World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3600SSFG1A1B - Solenoid Filter Board is available in stock which ships the same day.

IC3600SSFG1A1B - Solenoid Filter Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SSFG1A1B - Solenoid Filter Board, contact us and we will get back to you within 24 hours.

Part Number: IC3600SSFG1A1B

Manufacturer: GE Fanuc

Country of Manufacture: United States(USA)

Availability: In Stock

Product Type: Solenoid Filter Board (SCB)

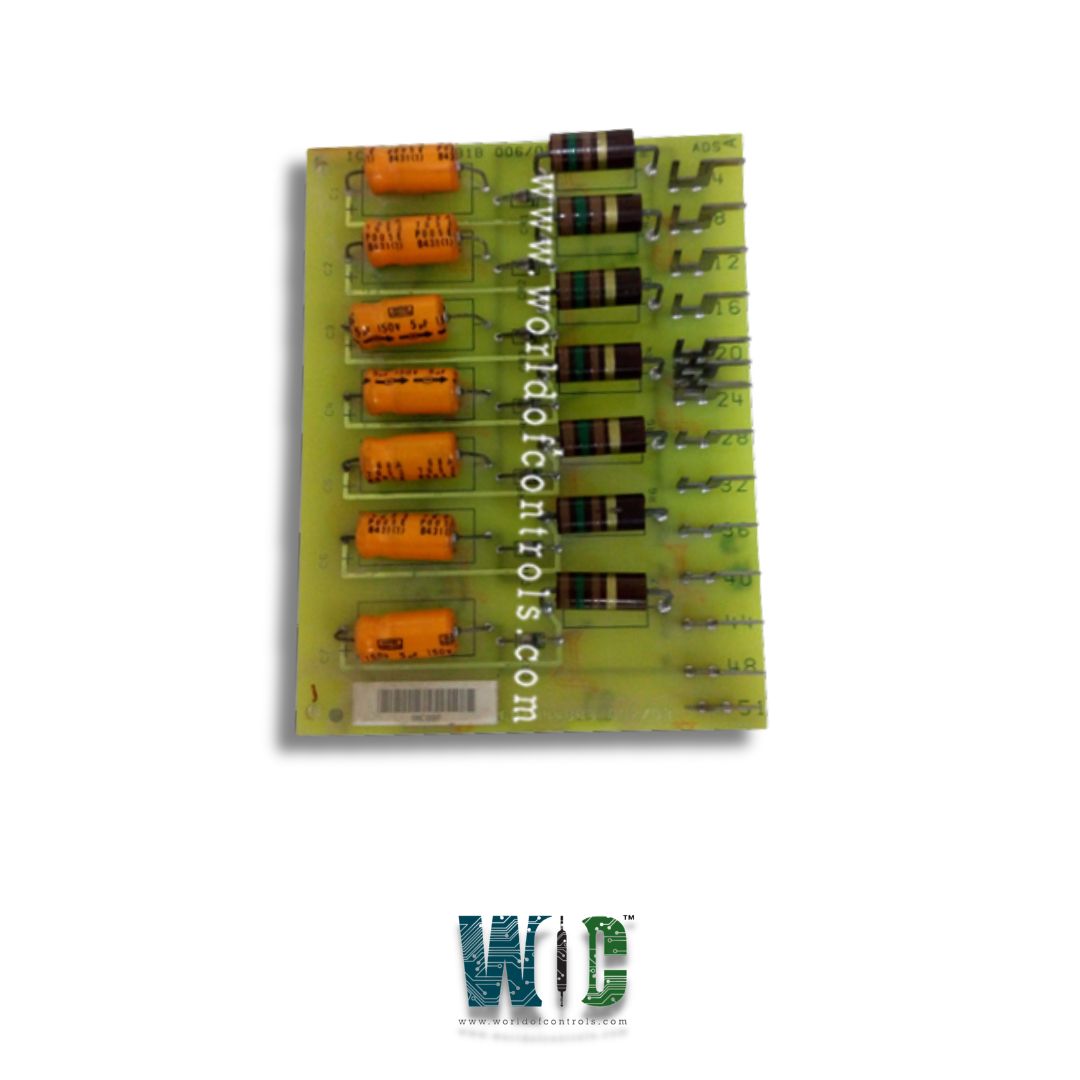

IC3600SSFG1A1B is a Solenoid Filter Board manufactured by GE Fanuc. It is a part of Mark I and II used in gas turbine control systems. This board is a part of the system filtering electrical signals associated with solenoid actuators. Solenoids are often used in turbine systems to actuate valves or switches rapidly, and any electrical noise or spikes in the control circuit could cause erratic behavior or system faults. Ensures clean and stable signal transmission, thereby enhancing the reliability of solenoid-driven operations.

Like any prime mover and its driven load, a gas turbine system must be safeguarded against a variety of potentially damaging operational conditions. These protections are essential not only for preventing mechanical failure but also for ensuring safety, extending equipment lifespan, and minimizing downtime. The protective measures for gas turbines can be broadly divided into two categories:

These are basic, direct-acting protective inputs generated by field devices such as pressure switches, limit switches, or electromechanical relays. They are designed to detect clear, predefined fault conditions and initiate immediate shutdown or trip actions to protect critical components. Common examples include:

These protections require continuous monitoring, sensing technology, and advanced logic to evaluate system behavior under a variety of operating conditions. Unlike simple trip signals, these parameters are often analog-based and involve thresholds, trends, or rate-of-change analysis. Key examples include:

These complex protections are typically integrated into the turbine control system or safety logic processors, often with programmable thresholds, delay timers, and redundancy to ensure safe and reliable turbine operation.

WOC has the largest stock of Speedtronic Mark II Spare Parts and we can repair your faulty spares with a warranty. Our team of experts is available round the clock to support your urgent needs related to critical spares, contact us.

What is GE Fanuc IC3600SSFG1A1B?

It is a Solenoid Filter Board used in gas turbine control systems.

What are simple trip signals in turbine protection?

Simple trip signals are straightforward inputs from devices like pressure switches and relays that trigger immediate shutdowns for faults such as low lube oil pressure or high compressor discharge pressure.

What are complex protective parameters?

It involves continuous monitoring and advanced logic to detect issues like overspeed, overtemperature, vibration, and loss of flame, which require a nuanced response beyond simple on/off signals.