World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

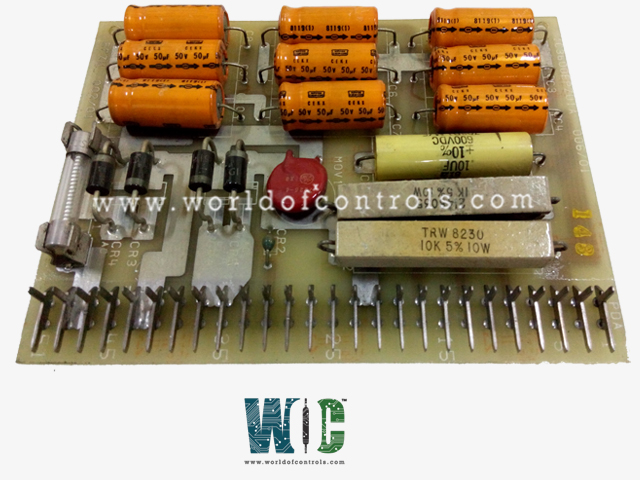

IC3600EPZU1 - Power Supply Regulator Board is available in stock which ships the same day.

IC3600EPZU1 - Power Supply Regulator Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600EPZU1 - Power Supply Regulator Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3600EPZU1

Manufacturer: General Electric

Series: Mark II

Product Type: Power Supply Regulator Board

Input Voltage: 110V AC

Output Voltage: 5V DC, 12V DC

Input Frequency: 50 Hz / 60 Hz

Output Current: 5A, 10A

Power Output: 50W

Mounting Type: DIN Rail

Operating Temperature Range: -10°C to 50°C

Availability: In Stock

Weight: 2.90 lbs

Dimensions: 19.00 x 12.50 x 3.50

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600EPZU1 is a Power Supply Regulator Board manufactured and designed by General Electric is part of the Mark I & II Series used in gas turbine control systems. The board typically manages the conversion of AC (alternating current) to DC (direct current), adjusts the voltage levels, and distributes the power to various subsystems within a machine or control system. In systems like turbines, the Power Supply Regulator Board ensures that each part of the turbine control system, including sensors, actuators, and processors, receives the correct power, thus preventing malfunctions and enhancing the system's longevity.

INSTALLATION:

OPERATION:

WOC maintains the largest inventory of Replacement Parts for GE Speedtronic Turbine Control Systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is a power supply regulator board?

A power supply regulator board is an electronic circuit board that ensures a stable and consistent voltage output, even when the input voltage or load conditions change. It is essential for protecting sensitive electronic components from voltage fluctuations and is commonly used in embedded systems, consumer electronics, and industrial applications.

What are the types of power regulators used on these boards?

Power supply regulator boards typically use either linear regulators or switching regulators. Linear regulators, such as the 7805 or LM317, provide a simple and low-noise solution but are less efficient, especially when there is a significant voltage difference between input and output. Switching regulators, including buck (step-down), boost (step-up), and buck-boost types, are more efficient and suitable for higher power applications, though they generate more electrical noise.

What input voltage range can the board handle?

The input voltage range of a power supply regulator board varies depending on its design and components. Many common boards accept an input voltage ranging from 7V to 35V DC. However, it's important to consult the specific datasheet or manufacturer’s documentation to ensure compatibility with your application.