World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

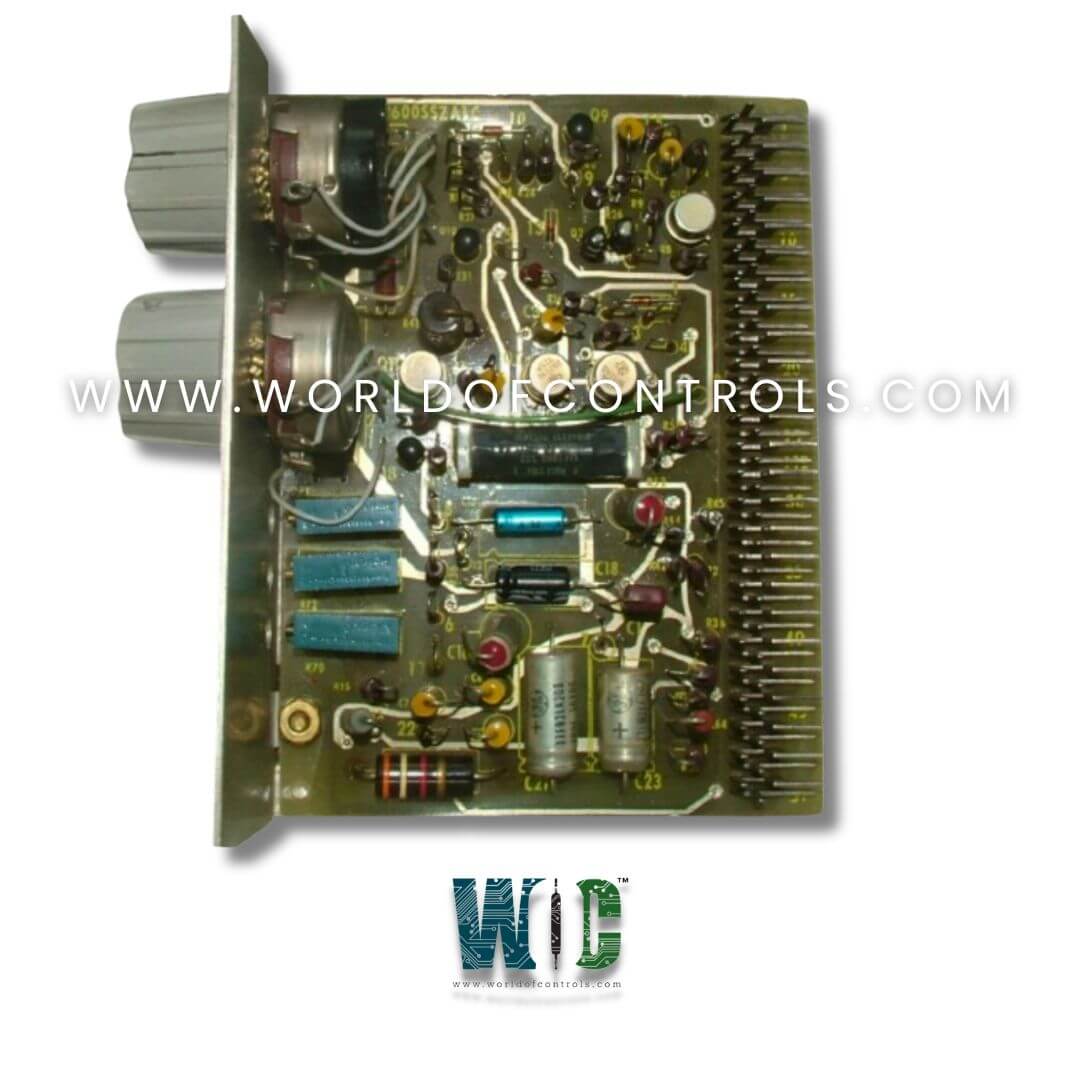

IC3600SSZA1C - PCB Component is available in stock which ships the same day.

IC3600SSZA1C - PCB Component comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SSZA1C - PCB Component, contact us and we will get back to you within 24 hours.

Part No: IC3600SSZA1C

Manufacturer: General Electric

Function: PCB Component

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600SSZA1C is a PCB Component developed by GE. It is a part of Mark I and II control system. The control system is a comprehensive and advanced control technology used in gas turbines, developed by General Electric (GE). This system is designed to optimize the performance, safety, and reliability of the turbine, integrating sophisticated features to monitor and control various operational parameters.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600SSZA1C?

It is a PCB Component developed by GE.

How does the Minimum VCE System prevent flame-out?

The system continuously monitors and controls the Valve Control Electrical (VCE) signal, ensuring that enough fuel is supplied to the turbine, even during cutback conditions. This prevents the turbine from losing combustion and shutting down unexpectedly.

What is Manual VCE Control, and when is it used?

Manual VCE Control allows operators to manually adjust the fuel flow during critical operations, such as during initial startup or when troubleshooting. This feature provides greater control over turbine acceleration, loading, and performance during special conditions.