World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

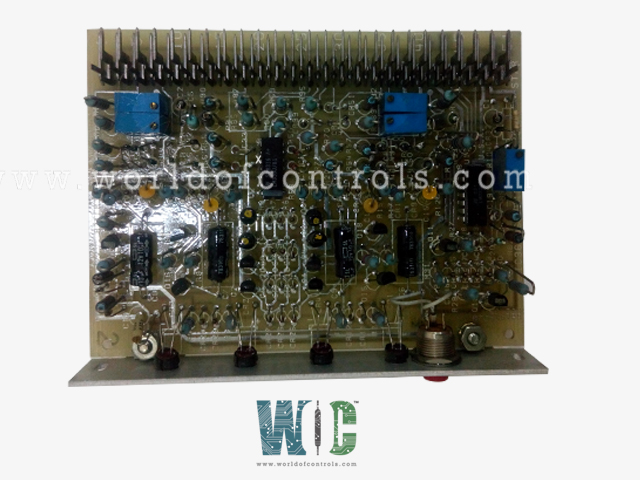

IC3600SBMB1D1D - 12 Voltage/Cell Coil Gas Turbine Monitor Board is available in stock which ships the same day.

IC3600SBMB1D1D - 12 Voltage/Cell Coil Gas Turbine Monitor Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SBMB1D1D - 12 Voltage/Cell Coil Gas Turbine Monitor Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3600SBMB1D1D

Manufacturer: General Electric

Product Type: 12 Voltage/Cell Coil Gas Turbine Monitor Board

Series: Mark II

Power Consumption: 5W to 10W

Voltage Input Range: 0-600V AC/DC

Current Measurement: 0-20A

Coil Inductance Measurement: 0.01 H

Resistance Measurement: 0.1 Ω to 10 kΩ

Temperature Input Range: -40°C to 120°C

Voltage Measurement Accuracy: ±0.5%

Power Supply Voltage: 24 V dc

Board Size: 2.5 cm high x 8.5 cm

Weight: 500g

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600SBMB1D1D is a 12 Voltage/Cell Coil Gas Turbine Monitor Board manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. A 12 Voltage/Cell Coil Gas Turbine Monitor Board is a component used in gas turbine power plants to monitor and control the operation of the gas turbine. The VPC Coil is a critical part of the gas turbine control system, and its associated monitor board helps ensure that the turbine operates safely and efficiently. The VPC Coil typically measures the voltage across individual cells in a gas turbine's combustion system. This information is essential for monitoring and adjusting the combustion process to optimize performance and reduce emissions. The monitor board collects and processes data from the VPC Coil and provides real-time feedback to the control system. The features of a 12 Voltage/Cell Coil Gas Turbine Monitor Board typically include:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Voltage/Cell Coil Gas Turbine Monitor Board?

A Voltage/Cell Coil Gas Turbine Monitor Board is a specialized electronic device designed to monitor and control the electrical performance of gas turbine systems. It tracks voltage levels, assesses coil health, and ensures optimal operational conditions to enhance turbine efficiency and reliability.

What functions does the monitor board perform?

The monitor board performs several critical functions, including voltage monitoring, cell coil monitoring, data logging, alarm and fault detection, temperature monitoring, control signal generation, user interface visualization, integration with control systems, testing and calibration, and compliance reporting.

How does voltage monitoring work?

Voltage monitoring involves measuring the voltage levels across the turbine's coils using integrated sensors. This data is continuously analyzed to ensure the voltage remains within specified limits, helping to identify fluctuations that could indicate electrical issues.