World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

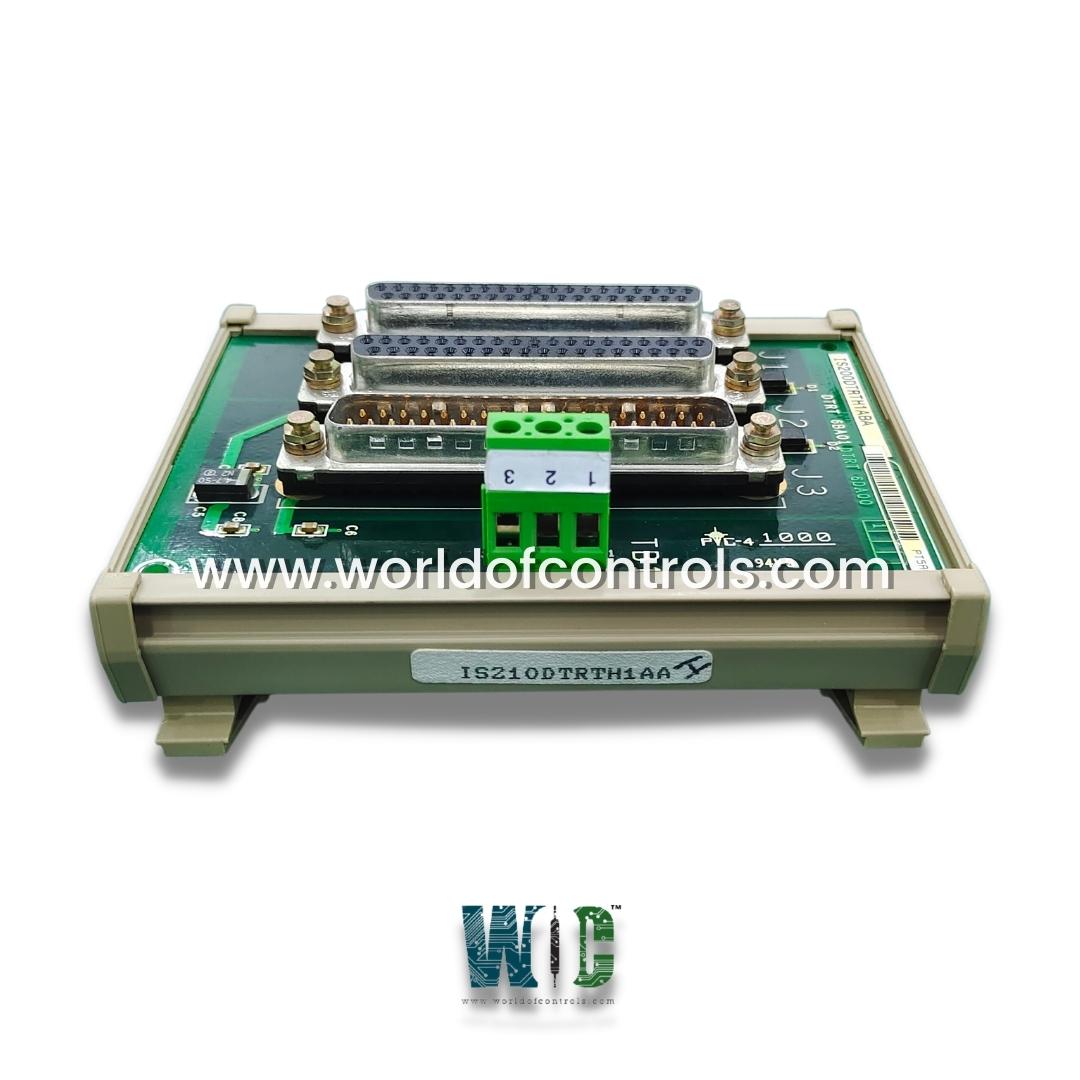

IS210DTRTH1AA - DIN-Rail Mounted Trip Transition Board is available in stock which ships the same day.

IS210DTRTH1AA - DIN-Rail Mounted Trip Transition Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210DTRTH1AA - DIN-Rail Mounted Trip Transition Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IS210DTRTH1AA

Manufacturer: General Electric

Product Type: DIN-Rail Mounted Trip Transition Board

Trip Signal Channels: 6

Connector Type: DC-37

Series: Mark VI

Availability: In Stock

Weight: 2.00 lbs

Operating Temperature Range: -20°C to +70°C

Dimensions: 19.00 x 12.50 x 3.50

Country of Origin: USA

Manual: GEH-6421I

FUNCTIONAL DESCRIPTION:

IS210DTRTH1AA is a DIN-Rail Mounted Trip Transition Board manufactured and designed by General Electric is part of the Mark VI Series used in GE Speedtronic Gas Turbine Control Systems. The DTRT board is a DIN-rail mounted trip transition interface designed to bridge the I/O Controller with the DRLY (Relay Driver) board in industrial control systems. It serves as an alternative to the traditional TRPG board by enabling trip signal transmission in a more modular and flexible format. The DTRT board facilitates three trip functions per I/O controller, supporting up to six relay operations when two controllers are connected simultaneously. This architecture improves system scalability, supports redundancy, and ensures a reliable interface between logic-level outputs and high-power relay actuation required for trip operations.

MECHANICAL MOUNTING AND ELECTRICAL CONNECTIONS:

The DTRT board is designed for secure and convenient installation within industrial control panels using a purpose-built plastic holder that clips directly onto a standard 35 mm DIN rail. This holder ensures a firm mechanical fit and vibration resistance while maintaining compliance with IEC mounting standards. The modular design allows for easy insertion and removal of the board during maintenance or system upgrades without disturbing adjacent components.

The DTRT board interfaces with the I/O controller and the DRLY board via three shielded cables that terminate in a standard DC-37 connector located on the face of the board. This high-density connector streamlines signal routing and ensures proper electrical contact, reducing installation time and minimizing the risk of wiring errors. The trip signals are divided logically: the first three DRLY relay circuits (typically designated as Relay 1 to Relay 3) are driven by the I/O controller connected to port J1, while the second set of three relay circuits (Relay 4 to Relay 6) are controlled via the second I/O controller connected to port J2. This dual-controller configuration enables redundant or segmented control paths, depending on system requirements.

For grounding, the DTRT board includes a Euro-Block terminal strip (TB1), which provides three screw terminals specifically designated for SCOM (signal common or system ground). These ground terminals are internally tied together and must be connected to the I/O controller's signal ground to ensure proper reference levels and prevent floating voltages. To maintain signal integrity and minimize ground loop issues, the SCOM wiring should be as short and direct as possible, ideally terminating at the nearest system ground point or ground bus within the control panel.

APPLICATION REQUIREMENTS AND FUNCTIONAL ROLE OF DTRT:

The DTRT board is a critical component in control system architectures where high-speed trip functionality is essential. It is specifically designed for applications that demand faster trip response times than those achievable through conventional controller-to-DRLY connections alone. In such scenarios, trip signals must be delivered with minimal delay and maximum reliability—requirements that are fulfilled by the combined action of the VTUR (Speed Control Processor), the I/O controller, and the DTRT board acting in conjunction with the DRLY relay output module. This configuration ensures deterministic and rapid trip actuation for high-priority shutdown or protection sequences, such as turbine overspeed or emergency stop conditions.

The DTRT board must be included in system configurations where only a single VTUR controller is present. In these instances, the absence of a secondary VTUR or redundant path makes the DTRT’s role indispensable, as it ensures proper routing and conditioning of trip signals directly to the DRLY board. Omitting the DTRT in such applications would compromise system functionality and potentially violate safety or performance requirements dictated by OEM or industry standards.

This transfer enables the VTUR to verify the presence, identity, and configuration of the connected DRLY board for diagnostic, commissioning, and system integrity verification purposes. Furthermore, the DTRT board includes its unique ID chip, which is internally connected to connector J2. This onboard identification provides additional verification and supports advanced system diagnostics, helping to detect configuration mismatches or connection errors.

WOC offers the industry’s largest inventory of replacement parts for GE Speedtronic Gas Turbine Control Systems. We provide both unused and expertly rebuilt boards, all backed by warranty, along with reliable repair services for damaged components. Whether you're looking for OEM parts or custom automation solutions, our team of experienced professionals is available 24/7 to support your needs. For pricing, availability, or repair inquiries, please don’t hesitate to contact us via phone or email — we're here to assist you with prompt and dependable service.

What is the primary function of the DTRT board?

The DTRT board acts as an interface between the I/O controller and the DRLY relay board. It facilitates the high-speed transmission of trip signals and ensures compatibility with systems that require faster trip response via VTUR, the controller, and DRLY.

What is the recommended method for mounting the DTRT board?

The DTRT board is mounted on a standard 35 mm DIN rail using a snap-in plastic holder. This ensures stability and allows for quick installation or replacement.

What happens if only one controller is connected to the DTRT board?

If only the J1 port is used, the DTRT will control the first three DRLY relays corresponding to that controller. The J2 path remains inactive unless a second controller is connected. However, the ID chip on the DTRT (connected to J2) remains functional for diagnostics, even with a single-controller setup.

How should the SCOM terminals be grounded in a high-noise industrial environment?

For optimal noise suppression, the three SCOM terminals on TB1 should be wired with short, low-resistance cables to a common ground bus or earth ground as close as possible to the controller cabinet. Avoid daisy-chaining with other devices to prevent ground loops.