World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

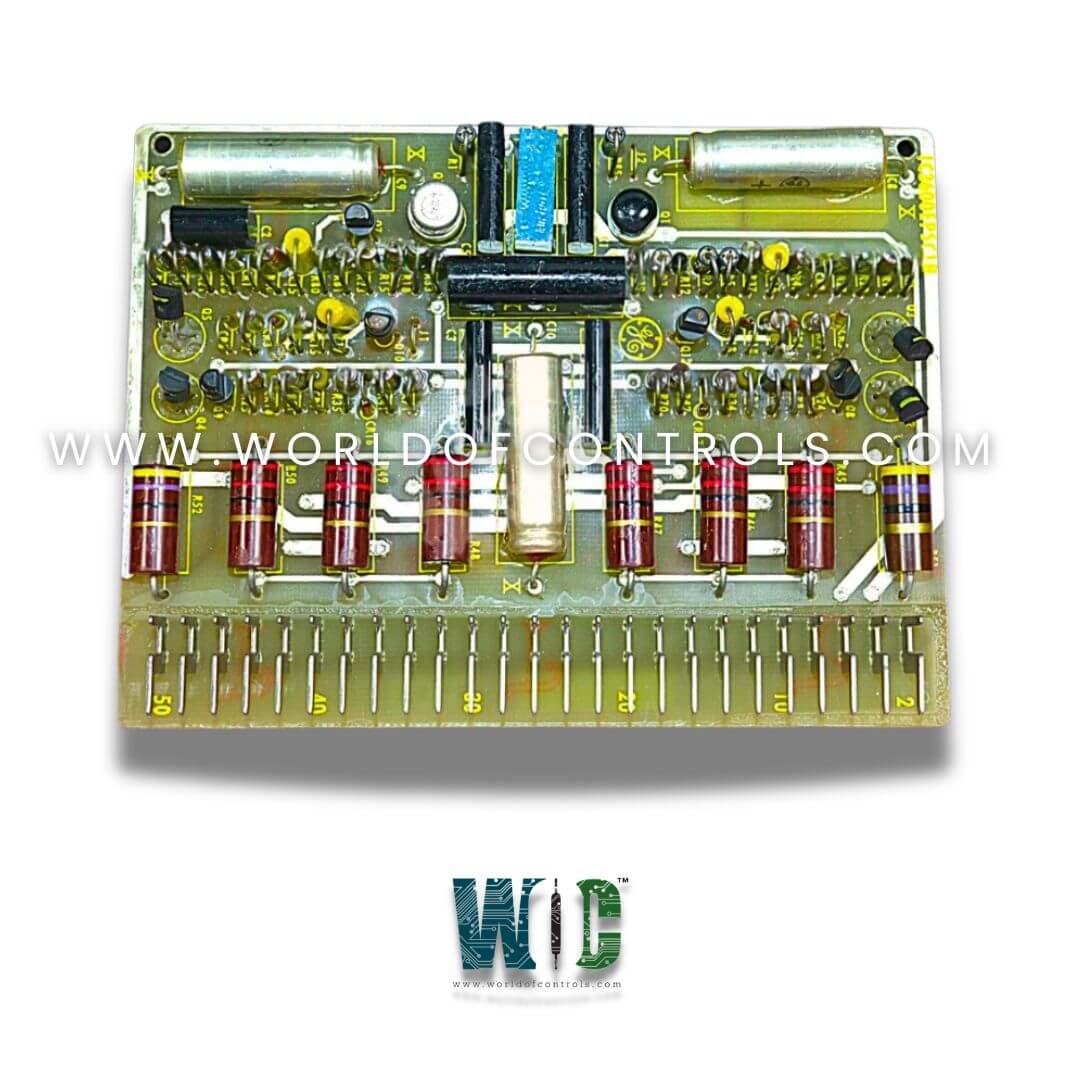

IC3600EPSC1B1B - Inverter Drive Card is available in stock which ships the same day.

IC3600EPSC1B1B - Inverter Drive Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600EPSC1B1B - Inverter Drive Card, contact us and we will get back to you within 24 hours.

Part No: IC3600EPSC1B1B

Manufacturer: General Electric

Function: Inverter Drive Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600EPSC1B1B is an Inverter Drive Card developed by GE. It is a part of Mark I and II control system. This board manages the drive signals for inverter modules, enabling precise switching required for converting DC to AC, which is essential for driving motors and other AC-powered components.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600EPSC1B1B?

It is an Inverter Drive Card developed by GE.

How are system operating conditions monitored?

Conditions are monitored using panel-mounted meters and indicator lights. In systems equipped with ITS (Integrated Turbine Supervisory), detailed operational data and trends can also be accessed in real time.

What happens if there’s a failure during startup?

The control system halts the startup sequence and activates annunciator lights to indicate the fault. The first fault will flash, while others remain steady. Once the issue is resolved, all annunciator lights can be reset.

Is it possible to schedule maintenance based on operating data?

Yes. The system includes counters and clocks to track starts, stops, and run hours, assisting in scheduled maintenance planning and operational analysis.