World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC3600LCDA1C1B - Clock Logic Driver Control Board is available in stock which ships the same day.

IC3600LCDA1C1B - Clock Logic Driver Control Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600LCDA1C1B - Clock Logic Driver Control Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

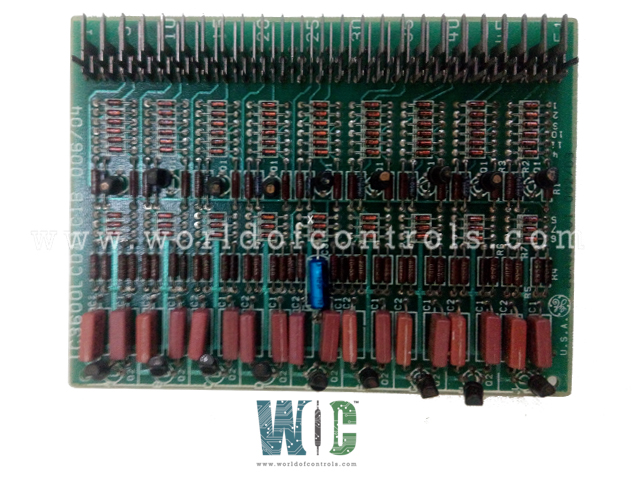

Part Number: IC3600LCDA1C1B

Manufacturer: General Electric

Series: Mark I & II

Product Type: Clock Logic Driver Control Board

Number of relay channels: 12

Power supply voltage: 28 V dc

Operating temperature: -40 to +70°C

Size: 15.9 cm high x 17.8 cm

Weight: 0.8kg

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IC3600LCDA1C1B is a Clock Logic Driver Control Board manufactured and designed by General Electric as part of the Mark I & II Series used in GE Speedtronic Turbine Control Systems. A Clock Logic Driver Control Board is a crucial component in various electronic systems, particularly those that rely on precise timing and synchronization. It is responsible for distributing clock signals across different parts of a circuit or system, ensuring minimal delay and signal degradation. By amplifying and buffering these signals, the board maintains its integrity, allowing multiple components to receive clean and reliable clock inputs. In digital circuits, communication systems, and industrial automation, this board plays a vital role in maintaining synchronization, thereby ensuring coordinated operations. The integration of logic functions within the board also allows for controlled distribution and gating of clock signals based on the system's operational needs. Overall, the Clock Logic Driver Control Board is essential for preventing timing errors and ensuring the seamless functioning of systems that depend on precise timing.

FUNCTIONS:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Clock Logic Driver Control Board?

A Clock Logic Driver Control Board is an electronic component responsible for distributing, amplifying, and synchronizing clock signals across different parts of a circuit or system. It ensures that all components receive precise and reliable timing signals.

How does the board help in reducing noise and jitter?

The Clock Logic Driver Control Board strengthens and buffers clock signals, reducing susceptibility to noise and minimizing jitter, which are vital for maintaining the integrity of high-speed and precise timing signals.

What components are typically found on a Clock Logic Driver Control Board?

The board usually includes clock buffers/drivers, logic gates, phase-locked loops (PLLs), and multiplexers, which work together to manage and distribute clock signals efficiently.