SPECIFICATIONS

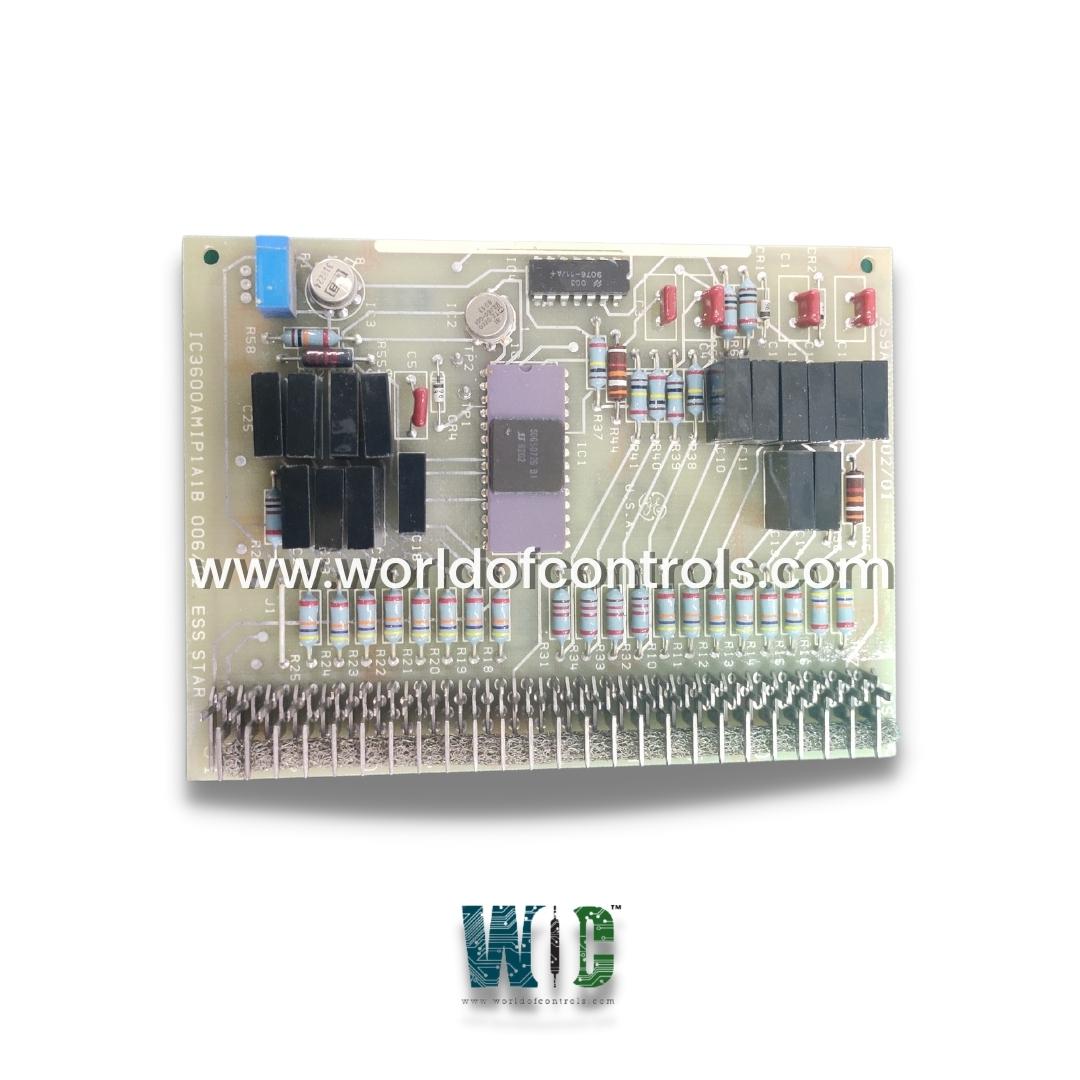

Part No.: IC3600AMIP1A

Manufacturer: General Electric

Product Type: Single End Multiplex Board

Availability: In Stock

Series: VersaMax

Functional Description

IC3600AMIP1A is a single-end multiplex Board developed by GE. It is a part of GE Mark I and II series. The board is responsible for multiplexing analog input signals, allowing multiple sensor or instrumentation signals to be routed through a single data acquisition channel. This helps reduce the number of wiring paths and simplifies the overall control system architecture.

Features

- A single-ended signal is one where the voltage is measured concerning a common ground. Only one conductor carries the signal, and the return path is the system ground. This is in contrast to differential signals, which use two conductors to carry the signal as a voltage difference between them.

- Multiplexing (MUX) allows multiple input signals to share a single output line or device by switching rapidly between them. It reduces the number of connections required for data acquisition or control systems.

- The Single-End Multiplex Board is used to select one signal at a time from a group of analog inputs (like temperature, pressure, or speed signals).

- Transmit the selected signal to the controller for processing.

- Reduce wiring complexity and hardware costs.

- Maintain signal fidelity in systems where grounding and isolation are properly managed.

System Features

- The turbine control system is engineered to be self-checking and fault-tolerant, ensuring both high operational reliability and stringent safety standards. At startup, the system automatically performs comprehensive diagnostics on critical subsystems—such as flame detectors, overspeed protection, and overtemperature sensors. If any of these components, particularly those with redundant (dual-channel) configurations, are found to have failed, the startup sequence is immediately aborted to prevent unsafe conditions.

- Once the turbine is operational, the system continues to monitor its health in real time. If a failure occurs in one of the redundant protective channels during normal operation, the system will trigger an alarm to alert operators, but the turbine will continue running, preserving uptime. This design ensures that a single point of failure does not cause unnecessary shutdowns. However, if both redundant protective channels fail, indicating a total protection loss, the system will initiate an automatic shutdown to safeguard both the turbine and its surroundings.

- This approach strikes a careful balance—maximizing operational reliability while preserving safety in the event of critical failures.

- In addition to protecting the turbine itself, the control system also monitors and safeguards the driven equipment, which have its protection requirements. These include:

- Vibration monitoring to detect mechanical imbalances or bearing wear,

- Low lubrication oil pressure to prevent damage from inadequate lubrication,

- Electrical protection relays for generator-driven applications, and

- High temperature protection in gas compressors and other load equipment.

- The control system hardware is also protected. For example, if a power supply failure is detected within the control system, a safe machine shutdown is automatically triggered to avoid uncontrolled operation or equipment damage.

- Through this multi-layered approach to diagnostics, redundancy, and protective logic, the system ensures a high level of availability without compromising safety under any condition.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IC3600AMIP1A?

It is a Single End Multiplex Board developed by GE.

What happens if a failure is detected during startup?

If one of the critical or redundant protective systems fails during startup, the startup sequence is aborted. This prevents the turbine from running under unsafe conditions.

What if a failure occurs while the turbine is already running?

If only one of the redundant protective channels fails during normal operation, an alarm is triggered to alert operators, but the turbine continues running. If both redundant channels fail, the system initiates an automatic shutdown to ensure safety.

Why use redundant protective channels?

Redundant channels provide backup protection. This ensures that if one channel fails, the other can continue to protect the turbine, improving system reliability while maintaining safety.