World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS210TRESH1A - Small Steam Turbine Emergency Trip Board is available in stock which ships the same day.

IS210TRESH1A - Small Steam Turbine Emergency Trip Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210TRESH1A - Small Steam Turbine Emergency Trip Board, contact us and we will get back to you within 24 hours.

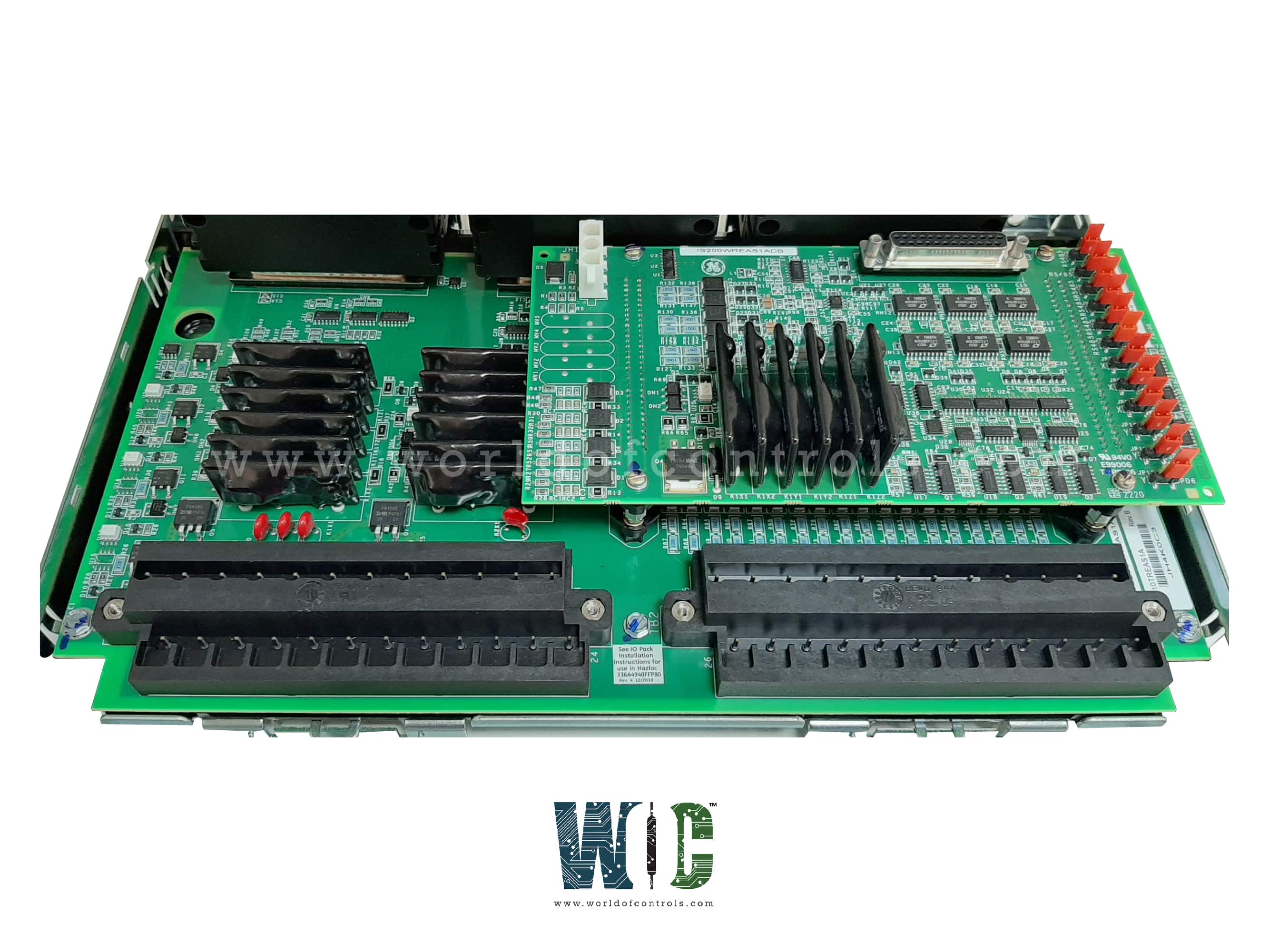

SPECIFICATIONS:

Part Number: IS210TRESH1A

Manufacturer: General Electric

Series: Mark VIe

Number of trip solenoids: 3

Trip Solenoid Rating: 125 V dc

Product Type: Steam Turbine Emergency Trip Terminal Board

Technology: Surface Mount

Common Mode Voltage Range: ±5 V

Dimensions: 17.8 cm wide x 33.02 cm

Operating temperature: 0 to 60 °C

No.of Analog Voltage Inputs: 6

Repair: 3-7 Days

Availability: In Stock

Country of Origin: United States

Manual: GEH-6421M

FUNCTIONAL DESCRIPTION:

IS210TRESH1A is a Steam Turbine Emergency Trip Terminal Board manufactured and designed by General Electric as part of the VIe Series used in GE Distributed Control Systems. TRES is used for emergency overspeed protection for small/medium-sized steam turbines. The I/O controller controls TRES and provides power to three emergency trip solenoids, which can be connected between the TRES and TRPS terminal boards. TRES provides the positive side of the 125 V dc to the solenoids, and TRPS provides the negative side. The I/O controller provides emergency overspeed protection, emergency stop functions, and controls the three relays on TRES, which control the three trip solenoids.

In the TRES, the seven dry contact inputs, excitation, and signal are monitored and fanned to the I/O controller. The board includes the sync check relay driver, K25A, and associated monitoring, the same as on TREG, and the servo clamp relay driver, K4CL, and its associated monitoring. A second TRES board cannot be driven from the I/O controller through J4.

INSTALLATION:

The IS200TRESH1A (TRES) board is connected to the system through two primary I/O terminal blocks and dedicated connectors for power and signal interfaces. The first I/O terminal block is used to wire the three trip solenoids, which form the core of the turbine emergency trip system and are responsible for actuating the hydraulic mechanisms that close steam or fuel valves during fault or overspeed conditions. The second terminal block is designated for up to seven trip interlock inputs, providing critical safety interconnections that monitor turbine operating parameters and ensure proper trip permissive logic. The wiring configuration, as illustrated in the corresponding connection diagram, ensures adequate routing for power and signal paths between the board and external devices. Connector J2 delivers three power buses from the TRPS terminal board, supplying the 125 V DC required for solenoid operation, while connector JH1 provides the excitation voltage used to energize and monitor the seven trip interlock circuits.

OPERATION:

The controller energizes and de-energizes the trip relays on the TRES board based on emergency stop or overspeed conditions, ensuring rapid and reliable actuation of the trip solenoids. In simplex configurations, an additional communication path is provided through a third cable that transmits a trip signal from connector J1 on the TRES board to the TSVO terminal board. This connection enables the servo valve clamp function, which securely holds the servo valve in a clamped position during a turbine trip event, preventing unintended valve movement and ensuring a complete and stable turbine shutdown sequence.

CONTROL OF TRIP SOLENOIDS:

Both TREL and TRES control the trip solenoids 1 and 2 so that either one can remove the power and actuate the hydraulics to close the steam or fuel valves. ETR3 is set up to supply power to trip solenoid #3. The nine trip relay coils on TRES are supplied with 28 V dc from the I/O controller. The trip solenoids are supplied with 125 V dc (or 24 V dc) through plug J2, and draw up to 1 A with a 0.1-second L/R time constant.

SOLENOID TRIP TESTS:

Application software in the controller is used to initiate tests of the trip solenoids. Online tests allow each of the trip solenoids to be manually tripped one at a time, either through the PTR relays from the controller or through the ETR relays from the protection module. A contact from each solenoid circuit is wired back as a contact input to give a positive indication that the solenoid has tripped. Primary and emergency offline overspeed tests are provided too for verification of actual trips due to software-simulated trip overspeed conditions.

WOC offers the largest inventory of GE Distributed Control System (DCS) replacement parts, including new, unused, and fully rebuilt boards backed by a comprehensive warranty. We also provide expert repair services for faulty or damaged boards, restoring them to full OEM specifications. Our team of experienced engineers is available 24/7 to support all automation and control system needs, from technical guidance to troubleshooting, ensuring reliable operation and rapid solutions. For pricing, availability, or service inquiries, contact us directly via phone or email.

What is IS200TRESH1A?

The IS200TRESH1A is a Small Steam Turbine Emergency Trip Board manufactured by General Electric (GE) as part of the Mark VI Control System. It provides emergency overspeed protection and trip functionality by controlling three trip solenoids, working in conjunction with the I/O controller to safely shut down small and medium steam turbines during fault or overspeed conditions.

What are the main functions of the terminal board?

The terminal board receives signals from various sensors monitoring parameters like turbine overspeed, low oil pressure, high vibration, or abnormal temperatures. It processes these signals to activate emergency shutdown mechanisms when necessary.

How many trip solenoids can TRES control?

The board controls three trip solenoids, with each solenoid independently capable of actuating hydraulic mechanisms to close steam or fuel valves during a turbine trip event.