World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200TRLYS2F - Relay Output Board is available in stock which ships the same day.

IS200TRLYS2F - Relay Output Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TRLYS2F - Relay Output Board, contact us and we will get back to you within 24 hours.

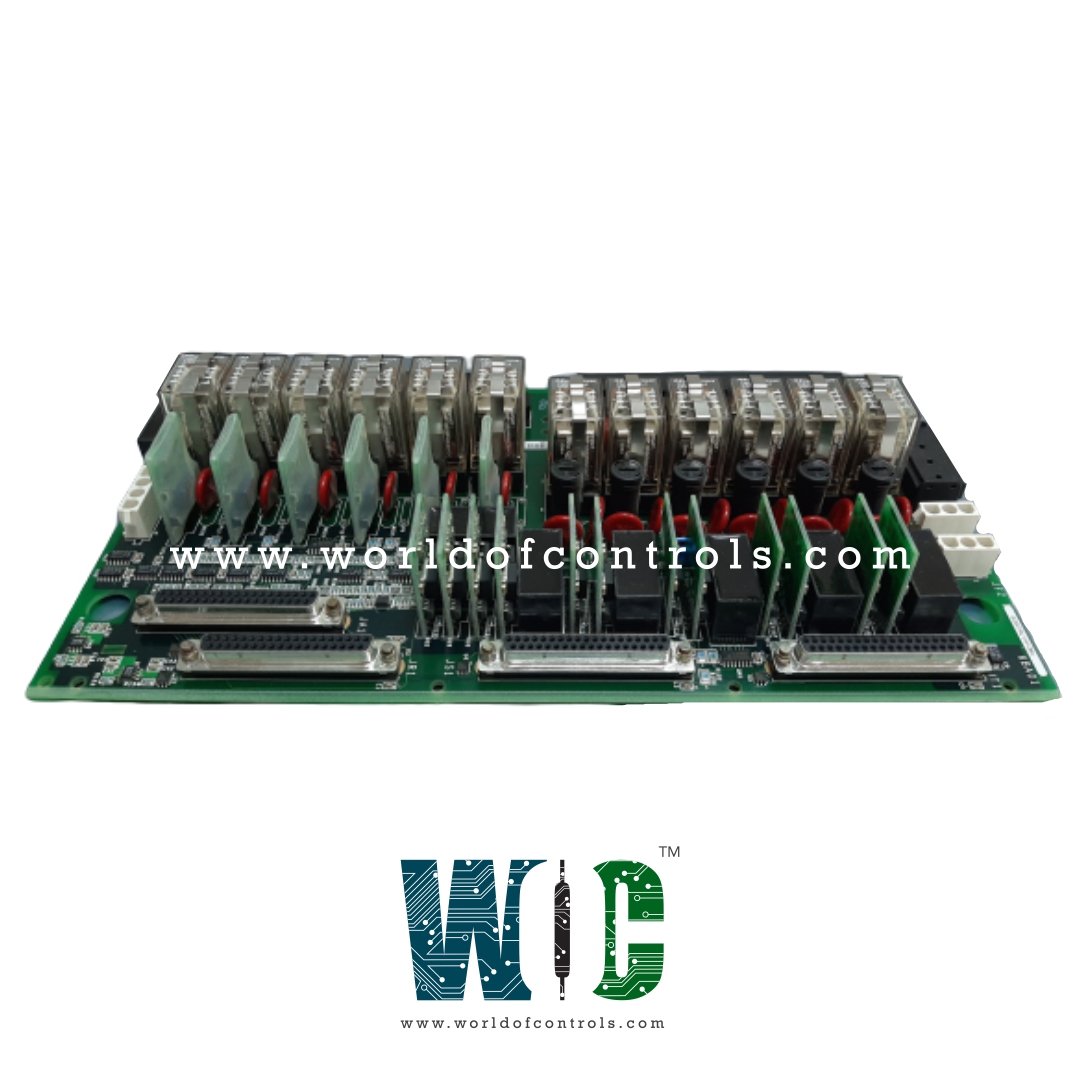

Part No.: IS200TRLYS2F

Manufacturer: General Electric

Manual: GEH-6721D

Maximum inrush current: 10A

Contact material: Silver cad-oxide

Size: 17.8 cm wide x 33.02 cm, high

Size 17.8 cm wide x 33.02 cm high

Temperature -30 to + 65oC

Availability: In Stock

Country of Manufacture: United States (USA)

IS200TRLYS2F is a Turbine Relay Output Board developed by GE. It is a part of Mark VIeS control system. It is a specialized interface card designed to work with a VCCC or VCRC Discrete I/O board. It operates on a voltage range of 120 VAC and 28/125 VDC, making it suitable for various industrial applications. This card is typically used in conjunction with a WPDF daughterboard, enhancing its capabilities. The relay terminal board features jumpers labeled JP1 through JP12. To enable contact voltage sensing for specific relays, users can insert jumpers as needed. This allows for customized configuration based on the relay requirements and application. Additionally, the terminal board is equipped with fuses labeled FU1 through FU12. When power is required for relays 1-6, it is essential to place two fuses in each power circuit that supplies those specific relays. For instance, FU1 and FU7 together supply power to relay output 1. Users can refer to the terminal board wiring diagram to ensure correct and precise wiring connections. Proper fuse placement ensures protection and efficient operation of the relay outputs, enhancing the overall reliability of the system.

World of Controls has the most comprehensive collection of GE Mark VIeS components. Please contact WOC as soon as possible if you require any extra information.

What is IS200TRLYS2F?

It is a Turbine Relay Output Board developed by GE

What are the relay configuration options and how can contact voltage sensing be enabled for specific relays?

The relay terminal board features jumpers labeled JP1 through JP12. Users can utilize these jumpers to enable contact voltage sensing for specific relays based on their application requirements. This allows for customized configuration and precise control over the relay functions.

What is the significance of the fuses labeled FU1 through FU12 on the board?

The terminal board is equipped with fuses labeled FU1 through FU12. When power is required for relays 1-6, it is essential to place two fuses in each power circuit supplying those specific relays. For example, FU1 and FU7 together supply power to relay output 1. Proper fuse placement ensures protection and efficient operation of the relay outputs, contributing to the overall reliability of the system.

Can you explain the type of relays available and their control mechanism?

It features 12 fused solenoid driver relays equipped with WPDF, and an additional 12 dry circuit relays without WPDF. These relays are mechanical Form B type with TMR (Triple Modular Redundant) control, ensuring a reliable and redundant operation, making them well-suited for critical functions in the system.