World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

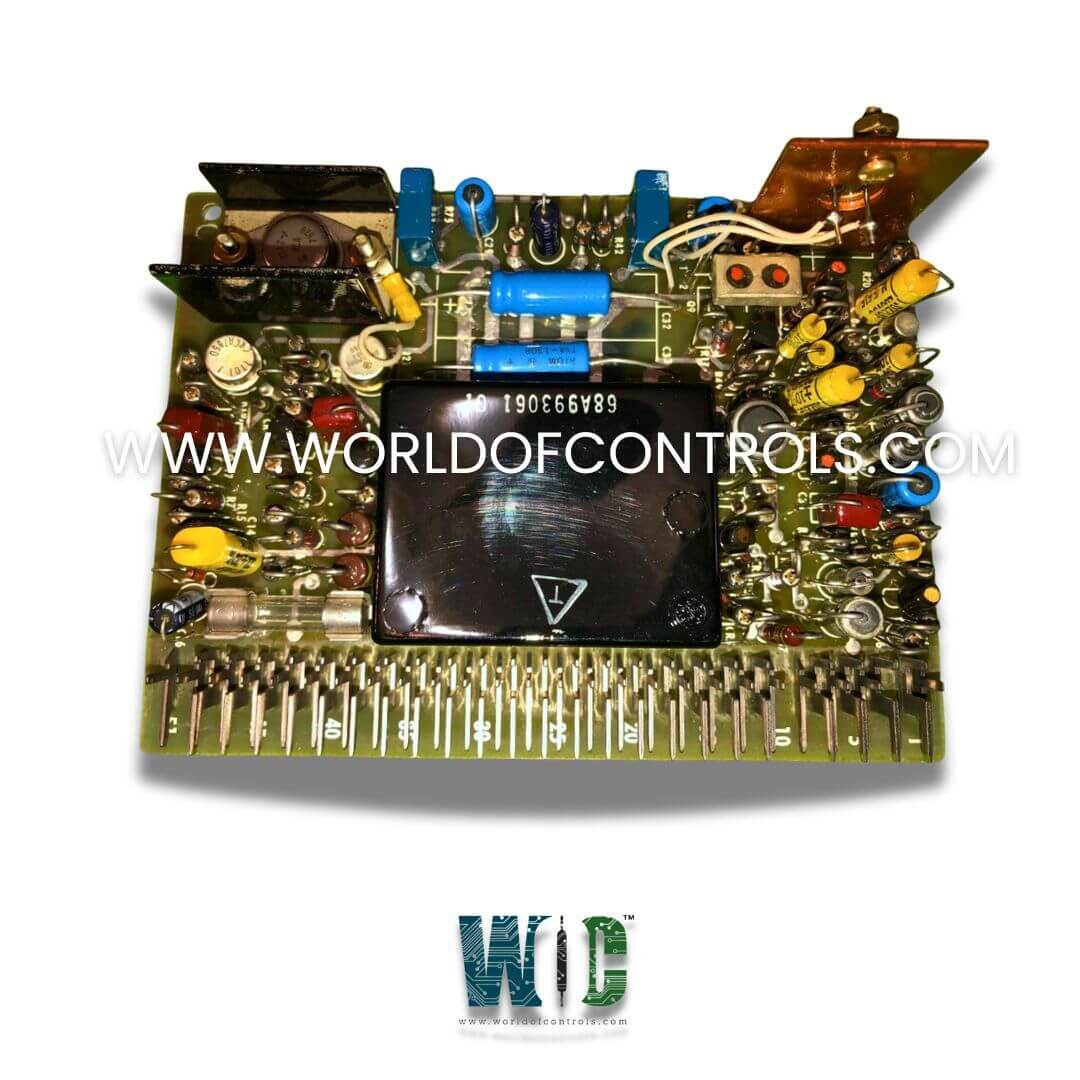

IC3600SOSF1E - LVDT Oscillator Card is available in stock which ships the same day.

IC3600SOSF1E - LVDT Oscillator Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SOSF1E - LVDT Oscillator Card, contact us and we will get back to you within 24 hours.

Part No: IC3600SOSF1E

Manufacturer: General Electric

Function: LVDT Oscillator Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600SOSF1E is a LVDT Oscillator Card developed by GE. It is a part of Mark I and II control system. It is designed to provide the excitation signal required to operate LVDT-based position sensors, which are commonly used for accurate measurement of valve positions and other linear displacements in turbine applications.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600SOSF1E?

It is a LVDT Oscillator Card developed by GE.

What is the first out flashing feature?

The first out flashing feature highlights the first fault or abnormal condition that occurs by flashing its indicator. This assists operators in quickly identifying and troubleshooting the initial cause of a problem.

Can the control system accommodate different fuel types?

Yes, the system is designed to support various fuel combinations, allowing flexibility for applications that may use gas, liquid fuels, or mixtures thereof.

How does the monitoring and recording system help with regulatory compliance?

It continuously monitors turbine operating parameters related to emissions control and records the data, providing documented proof of compliance with environmental regulations during operation.