World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS210TREGH2B - Gas Turbine Emergency Trip Terminal Board is available in stock which ships the same day.

IS210TREGH2B - Gas Turbine Emergency Trip Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210TREGH2B - Gas Turbine Emergency Trip Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

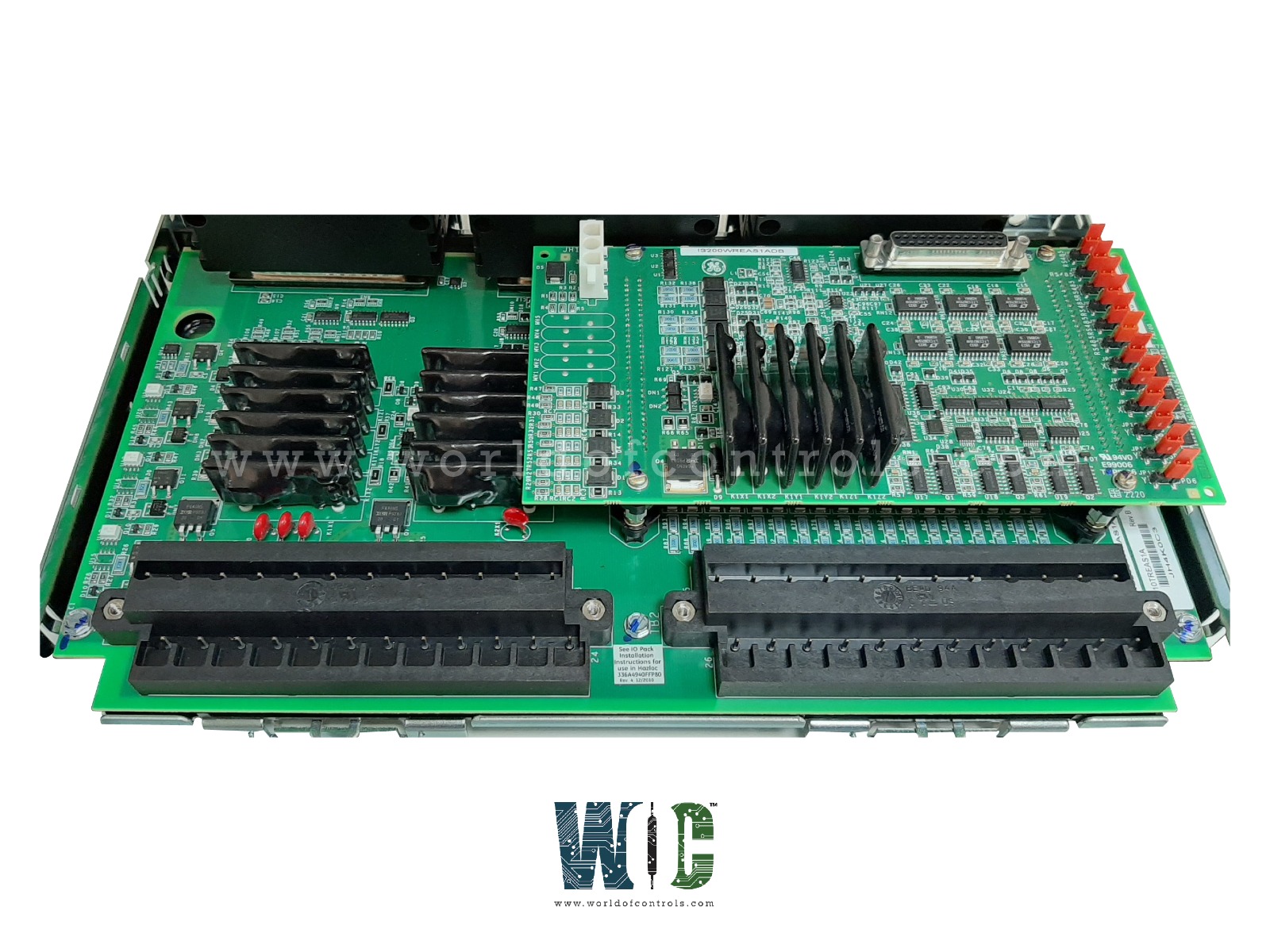

Part Number: IS210TREGH2B

Manufacturer: General Electric

Series: Mark VI

Product Type: Gas Turbine Emergency Trip Terminal Board

Number of trip solenoids: 3

Trip solenoid rating: H1 / S1- 125 V dc

Solenoid inductance: 0.1 sec

Suppression: MOV

Relay outputs: 3

Trip interlock filter: 4 ms

Trip interlock ac voltage rejection: 60 V rms

Trip interlock isolation: 1500 V

Trip inputs: 7

Trip interlock Current: 2.5 mA

Size: 17.8 cm wide x 33.02 cm

Common Mode Voltage Range: ±5 V

Operating temperature: 0 to 65 °C

No.of Analog Voltage Inputs: 6

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721L

FUNCTIONAL DESCRIPTION:

IS210TREGH2B is a Gas Turbine Emergency Trip Terminal Board manufactured and designed by General Electric as part of the VI Series used in GE Speedtronic Gas Turbine Control Systems. The Gas Turbine Emergency Trip (TREG) terminal board provides power to three emergency trip solenoids and is controlled by the I/O pack or control board. Up to three trip solenoids can be connected between the TREG and TRPG terminal boards. TREG provides the positive side of the DC power to the solenoids and TRPG provides the negative side. The I/O pack or control board provides emergency overspeed protection, and emergency stop functions, and controls the 12 relays on TREG, nine of which form three groups of three to vote inputs controlling the three trip solenoids. H1B is the primary version for 125 V DC applications. Control power from the JX1, JY1, and JZ1 connectors are diode combined to create redundant power on the board for status feedback circuits and powering the economizing relays. Power separation is maintained for the trip relay circuits. H2B is used for 24 V DC applications. All other features are the same as H1B.

INSTALLATION:

The three trip solenoids, economizing resistors, and the emergency stop are wired directly to the first I/O terminal block. Up to seven trip interlocks can be wired to the second terminal block.

OPERATION:

TREG is entirely controlled by the PPRO / YPRO I/O pack or IS215VPRO board. The connections to the control modules are the J2 power cable and trip solenoids. In simplex systems, a third cable carries a trip signal from J1 to the TSVO terminal board, which provides a servo valve clamp function upon turbine trip.

CONTROL OF TRIP SOLENOIDS:

WOC has the largest stock of GE Speedtronic gas turbine control system replacement parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is a gas turbine emergency trip terminal board?

A gas turbine emergency trip terminal board is a critical component of a gas turbine control system. It serves as a central hub for emergency shutdown signals and trip commands in the event of a critical fault or hazardous condition.

What is the primary function of the emergency trip terminal board?

The primary function is to rapidly and safely shut down the gas turbine in emergencies to prevent damage to the equipment, personnel, and the surrounding environment.

What are some common signals that trigger an emergency shutdown?

Signals such as high exhaust temperature, low lubricating oil pressure, flame detection failure, overspeed, or any other condition that poses an immediate risk to the turbine operation can trigger an emergency shutdown.