World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

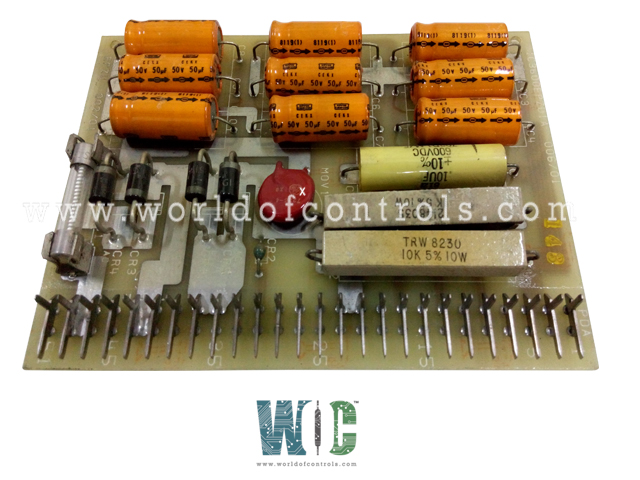

IC3600EPSX1G1G - 12V Lamp Voltage Regulator Circuit Board is available in stock which ships the same day.

IC3600EPSX1G1G - 12V Lamp Voltage Regulator Circuit Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600EPSX1G1G - 12V Lamp Voltage Regulator Circuit Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

Part No: IC3600EPSX1G1G

Manufacturer: General Electric

Function: 12V Lamp Voltage Regulator Circuit Board

Series: Mark I & II

Operating temperature: -35 to 65 ºC

Power Supply Voltage: 25 V dc

Input voltage: DC 3-30V / AC 3-20V

Output voltage: DC 1.25V-28V

Mounting size: 65*32mm / 2.56*1.26in

Board Size: 2.36 x 2.83 x 1.06 inch

Weight: Approx. 43g / 1.5ºz

Availability: In-Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600EPSX1G1G is a 12V Lamp Voltage Regulator Circuit Board manufactured and designed by General Electric as part of the Mark I & II Series used in the GE Speedtronic Control System. It receives a wide input voltage range (DC 3–30V or AC 3–20V) and converts it into a stable regulated DC output ranging from 1.25V to 28V. The regulator maintains constant voltage output under varying load and supply fluctuations, ensuring consistent lamp brightness and preventing voltage-induced lamp failures. The board integrates protection and stabilization circuits to handle transient conditions and maintain voltage regulation within specified operating temperature limits (-35°C to 65°C). It is engineered for high reliability in turbine control environments, providing consistent performance even under changing system conditions.

TYPES OF VOLTAGE REGULATORS:

Linear Voltage Regulators: These are simple and provide a stable output voltage by dissipating excess power as heat. They are ideal for low-power applications where efficiency is not a primary concern.

INSTALLATION:

The board must be secured in its designated rack or chassis slot, ensuring proper alignment with mating connectors and stable mechanical support to prevent vibration-related failures. Electrical connections must be made using the correct input power source (25V DC supply recommended), and the output terminals must be connected to the lamp load with correct polarity and wiring practices. All connections should be verified for correct voltage levels and continuity before energizing. Proper grounding and shielding practices should be followed to minimize electrical noise and ensure stable operation. Ensure the operating environment maintains a temperature within -35°C to 65°C and is free from excessive moisture or contamination that may affect circuit integrity.

OPERATION:

When input voltage varies or load current changes, the regulator compensates to prevent output deviation, ensuring constant lamp voltage. The output voltage can be set within the specified range (1.25V to 28V) and remains stable across the operating temperature range. The board also handles transient input spikes and load surges through its internal filtering and protection circuitry, preventing damage to the lamp load and maintaining stable operation. Any deviation beyond design limits may result in protective shutdown or output regulation loss. Maintaining proper input supply and load conditions is essential for reliable performance.

WOC maintains the largest inventory of GE Speedtronic turbine control system replacement parts, ensuring rapid availability for urgent OEM requirements. In addition to supplying unused and rebuilt boards with warranty support, we also offer professional repair services for faulty modules, helping extend equipment life and reduce downtime. Our experienced technical team is available 24/7 to provide guidance, troubleshooting, and support for all automation needs, including part selection, compatibility verification, and system integration. For pricing, availability, and repair inquiries, please contact our team by phone or email, and we will respond promptly with the best solution for your application.

What are the common causes of failure for this regulator board?

Common failure causes include input voltage spikes, excessive load current, overheating, and aged electrolytic capacitors. Connector corrosion or loose wiring can also lead to intermittent operation. Overvoltage or reverse polarity may damage the internal regulation components. Regular inspection and proper power conditioning can reduce failure risk.

How can I test if the board is functioning correctly?

To test the board, measure the input voltage and verify it falls within the specified range (DC 3–30V / AC 3–20V). Then measure the output voltage under load to ensure it remains stable within the 1.25–28V range. If output is unstable or missing, check for loose connections or damaged components. Using a regulated DC supply and a multimeter is recommended for accurate verification.

What should I check if the lamp is flickering or dimming?

If the lamp flickers or dims, first verify the input supply voltage and ensure it is stable and within range. Next, check the output voltage under load to confirm it remains constant. Inspect wiring connections for loose terminals or high resistance contacts. If input and output are stable, the lamp or its load circuit may be faulty.

How should the board be wired for correct operation?

The board should be wired with correct polarity for DC input, ensuring the positive and negative terminals are connected to the corresponding supply lines. The output should be connected directly to the lamp load with proper gauge wiring to avoid voltage drop. Grounding must be solid and noise-free to prevent signal interference. Ensure connectors are seated properly to avoid intermittent contact.