World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

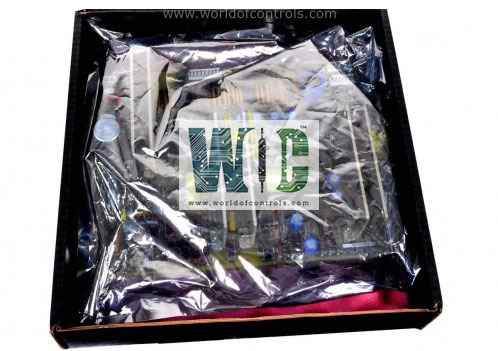

DS4520B1SA - Processor R, S, T, C Module is available in stock which ships the same day.

DS4520B1SA - Processor R, S, T, C Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS4520B1SA - Processor R, S, T, C Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

Part Number: DS4520B1SA

Manufacturer: General Electric

Series: Mark IV

Product Type: Processor R, S, T, C Module

Architecture: Triple Modular Redundant (TMR)

Communication Protocols: RS-232 / RS-485

Communication Interface: High-speed backplane

Processor Channels: R, S, T, C

Function: Monitoring, Control, Protection, Communication

Power Supply: 24V DC

Operating Temperature: 0°C – 70°C

Board Size: 15.7 cm High x 18.5 cm

Isolation Voltage: 1500 VAC

Repair: 3-7 Days

Weight: 2.00 lbs

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS4520B1SA is a Processor R, S, T, C Module manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic turbine control systems. It forms part of a Triple Modular Redundant (TMR) architecture, comprising three independent processors (R, S, T) and a communications processor (C) to enhance system reliability. The module performs critical tasks, including monitoring turbine parameters such as speed, temperature, and pressure, controlling operations to maintain optimal performance, providing protection by detecting and responding to faults, and facilitating communication between processors and external systems through RS-232 or RS-485 interfaces. Its modular design allows for easy maintenance, upgrades, and ensures continuous operation even if one processor fails, making it essential for the safe and efficient functioning of gas and steam turbines.

OPERATION:

The Processor R, S, T, C Module operates as the central computational unit in the GE Speedtronic control system, executing all turbine sequencing, protection, and monitoring functions. The module employs a Triple Modular Redundancy (TMR) design across the R, S, and T processors, with the C processor functioning as a comparator for validation and fault detection.

Input signals from turbine field sensors (speed pickups, temperature probes, pressure transducers, etc.) are digitized and transferred to the processor module through associated input cards.

COMPATIBILITY:

The Processor R, S, T, C Module is engineered for seamless integration into GE Speedtronic turbine control platforms, specifically the Mark IV and Mark V series. Its architecture supports multi-channel redundancy and aligns with the communication protocols and backplane interfaces of these systems.

System Integration: Fully compatible with GE Speedtronic Mark IV / Mark V control systems, where it operates as the central processing unit.

World of Controls offers the largest stock of GE Speedtronic Gas Turbine control system replacement parts, including unused and rebuilt boards, all backed by a full warranty. We also provide expert repair services for faulty boards, restoring them to OEM standards to ensure reliable turbine operation. Our team of automation specialists is available 24/7 to support your OEM needs, provide technical guidance, and assist with any control system requirements. For pricing, availability, or technical assistance on parts and repairs, please contact us by phone or email.

What communication method is used between the processors and I/O cards?

The module communicates via the system backplane, using high-speed data transfer for input acquisition, control logic execution, and output signal distribution.

Can this module be used in both gas and steam turbines?

Yes, the Processor R, S, T, C Module is designed for both gas and steam turbine applications, ensuring compatibility across a wide range of industrial and power generation systems.

How does the module ensure output reliability during conflicting processor results?

A voting mechanism compares outputs from R, S, and T channels. The majority result is selected as the valid control output, while the C channel verifies consistency.