World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

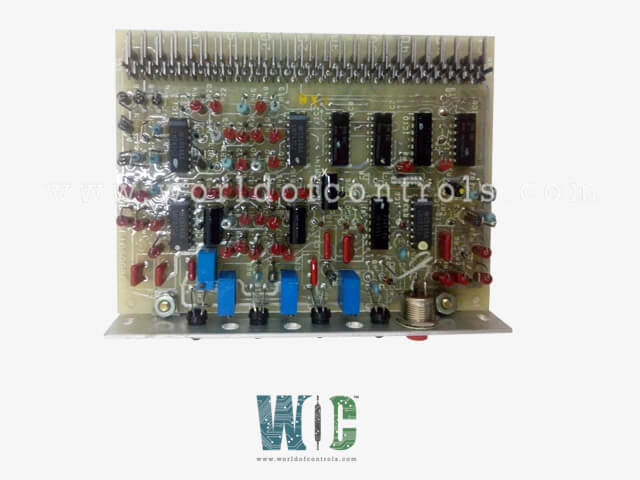

IC3600SOTH1J - Over Temperature Relay Card is available in stock which ships the same day.

IC3600SOTH1J - Over Temperature Relay Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SOTH1J - Over Temperature Relay Card, contact us and we will get back to you within 24 hours.

Part Number: IC3600SOTH1J

Manufacturer: GE Fanuc

Country of Manufacture: United States(USA)

Availability: In Stock

Product Type: Over Temperature Relay Card (SCB)

IC3600SOTH1J is an Over Temperature Relay Card manufactured by GE Fanuc. It is a part of Mark I and II used in gas turbine control systems. The card is primarily responsible for monitoring temperature conditions in the turbine system and activating protective measures when temperatures exceed safe operational thresholds. It plays a crucial role in preventing equipment damage due to overheating by triggering alarms, system shutdowns, or control interventions based on preset limits.

WOC has the largest stock of Speedtronic Mark II Spare Parts and we can repair your faulty spares with a warranty. Our team of experts is available round the clock to support your urgent needs related to critical spares, contact us.

What is GE Fanuc IC3600SOTH1J?

It is an over-temperature relay card used in gas turbine control systems.

What is the purpose of the temperature loop in a gas turbine control system?

The temperature loop regulates the start-up and operating temperatures of the gas turbine to ensure they remain within safe limits, protecting the turbine and extending equipment life.

Why is exhaust temperature used instead of turbine inlet temperature?

Exhaust temperature is used because it allows for easier sampling, longer sensor life, and better serviceability. It also indirectly reflects turbine inlet temperature and helps maintain it within safe limits through system calibration.

Is turbine inlet temperature important for gas turbine operation?

Yes, turbine inlet temperature is critical, especially for components like first-stage nozzles and buckets. However, it's more difficult to measure directly, so the system uses exhaust temperature as a reliable alternative.