World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

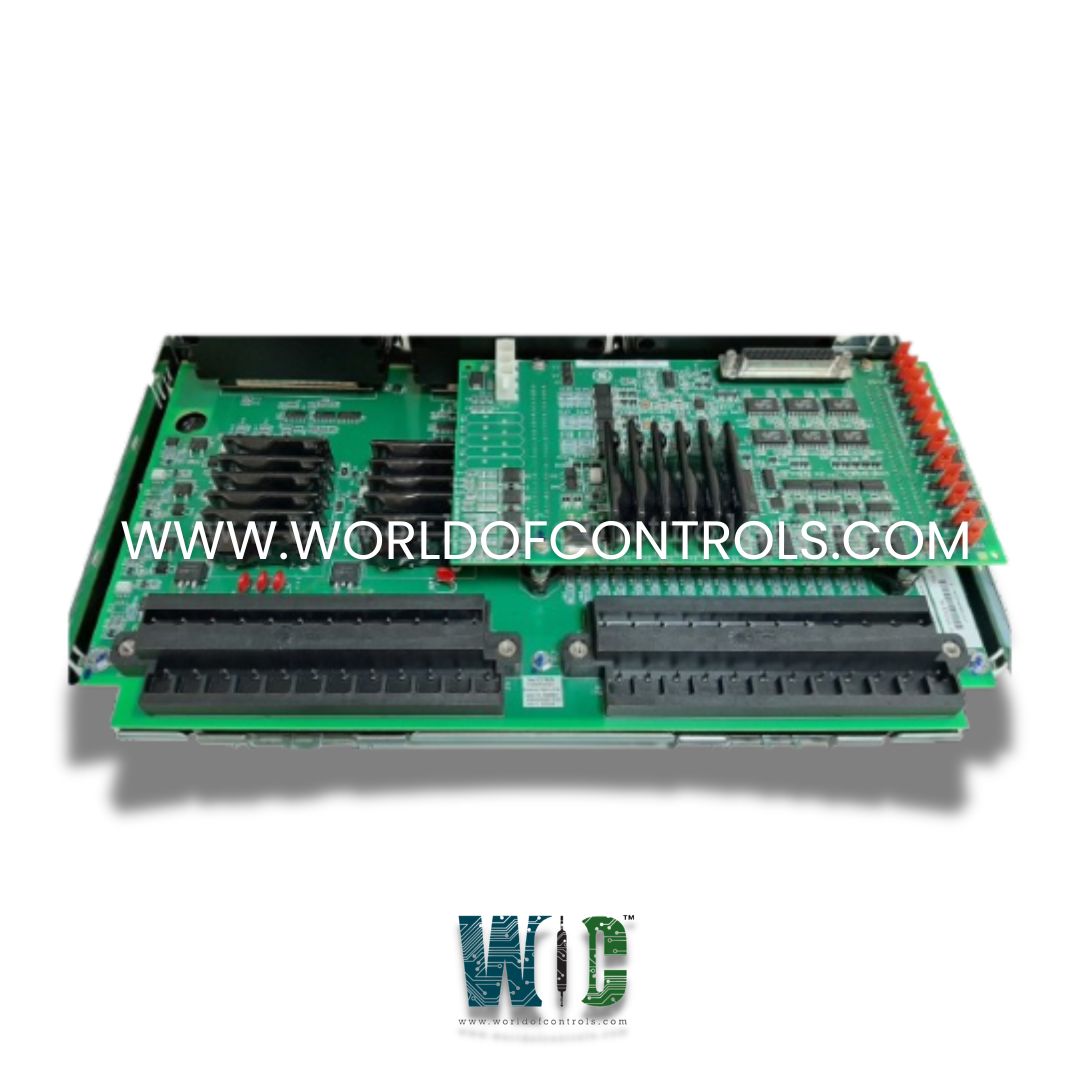

IS210TREGH3B - Turbine Emergency Trip Terminal Board is available in stock which ships the same day.

IS210TREGH3B - Turbine Emergency Trip Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210TREGH3B - Turbine Emergency Trip Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS210TREGH3B

Manufacturer: General Electric

Series: Mark VIe

Product Type: Turbine Emergency Trip Terminal Board

Technology: Surface Mount

Size: 17.8 cm wide x 33.02 cm

Common Mode Voltage Range: ±5 V

Operating temperature: 0 to 65 °C

No.of Analog Voltage Inputs: 6

Repair: 3-7 Days

Weight: 2.00 lbs

Number of trip solenoids: 3

Number of inputs: 6

Availability: In Stock

Country of Origin: United States

Manual: GEH-6421I

FUNCTIONAL DESCRIPTION:

IS210TREGH3B is a Turbine Emergency Trip Terminal Board manufactured and designed by General Electric as part of the VIe Series used in GE Distributed Turbine Control Systems. The TREG module is responsible for supplying power to up to three emergency trip solenoids and operates under the control of the I/O controller. These solenoids are critical components in turbine or generator safety systems, providing a fast-acting mechanism to stop the system during abnormal or emergency conditions, such as overspeed events or other hazardous operating situations.

A maximum of three trip solenoids can be connected between the TREG and TRPG terminal boards. In this configuration, TREG supplies the positive side of the DC power to the solenoids, while TRPG provides the negative side, completing the circuit. The I/O controller plays a pivotal role by delivering emergency overspeed protection, emergency stop functions, and controlling the 12 relays located on the TREG board. Out of these 12 relays, nine are organized into three groups of three relays each, and these groups are responsible for "voting" inputs that determine activation of the three connected trip solenoids. This voting mechanism ensures that the trip solenoids are triggered reliably only when specific safety conditions are met. The TREG board comes in multiple types, each tailored for specific applications and system configurations:

INSTALLATION:

The first I/O terminal block serves as the primary connection point for critical safety and control components in the system. Specifically, the three trip solenoids, which are responsible for rapidly stopping the turbine or generator during emergency conditions, are wired directly to this block. In addition to the trip solenoids, economizing resistors and the emergency stop circuit are also connected here.

OPERATION:

The TREG board operates under complete control of the I/O controller, which manages all of its functions and ensures that safety-critical operations are executed reliably. The TREG itself does not contain autonomous control logic; instead, it acts as an interface for powering and controlling emergency trip solenoids, relays, and feedback circuits, responding solely to commands from the I/O controller. The physical connections between the TREG and the control modules are minimal, reflecting its role as a controlled power interface:

WOC has the largest stock of GE Distributed turbine control system replacement parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is the function of the TREG/TRPG terminal boards?

The TREG/TRPG terminal boards supply power to the emergency trip solenoids and serve as the interface between the solenoids and the I/O controller. TREG provides the positive DC supply, while TRPG provides the negative connection. Together, they ensure that the trip solenoids receive reliable power for emergency turbine shutdowns.

How many trip solenoids can be connected to the TREG/TRPG?

Up to three trip solenoids can be connected, with their activation controlled by a voting relay logic on the TREG board. Each solenoid is linked to a dedicated group of relays that determine when it should activate based on safety inputs from the I/O controller.

How is redundant power implemented on the H1B board?

Control power from connectors JX1, JY1, and JZ1 is diode-combined, providing redundant power paths to the status feedback circuits and economizing relays. This ensures that a single power failure does not compromise board operation.

How is the relay voting logic implemented?

Each trip solenoid is controlled by a 3-of-3 relay voting scheme. The I/O controller provides discrete inputs to each relay group, and the solenoid is energized only when all three relays within a group simultaneously close. This ensures fail-safe operation and prevents spurious trips.