World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

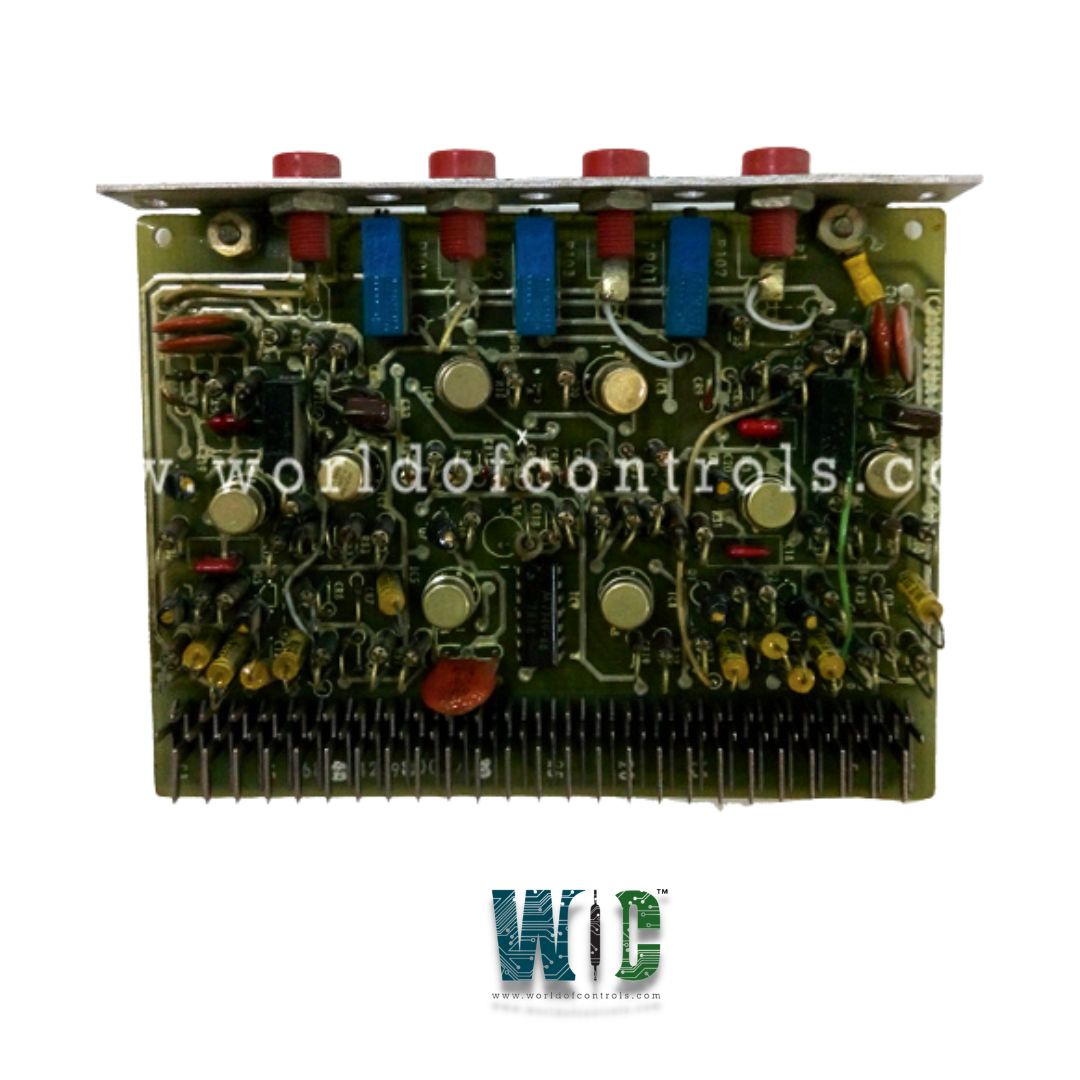

IC3600SFUA1C - Gas Turbine Fuel Flow Control Card is available in stock which ships the same day.

IC3600SFUA1C - Gas Turbine Fuel Flow Control Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SFUA1C - Gas Turbine Fuel Flow Control Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3600SFUA1C

Manufacturer: General Electric Fanuc

Product Lifecycle: Discontinued By Manufacturer

Power Supply: +24 VDC

Input Signals: 4-20 mA

Output Signals: 4-20 mA

Communication Interfaces: Backplane bus

Mounting Type: Plug-in module

Processing Unit: 32-bit microcontroller

Operating Temperature: –20°C to +70°C

Weight: 0.13 lbs

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600SFUA1C is a Gas Turbine Fuel Flow Control Card manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. Its primary function is to regulate the flow of fuel to the combustion section in precise proportion to turbine speed, load demand, and ambient operating conditions. By ensuring accurate metering of fuel, the card maintains stable combustion, efficient performance, and safe turbine operation under all load conditions. The card receives analog and digital input signals from various sensors, including fuel flow transmitters, pressure sensors, and temperature probes. These signals are processed by the onboard microprocessor using a closed-loop Proportional-Integral-Derivative (PID) control algorithm. The control output, typically a 4-20 mA or pulse-width modulated (PWM) signal, is sent to the servo valve or fuel metering valve actuator to adjust the fuel flow rate in real time.

SIGNAL ACQUISITION AND PROCESSING:

The Fuel Flow Control Card acquires real-time data from multiple field sensors that monitor the turbine’s fuel system parameters. These include fuel flow transmitters, pressure sensors, temperature probes, and valve position feedback devices. The incoming analog signals, typically in the 4–20 mA range, are first conditioned through filtering and isolation circuits to eliminate electrical noise and ensure accurate measurement. The conditioned signals are then converted to digital form using high-resolution A/D converters and processed by the onboard microprocessor.

CONTROL OUTPUT AND FUEL REGULATION:

The card produces analog or pulse-width modulated (PWM) output signals that drive the fuel metering or servo valves. These valves adjust the fuel flow to the combustion chamber, ensuring that the turbine receives the exact amount of fuel required for stable and efficient operation. The control output is continuously modulated in real time to maintain the proper fuel-to-air ratio during all operating phases—startup, acceleration, and load changes. The card also compensates for variations in fuel pressure, temperature, and turbine speed to prevent over-fueling or combustion instability.

STARTUP AND ACCELERATION CONTROL:

During turbine startup and acceleration, the Fuel Flow Control Card manages fuel delivery according to a carefully defined schedule to ensure safe and stable operation. The card gradually increases fuel flow to the combustor in a controlled ramp, preventing flameout, over-temperature, or excessive pressure rise. As the turbine accelerates, the card continuously monitors inputs such as fuel flow, temperature, and speed, and dynamically adjusts the fuel rate to match the turbine’s transient conditions.

COMMUNICATION AND INTERFACE:

The board interfaces with the main turbine control system through high-speed communication channels, such as a backplane bus, RS-485, or Ethernet, depending on the system configuration. It exchanges real-time data, including fuel flow commands, sensor feedback, status information, and alarm conditions, with higher-level controllers or Human-Machine Interfaces (HMIs).

WOC maintains the largest inventory of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems, ensuring you get the components you need to keep your operations running without interruption. Beyond supplying brand-new parts, we also repair faulty boards and provide reconditioned or rebuilt boards, all backed by a dependable warranty. Our team of experts is available 24/7 to offer technical support, guidance, and solutions for any turbine control or automation requirement. Whether you need parts replacement, board repairs, or system troubleshooting, WOC is dedicated to delivering fast, reliable, and efficient service. For pricing, availability, or expert consultation, contact our team via phone or email.

What is the primary function of the Fuel Flow Control Card?

The card regulates fuel delivery to the turbine combustor, maintaining an optimal fuel-to-air ratio for stable combustion, efficient performance, and safe operation across all load conditions. It adjusts fuel flow dynamically based on real-time sensor feedback and control commands.

Which sensors and signals does the card interface with?

It receives analog signals (4–20 mA) from fuel flow transmitters, pressure sensors, and temperature probes, as well as digital feedback from valve position sensors and interlocks. These signals are processed in real time to compute precise fuel control outputs.

What communication options are supported?

The card interfaces via a backplane bus, RS-485, or Ethernet, supporting Modbus or proprietary protocols. It exchanges control commands, sensor data, status, and alarms with the main turbine control system or HMI.