SPECIFICATIONS

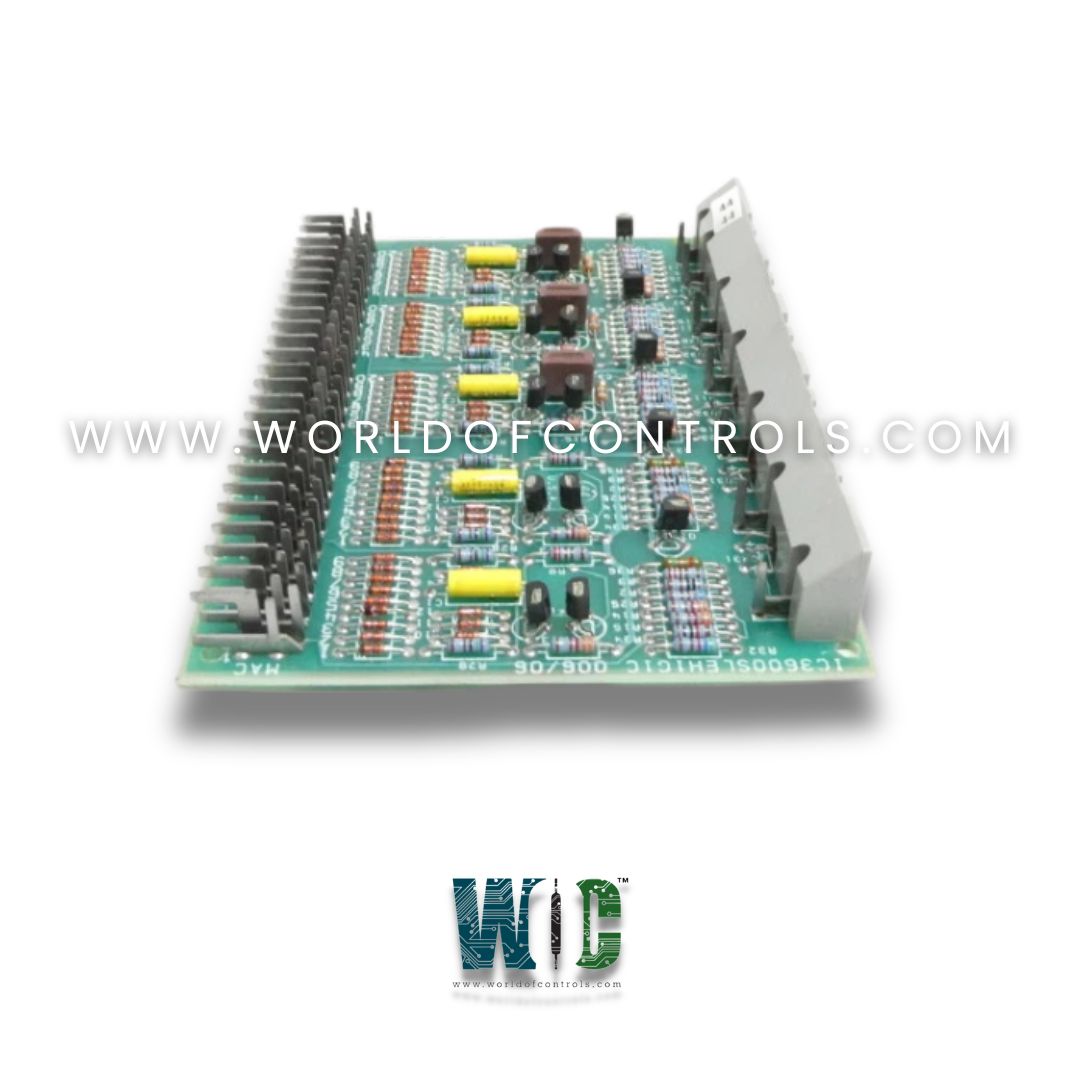

Part Number: IC3600SLEH1C

Manufacturer: GE Fanuc

Country of Manufacture: United States(USA)

Availability: In Stock

Product Type: Logic Element Card (SCB)

Functional Description

IC3600SLEH1C is a Logic Element Card manufactured by GE Fanuc in the series of Mark II used in gas turbine control systems. This Logic Element Card is engineered to handle logical control functions, such as interlocks, sequencing, and state-based decision-making within the Mark II system. It processes input signals and generates corresponding logical outputs based on predefined logic conditions that are critical for turbine operation, protection, and control.

Features

- The card includes a long metal strip mounted along its left edge, which likely serves both structural and grounding purposes. This design enhances physical durability and ensures stable mounting within the control panel or rack.

- Five (5) large red LEDs (Light-Emitting Diodes) are evenly distributed along the metal strip. These LEDs provide real-time visual status indicators, allowing technicians to quickly assess the operational status or logic state of the card during system diagnostics and troubleshooting.

- Like other cards in the IC3600 series, this module is plug-in replaceable, making it easy to swap during maintenance or in the event of component failure, reducing downtime in turbine operations.

Mark I and II Fuel Control System

- The fuel control system is essential in modulating fuel flow to the gas turbine, responding directly to the VCE (Valve Control Electrical) command signal generated by the turbine’s control unit. This system is designed to support various configurations, operating effectively on liquid fuel, gas fuel, or both in dual-fuel applications.

- In heavy-duty gas turbines, the liquid fuel system utilizes a positive-displacement fuel pump coupled with a bypass valve to regulate flow. By adjusting this bypass valve—either opening or closing—it controls the volume of fuel directed to the turbine. Closing the valve increases flow into the combustion chambers, while opening it reduces it. To ensure equal distribution of fuel across multiple combustion chambers, a mechanical flow divider is used. This component consists of gear pump/motor elements—each corresponding to one chamber—with identical displacement. During operation, some elements act as pumps, while others serve as motors, maintaining equal flow rates even when slight pressure differences occur at the nozzles. The rotational speed of the flow divider serves as a feedback signal, enhancing control precision.

- In the LM2500 gas turbine, a different strategy is employed. Fuel flow is modulated using a fuel control valve, while a bypass valve maintains a constant pressure differential across it. This setup allows fuel flow to remain proportional to the valve’s position command, simplifying control logic. Because of the annular combustor design and the use of thirty fuel nozzles, a mechanical flow divider is unnecessary, as even distribution is inherently achieved.

- The gas fuel system uses a dual-valve configuration to manage a wide range of fuel flow conditions. This includes a speed-ratio/stop valve, which sets the inter-stage gas pressure (P2) in proportion to the turbine’s speed (particularly the compressor speed in two-shaft units). This valve works within a control loop to maintain stability. Downstream, a gas control valve precisely adjusts the final flow rate into the turbine. Together, these valves ensure safe, accurate, and responsive gas fuel management, aligning with turbine operating conditions.

WOC has the largest stock of Speedtronic Mark II Spare Parts and we can repair your faulty spares with a warranty. Our team of experts is available to support your urgent needs related to critical spares, contact us.

FREQUENTLY ASKED QUESTIONS

What is GE Fanuc IC3600SLEH1C?

It is a Logic Element Card used in gas turbine control systems.

What is the primary function of the fuel control system in a gas turbine?

The fuel control system regulates the fuel delivered to the turbine’s combustion chambers. It adjusts fuel flow based on control signals to ensure efficient combustion, stable operation, and response to load changes.

How does the liquid fuel system work in heavy-duty turbines?

It uses a positive-displacement pump and a bypass valve. Closing the bypass valve increases fuel flow to the combustion chambers. A mechanical flow divider ensures equal fuel distribution across all combustion chambers by synchronizing flow through gear-driven pump/motor units.

What is the purpose of the flow divider?

The flow divider ensures that each combustion chamber receives an equal amount of fuel. It uses mechanically coupled gear elements to balance the flow, even if individual nozzle pressures vary slightly.