II Series used in gas turbine control systems. A Voltage to Frequency (V/F) Converter Module is an electronic device that translates a voltage input signal (typically in the range of 0–10V) into a proportional frequency output. This type of module is commonly used in industrial automation systems, signal transmission applications, and process control environments. By converting analog voltage signals into frequency, it allows accurate transmission over long distances without degradation, and provides compatibility with frequency-based input systems such as PLCs or digital counters. The linear relationship between input voltage and output frequency ensures precise control and monitoring.

INSTALLATION:

The module is typically DIN rail or panel-mounted and requires a 24V DC power supply. Connect the 0–10V input signal from your analog source (such as a sensor or transmitter) to the input terminals, and the frequency output to your receiving equipment, such as a PLC or display unit. Ensure all wiring is secure and observe proper polarity to avoid damaging the module. It is also important to check grounding and shielding in high-noise environments to prevent signal interference.

OPERATION:

The module operates by continuously monitoring the input voltage and generating a corresponding frequency output. For example, a 0V input may result in 0 Hz output, while 10V could yield 10 kHz, depending on the module’s range settings. The relationship is typically linear, allowing real-time tracking and control. Some advanced models may include trim pots or digital settings to adjust the scaling factor and zero offset, enabling custom calibration to meet specific application needs. The output is often a square wave signal, easily read by digital systems.

COMPATIBILITY:

These V/F Converter Modules are compatible with a wide range of industrial and commercial systems, particularly those using PLCs, microcontrollers, data acquisition systems, and frequency-based digital indicators. They are suitable for use with sensors, transmitters, and controllers that produce a standard 0–10V output. Their frequency output can easily be interpreted by most modern digital systems, making them a flexible interface between analog and digital domains. Before installation, ensure the module’s frequency output range aligns with the specifications of your receiving device.

WOC maintains the largest inventory of Replacement Parts for GE Speedtronic Turbine Control Systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is the typical frequency output range for a 0–10V input?

The frequency output range varies by module design but is commonly set between 0 to 10 kHz or 0 to 5 kHz. This means a linear relationship, where 1V corresponds to 1 kHz (in a 0–10 kHz module), unless otherwise scaled or configured.

What type of output signal does the module generate?

The module typically outputs a square wave frequency signal, often with a 50% duty cycle. The signal is TTL or open collector, depending on the model, and is compatible with most digital input terminals of PLCs and counters.

How accurate is the voltage-to-frequency conversion?

Accuracy depends on the internal reference stability, temperature drift, and component tolerances. Most high-quality modules offer linearity error within ±0.1% to ±0.5% of full scale, ensuring consistent performance across the entire voltage range.