SPECIFICATIONS

Part No.: IS200TREGS5B

Manufacturer: General Electric

Product Manual: GEH-6721D

Trip interlock isolation: Optical isolation to 1500 V on all inputs

Trip interlock filter: Hardware filter, 4 ms

Trip interlock AC voltage rejection: 60 V rms

Size: 17.8 cm wide x 33.02 cm, high

Solenoid inductance: 0.1 s

Suppression: MOV across the solenoid

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

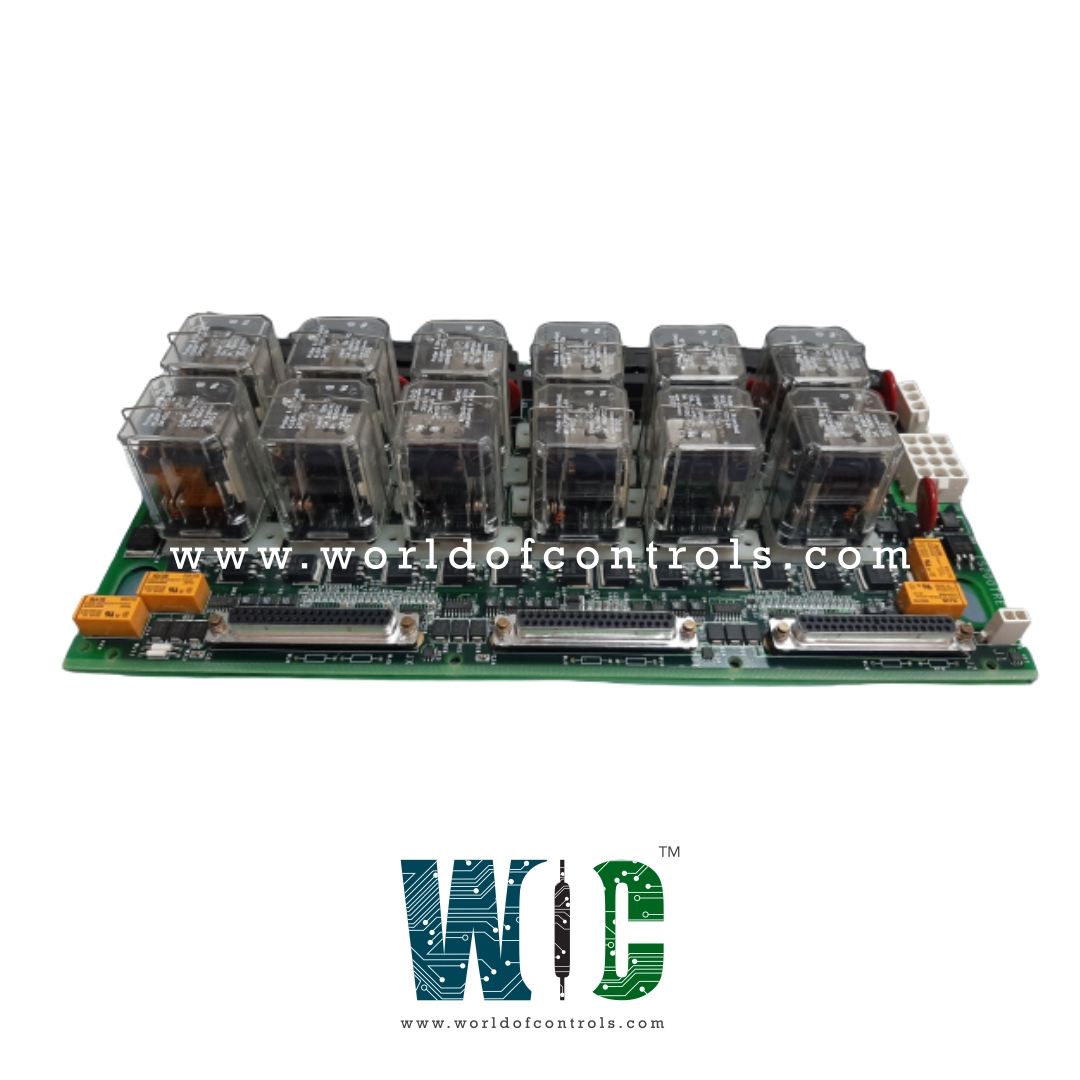

IS200TREGS5B is a Turbine Emergency Trip terminal board developed by GE. It is a part of Mark VIe control system. The Gas Turbine Emergency Trip (TREG) terminal board provides power and control for emergency trip solenoids in a gas turbine system. Its functionality is closely integrated with the I/O controller, ensuring reliable and timely emergency responses when necessary. The Gas Turbine Emergency Trip terminal board, in conjunction with the board and the I/O controller, ensures the proper and reliable operation of emergency trip solenoids in a gas turbine system. By providing power to the solenoids, enabling daisy chain connections, and implementing voting logic for control, the TREG board contributes to the overall safety and protection of the gas turbine during critical situations. The I/O controller's central role in monitoring turbine speed and overseeing emergency functions ensures timely and precise responses, safeguarding the turbine and minimizing potential risks during emergency scenarios.

Features

- Powering Emergency Trip Solenoids: The primary function of the terminal board is to supply power to three emergency trip solenoids. These solenoids are crucial components responsible for executing emergency trips to shut down the gas turbine in critical situations. The TREG board ensures the efficient and reliable delivery of the positive side of DC power to these solenoids.

- Daisy Chain Connection of Trip Solenoids: The TREG board supports up to three emergency trip solenoids, and it can be connected in a daisy chain fashion. This connection configuration enables multiple trip solenoids to be seamlessly integrated and controlled within the gas turbine system.

- TRPG Terminal Board - Negative Side Power Provider: The terminal board complements by providing the negative side of the DC power required for the emergency trip solenoids. Together, the TREG and TRPG boards ensure a complete power supply to the solenoids, enabling their efficient operation during emergencies.

- I/O Controller - Central Control and Protection: The I/O controller acts as the central control unit for the gas turbine system and plays a crucial role in safeguarding the turbine during emergencies. It is responsible for emergency overspeed protection, which monitors the turbine's rotational speed and initiates a trip if the speed exceeds the safe limits. Additionally, the I/O controller handles emergency stop functions, allowing for immediate turbine shutdown when necessary.

- Voting Logic for Trip Solenoids: Equipped with 12 relays, with nine of these relays forming three groups of three to implement a voting system. This voting logic allows the I/O controller to control the three trip solenoids effectively. The I/O controller assesses inputs and makes decisions based on the voting results to trigger the appropriate solenoids in response to specific emergency conditions.

Operation

- Operates in close coordination with the VPRO protection module, ensuring robust and reliable control over emergency trip functions. The TREG board is designed to be fully controlled by the module, establishing a seamless interface for critical system operations.

- VPRO - The Central Control Module: The protection module assumes the pivotal role of being the central control module. It handles all aspects of emergency trip control, ensuring that the gas turbine system promptly responds to potential hazards. The VPRO module utilizes its intelligence to process various sensor inputs and make real-time decisions regarding emergency trip actions.

- Control Connections - J2 Power Cable and Trip Solenoids: The board establishes essential control connections with the VPRO module. The J2 power cable serves as the main communication link between the VPRO module and the board, enabling data exchange, command transmission, and system status monitoring. Through this connection, the VPRO module effectively controls, regulates the power supply to the trip solenoids and other essential functions.

- The trip solenoids serve as another crucial control element. The VPRO module communicates with the board to activate or deactivate these solenoids based on the turbine's operating conditions. In emergency scenarios, the VPRO module commands the trip solenoids to execute immediate shutdowns, ensuring the safety of the gas turbine and the surrounding equipment.

- Additional Cable in Simplex Systems - TSVO Terminal Board: In simplex systems, an additional cable is used to carry a trip signal from J1 to the terminal board. This trip signal serves an important function by providing a servo valve clamp action upon turbine trip. The servo valve is a crucial component that controls the flow of fluids in the turbine system, and the clamp function ensures its immediate closure during an emergency trip, further enhancing the safety and protection of the gas turbine.

- The integration of the board with the VPRO protection module and its control connections via the J2 power cable and trip solenoids exemplifies a highly efficient and reliable emergency trip system. In simplex systems, the inclusion of the TSVO terminal board with the trip signal cable ensures swift and precise servo valve closure, adding an extra layer of safety to the overall gas turbine system.

- Through this seamless coordination and intelligent control, the TREG board, in conjunction with the VPRO protection module and other connected components, plays a pivotal role in ensuring the smooth and safe operation of gas turbines.

World of Controls has the most comprehensive collection of GE Mark VIe components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS200TREGS5B?

It is a Turbine Emergency Trip terminal board developed by GE

How does the Turbine Emergency Trip Terminal Board contribute to the safety of the gas turbine system?

The primary function of the Turbine Emergency Trip Terminal Board is to supply power to three emergency trip solenoids. These solenoids play a critical role in executing emergency trips to promptly shut down the gas turbine during potentially hazardous situations. By ensuring efficient delivery of positive DC power to the solenoids, the TREG board enhances the overall safety and protection of the gas turbine.

How does the board facilitate the connection of multiple trip solenoids?

The Turbine Emergency Trip Terminal Board supports up to three emergency trip solenoids and can be connected in a daisy chain configuration. This connection setup allows multiple trip solenoids to be seamlessly integrated and controlled within the gas turbine system, streamlining their operation and ensuring quick response times during emergencies.

What is the role of the TRPG Terminal Board in conjunction with the board?

The Board complements by providing the negative side of the DC power required for the emergency trip solenoids. Together, the TREG and TRPG boards ensure a complete and balanced power supply to the solenoids, contributing to their efficient operation during emergency scenarios.