World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

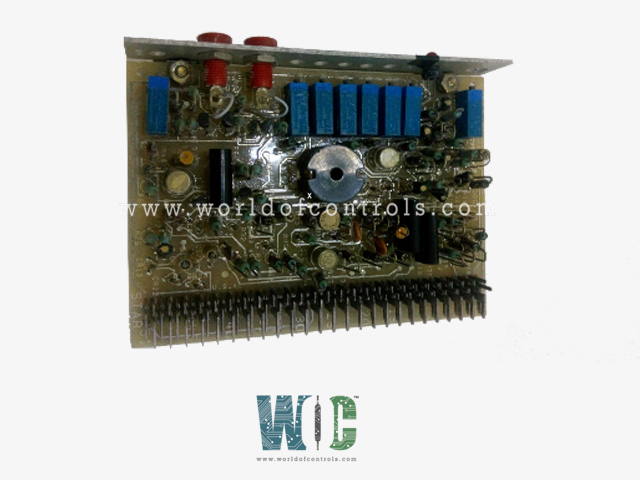

IC3600SSVD1J1B - Servo Drive Control Board is available in stock which ships the same day.

IC3600SSVD1J1B - Servo Drive Control Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SSVD1J1B - Servo Drive Control Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IC3600SSVD1J1B

Manufacturer: GE Fanuc

Series: Mark II

Product Type: Servo Drive Control Board

Input Signal Range: ±5V

Input Voltage: 0- 5V, 0-10VDC

Feedback Input: 4–20 mA

Operating Temperature: –20°C to +60°C

Size: 26x23x10mm

Connector Type: 90-pin edge connector

Output Frequency: 0-1 KHz, 0- 10 KHz

Weight: 200–300 grams

Product Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600SSVD1J1B is a Servo Drive Control Board manufactured and designed by General Electric is part of the Mark I & II Series used in gas turbine control systems. This board is engineered to interface with servo actuators for precise control of turbine-related mechanical functions such as fuel valve positioning, guide vane actuation, or other load-regulating elements. It is an analog control board, designed for real-time signal processing and control within high-temperature and high-vibration industrial environments. The IC3600SSVD1J1B incorporates components to manage signal integrity, suppress transients, and allow field calibration for tuning system responses.

OPERATION:

The IC3600SSVD1J1B operates as a closed-loop analog servo driver. It accepts low-level control signals from the main controller and modulates them into a proportional output to drive turbine actuators. Signal conditioning is achieved via passive components such as resistors, capacitors, and inductors, with transient suppression handled by metal oxide varistors (MOVs). Five trimmable potentiometers allow for calibration of gain, offset, or feedback sensitivity, enabling precise tuning of servo response characteristics. The board ensures minimal phase lag and stable control output, even under varying load or input conditions.

COMPATIBILITY:

The signal interface includes feedback loops and reference signal pathways designed to close the control loop with field-mounted actuators. It does not incorporate any digital communication protocols and is therefore incompatible with later-generation systems (Mark IV, Mark V, Mark VI/VIe), which utilize serial data buses (e.g., ARCNET or Ethernet) and microprocessor-based logic control.

WOC maintains the largest inventory of Replacement Parts for GE Speedtronic Turbine Control Systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is the function of a servo drive control board?

A servo drive control board receives command signals and regulates power to servo actuators. It ensures precise control of position, velocity, or torque in automation systems.

What type of input signals does it support?

It typically supports analog inputs in the range of ±5V or ±10V. These signals determine the desired operation mode and control level of the actuator.

What types of feedback signals are accepted?

The board can process analog feedback like 4–20 mA current loops or 0–10V signals. These inputs help maintain closed-loop accuracy and control system stability.