World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

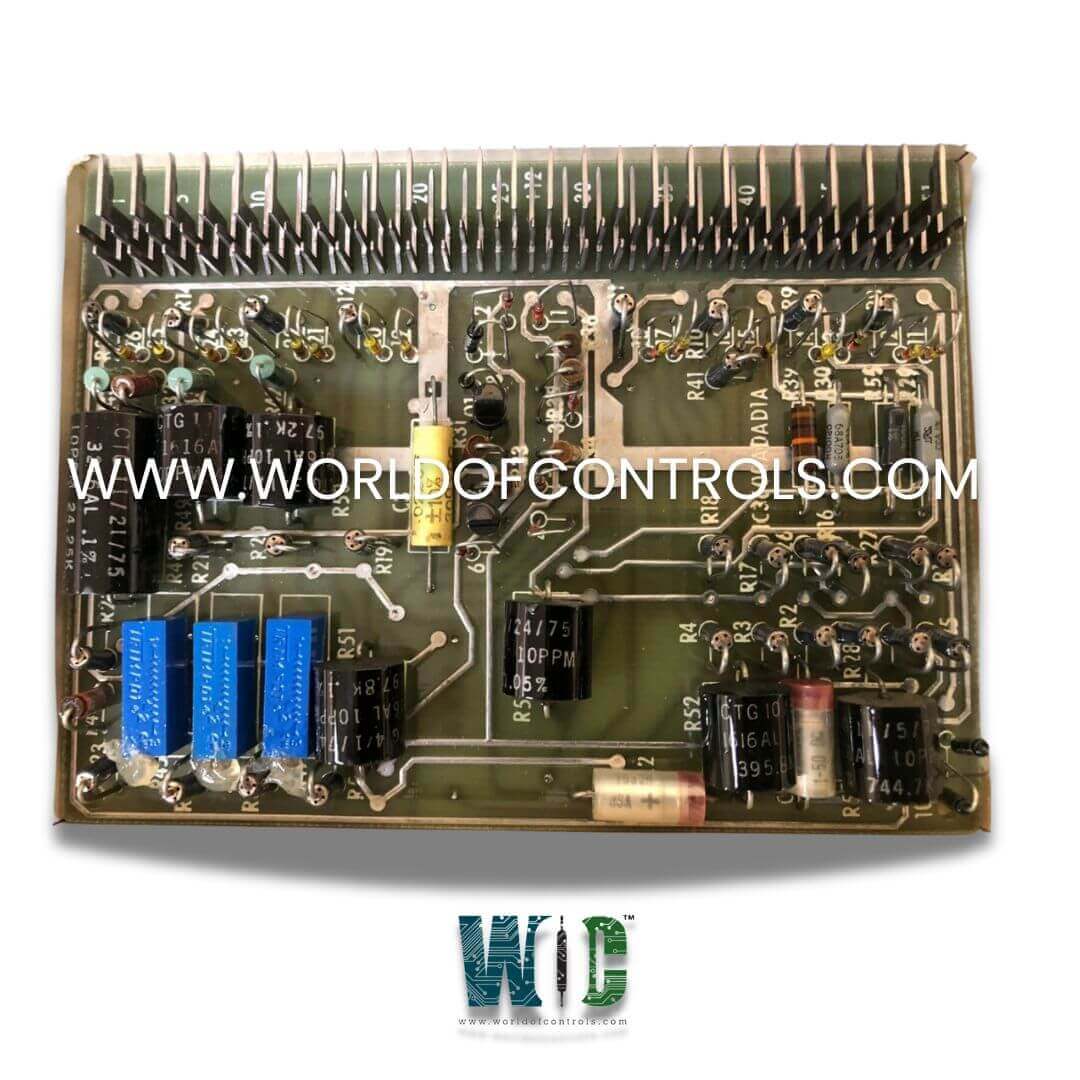

IC3600ADAD1A - D/A Diode Converter Card is available in stock which ships the same day.

IC3600ADAD1A - D/A Diode Converter Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600ADAD1A - D/A Diode Converter Card, contact us and we will get back to you within 24 hours.

Part No: IC3600ADAD1A

Manufacturer: General Electric

Function: D/A Diode Converter Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600ADAD1A is an over-temperature Card developed by GE. It is a part of Mark I and II control system. Designed to monitor exhaust gas temperatures and regulate turbine operation to avoid thermal damage. It is integrated into the system's temperature control loop, which is one of the two main loops in the architecture (the other being the speed loop).

Several engineering considerations support the use of exhaust temperature over turbine inlet temperature:

To ensure accurate temperature control, the system relies on precise exhaust temperature sampling. Extensive factory and field testing, along with statistical analysis, led to the development of the twelve even area sampling criteria. This approach places twelve thermocouples evenly across the exhaust area to achieve:

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600ADAD1A?

It is an Over-temperature Card developed by GE.

Why does the system monitor exhaust temperature instead of turbine inlet temperature?

Exhaust temperature is used as a primary control parameter because it allows for more reliable and durable sensor placement. It provides a representative measurement of turbine performance. It avoids placing sensors in the extreme conditions of the turbine inlet. The system uses calibration and biases to ensure inlet temperatures remain within design limits

What happens when an over-temperature condition is detected?

It processes temperature signals from exhaust thermocouples. If temperatures exceed preset thresholds, it initiates a fuel cutback via the control system to bring temperatures back to safe levels and protect turbine components.