World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS210TPGSH2B - Primary Trip Terminal Board Assembly is available in stock which ships the same day.

IS210TPGSH2B - Primary Trip Terminal Board Assembly comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210TPGSH2B - Primary Trip Terminal Board Assembly, contact us and we will get back to you within 24 hours.

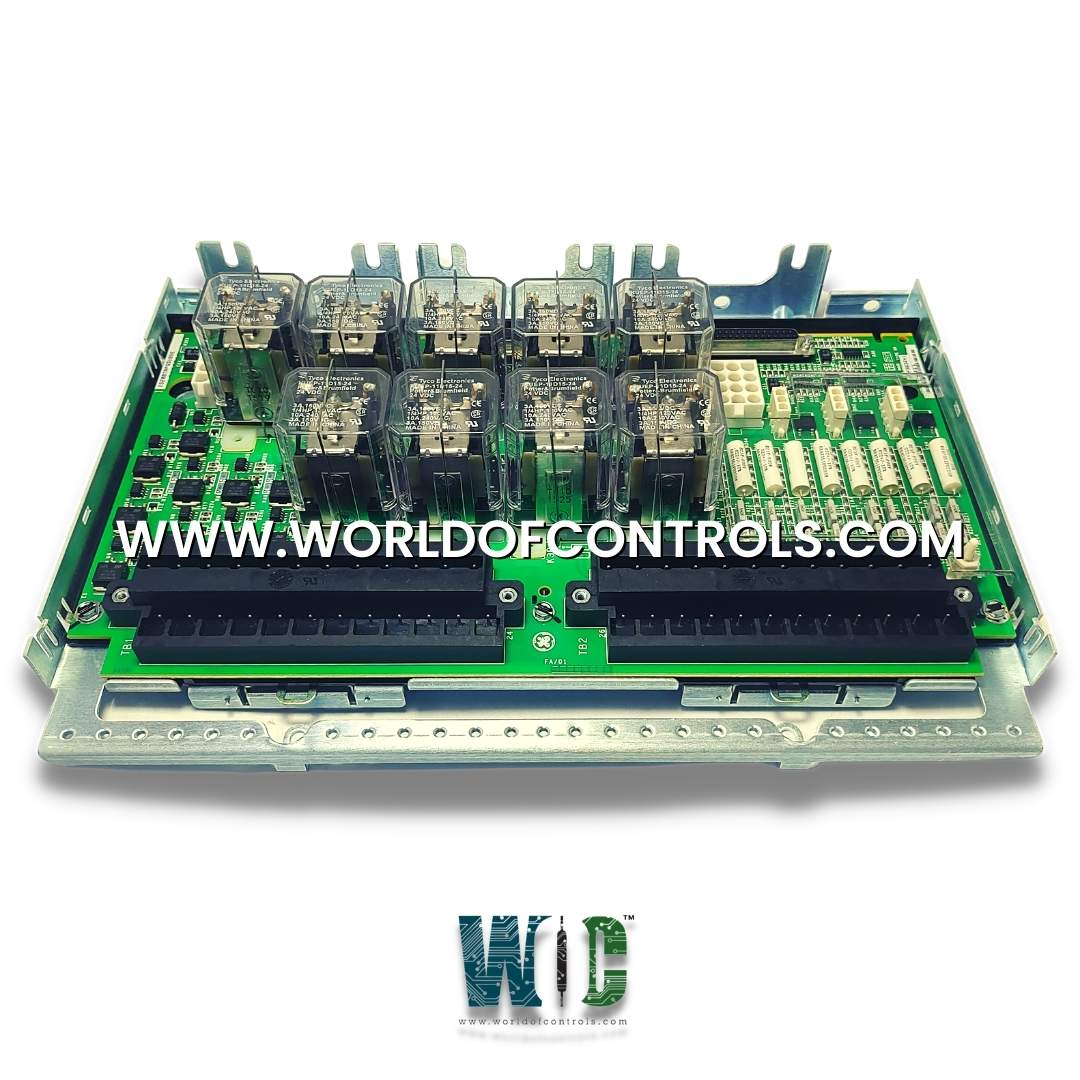

Part Number: IS210TPGSH2B

Manufacturer: General Electric

Series: Mark VI

Product Type: Primary Trip Terminal Board

Repair: 3-5 days

Maximum applied V dc: 145 V

Resistor tolerance: 5 percent

Minimum solenoid impedance: 0 ohm

Availability: In Stock

Country of Manufacturer: United States (USA)

IS210TPGSH2B is a Primary Trip Terminal Board developed by General Electrics. It is a part of Mark VI control system. The board monitors current flow in the relay driver control lines to determine the status of relay coils and includes built-in diagnostics to track supply voltages and verify proper relay operation through normally closed contact monitoring, enhancing system safety and reliability.

WOC has the largest stock of Speedtronic control spares. Please contact our staff by phone or email for pricing and availability on any parts and repairs

What is IS210TPGSH2B?

It is a Primary Trip Terminal Board developed by General Electrics.

Does it support TMR (Triple Modular Redundancy) systems?

Yes, the board supports TMR configurations and uses a two-out-of-three voting logic to ensure accurate and reliable trip decisions across redundant modules.

How does the board detect the status of the trip relays?

It monitors current flow in the relay driver control lines and tracks the relay coil status to determine whether the relay is energized or de-energized.