World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

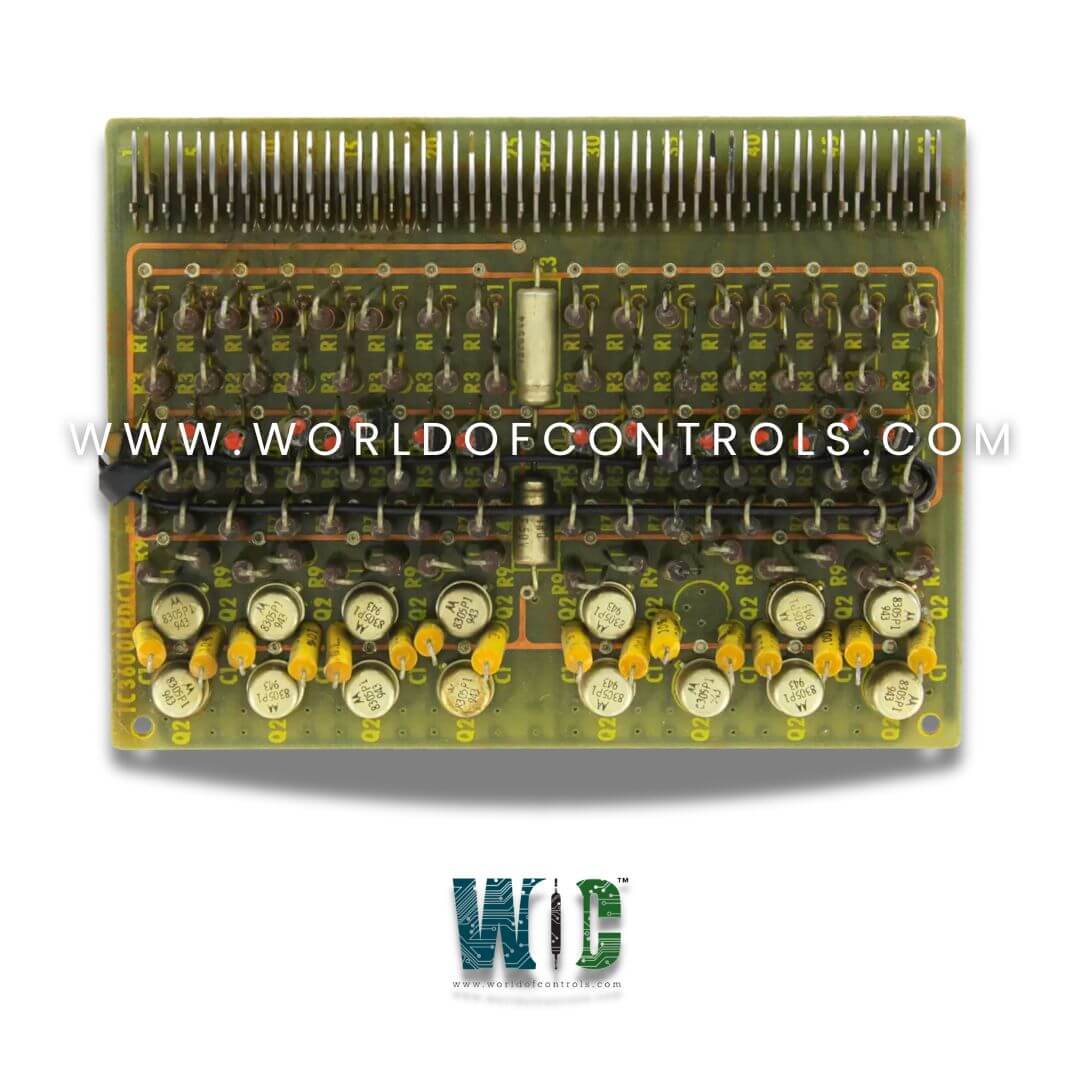

IC3600LRDC1A - Relay Driver Board is available in stock which ships the same day.

IC3600LRDC1A - Relay Driver Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600LRDC1A - Relay Driver Board, contact us and we will get back to you within 24 hours.

Part No: IC3600LRDC1A

Manufacturer: General Electric

Function: Relay Driver Board

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600LRDC1A is a Relay Driver Board developed by GE. It is a part of Mark I and II control system. This board manages and controls the operation of relays within the system, which are essential for executing switching operations, protective functions, and automated control sequences. Receives input signals from the control logic and amplifying them to levels suitable for driving relays.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600LRDC1A?

It is a Relay Driver Board developed by GE.

How are gas turbine operating conditions monitored during normal operation?

Operating conditions are monitored through various meters mounted on the turbine control panel, providing real-time readings of parameters such as temperature, pressure, and turbine speed.

Is manual synchronization and loading possible?

Yes, operators have the option to manually synchronize the generator and manually load it to any desired level, offering flexibility in turbine operations.