SPECIFICATIONS

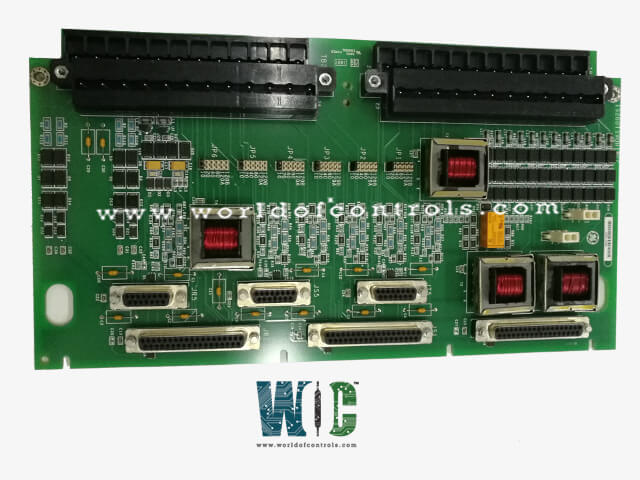

Part No.: IS200TSVOH1BAA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 17.8 cm high x 33.02 cm wide

Technology: Surface mount

Product Type: Servo Terminal Board

Availability: In Stock

Series: Mark VI

Functional Description

IS200TSVOH1BAA is a Servo Terminal Board developed by GE. It is a part of the Mark VI control system. The Servo Terminal Board (TSVO) controls the electro-hydraulic servo valves, which are responsible for actuating the steam and fuel valves in turbine systems. These servo valves modulate the flow of steam or fuel, which in turn controls the turbine's power output and operational efficiency.

Features

- The valve positions are precisely measured using Linear Variable Differential Transformers (LVDTs), which provide real-time feedback on the valve's position. This feedback is essential for maintaining accurate control of the turbine system.

- Two cables are connected from the TSVO to the I/O processor (VSVO), facilitating communication between these components. The J5 plug on the front of the VSVO and the J3/4 connectors on the VME rack are used to establish these connections.

- The TSVO also distributes signals in two modes: Simplex and Triple Modular Redundancy (TMR). Simplex signals are provided through the JR1 connector, while TMR signals are distributed to the JR1, JS1, and JT1 connectors. TMR adds a layer of fault tolerance and reliability by utilizing three parallel systems that compare results to detect and correct errors.

- Additionally, the TSVO includes external trip capability through connectors JD1 or JD2, which are linked to a protection module. This trip feature ensures safety by allowing the system to shut down in response to critical protection signals, preventing potential damage to the turbine and associated systems.

Installation

- The installation process for sensors and servo valves involves direct wiring to two I/O terminal blocks that are securely mounted on the Servo Terminal Board (TSVO). These terminal blocks serve as the connection point for various components in the control system, ensuring proper communication and functionality.

- Each terminal block is fastened with two screws for stability and includes 24 individual terminals. These terminals are designed to accept wiring up to #12 AWG (American Wire Gauge), making them capable of handling the required current and ensuring a secure, reliable connection.

- In addition to the terminal blocks, there is a shield termination strip located to the left of each block. This strip is connected to the chassis ground, providing electromagnetic interference (EMI) protection by grounding the shielded cables. This is a critical step to ensure the integrity of the signals being transmitted by minimizing noise and interference that could potentially affect the performance of the sensors or servo valves.

- For external safety or trip mechanisms, wiring is plugged into either JD1 or JD2 connectors. These connectors are essential for linking the external trip circuitry, which triggers the system's shutdown procedures when necessary, protecting the turbine and associated machinery from potential damage in case of malfunctions or critical errors.

- In a Triple Modular Redundancy (TMR) configuration, each servo output can control up to three separate coils. This configuration provides increased fault tolerance and system reliability, as the three coils operate independently but in parallel. If one coil fails, the other two can continue operating, ensuring continuous system function.

- The current supplied to each coil is controlled through jumpers, JP1-6, located on the terminal board. These jumpers allow for the selection and adjustment of the current output for each coil. By configuring these jumpers appropriately, the system can be optimized for the specific requirements of the connected servo valves, ensuring accurate and stable control of the turbine system.

�

Configuration

- The configuration of the Servo Terminal Board (TSVO) depends on whether the system is set up in Simplex or Triple Modular Redundancy (TMR) mode, allowing for flexibility based on the system's reliability and redundancy requirements.

- Simplex System Configuration: In a simplex setup, where each servo operates with a single coil, the configuration is straightforward:

- Servo 1 is configured using jumper JP1 to select the appropriate coil current, ensuring the servo valve operates within its specified range.

- Servo 2 is similarly configured using jumper JP4.

- These jumpers are adjusted according to the specifications detailed in the Servo Coil Ratings table, which provides the necessary current values to ensure optimal performance for each coil. Correct jumper configuration is crucial, as it determines the current delivered to the servo coils, affecting the accuracy and responsiveness of the servo valves.

- TMR System Configuration: In a Triple Modular Redundancy (TMR) system, each servo output is connected to three coils, providing enhanced fault tolerance by comparing the outputs of three independent coils to detect and correct potential errors. In this case:

- For Servo 1, the current to each of the three coils is selected using jumpers JP1, JP2, and JP3.

- For Servo 2, the current for its three coils is configured using jumpers JP4, JP5, and JP6.

- Each jumper is adjusted to match the correct coil current, ensuring that all three coils are properly calibrated and balanced for optimal performance. This triple-coil configuration enhances system reliability by ensuring continuous operation even in the event of a coil failure.

- Additional Configuration: Apart from the physical jumper settings on the board, all other configuration of the servo board is performed through the system�s toolbox software. The toolbox allows for more detailed system adjustments, fine-tuning, and diagnostic checks to ensure the servo system is configured accurately and operates efficiently. This software-based configuration provides flexibility for system calibration and monitoring beyond the physical hardware adjustments.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TSVOH1BAA?

It is a Servo Terminal Board developed by GE under the Mark VI series.

What is the maximum two-way cable resistance allowed?

The maximum allowable two-way cable resistance is 15 ohms. Ensuring the cable resistance remains within this limit is critical for maintaining proper operation and signal integrity.

What types of current sources are available for the servo coils?

Since there are many different types of servo coils, the system provides a variety of bi-directional current sources, which are jumper selectable. This flexibility allows for compatibility with a wide range of servo coil types, enabling customization based on the specific servo system in use.

Why are bi-directional current sources important for servo coils?

Bi-directional current sources are essential for controlling the movement of the servo valves in both directions (open/close or increase/decrease). These current sources ensure that the system can accurately control the valve position, regardless of the direction of motion required.