World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

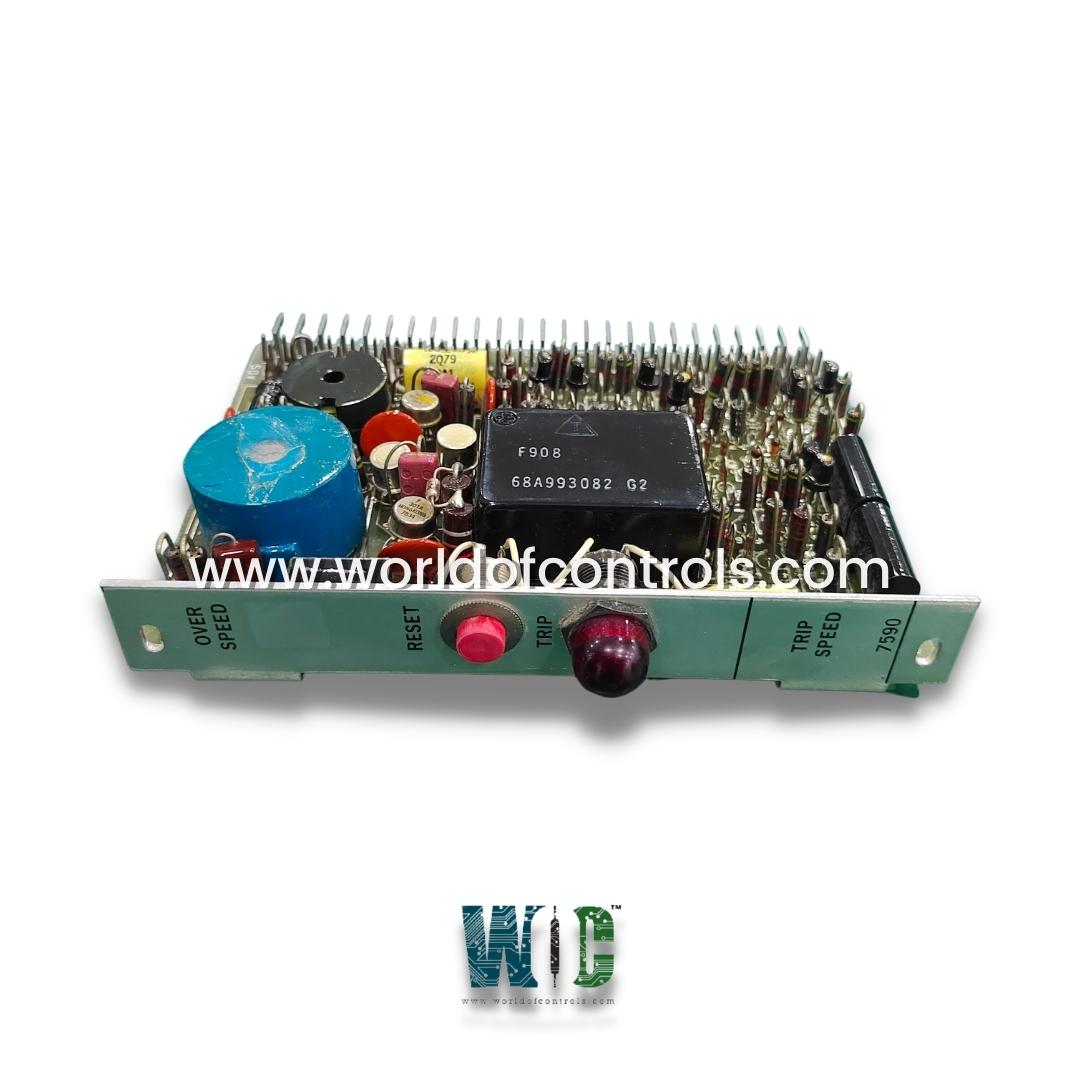

IC3600QOXC4F1B - Overspeed Control Sensor Card is available in stock which ships the same day.

IC3600QOXC4F1B - Overspeed Control Sensor Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600QOXC4F1B - Overspeed Control Sensor Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3600QOXC4F1B

Manufacturer: General Electric

Product Type: Overspeed Control Sensor Card

Series: Mark II

Operating temperature: -40°C to 85°C

Power Supply Voltage: 24 V dc

Voltage Rating: 3.3V, 5V, 12V

Current Rating: Up to 5A

Board Size: 100mm x 80mm

Weight: 0.45 kg

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600QOXC4F1B is an Overspeed Control Sensor Card manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. An overspeed control sensor card is a crucial component in turbine control systems. It monitors the turbine's rotational speed and ensures it stays within safe operational limits. Suppose the turbine exceeds its maximum allowable speed. In that case, the overspeed control sensor card triggers protective measures, such as shutting down the turbine or activating emergency systems to prevent damage or hazardous situations.

WOC has the largest stock of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is an overspeed control sensor card?

An overspeed control sensor card is a device used in turbine systems to monitor and regulate rotational speed, ensuring it does not exceed safe operational limits. If the turbine's speed exceeds these limits, the card triggers protective measures.

Why is overspeed control important?

Overspeed control is crucial for preventing damage to turbines and ensuring safety. Excessive rotational speeds can cause mechanical failure, reduce the lifespan of equipment, or create hazardous conditions.

How does the overspeed control sensor card work?

The card continuously measures the turbine's rotational speed using sensors. It compares this speed to preset limits. If the speed exceeds these limits, the card activates alarms and initiates protective actions such as shutting down the turbine.