World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200STCIH6ADD - Contact Input Terminal Board is available in stock which ships the same day.

IS200STCIH6ADD - Contact Input Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200STCIH6ADD - Contact Input Terminal Board, contact us and we will get back to you within 24 hours.

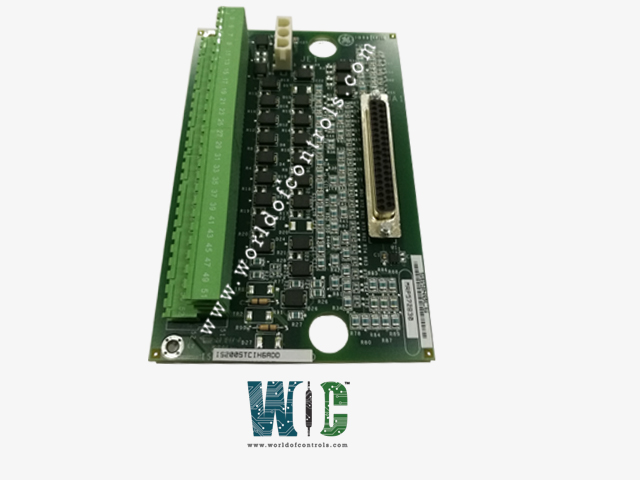

Part No.: IS200STCIH6ADD

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 15.9 cm high x 10.2 cm wide

Temperature: -30 to + 65oC

Technology: Surface-mount

Product Type: contact input terminal board

Availability: In Stock

Series: Mark VIe

IS200STCIH6ADD is a contact input terminal board developed by GE. It is a part of Mark VIe control system. The component accommodate contact inputs and integrate seamlessly within a DIN-rail or flat mounting configuration. Its design and functionality cater to industrial environments and systems, offering a compact and versatile solution for handling a myriad of input signals. The board represents a sophisticated yet user-friendly interface solution within industrial control systems, offering a compact and reliable platform for accepting contact inputs while ensuring compatibility, protection against electrical disturbances, and seamless integration with the Mark VIe system. Its functionality contributes significantly to the system's ability to accurately capture and utilize contact-based input signals, thereby enhancing overall control and monitoring capabilities within industrial settings.

The installation process involves several key steps and considerations to ensure proper mounting, wiring, and functionality within the control system. The STCI, along with a plastic insulator, is mounted on a sheet metal carrier, which can then be affixed onto a DIN rail. Alternatively, there is an option to mount the plus insulator on a sheet metal assembly, which is then securely bolted into a cabinet.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

What is IS200STCIH6ADD?

It is a contact input terminal board developed by GE under the Mark VIe series.

What functions does the I/O processor monitor on the STCI?

The I/O processor oversees several critical functions, including monitoring the contact excitation voltage, conducting diagnostic tests on inputs, and interrogating the terminal board connector's ID device.

Can the I/O processor perform diagnostic tests on the inputs associated with the terminal board?

Yes, as part of a diagnostic test, the I/O processor conducts a comprehensive check by forcing all inputs associated with the terminal board into the open contact state. Any input that fails this diagnostic test is automatically forced into the failsafe state (open contact), and a fault is generated, highlighting the failed input.