World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

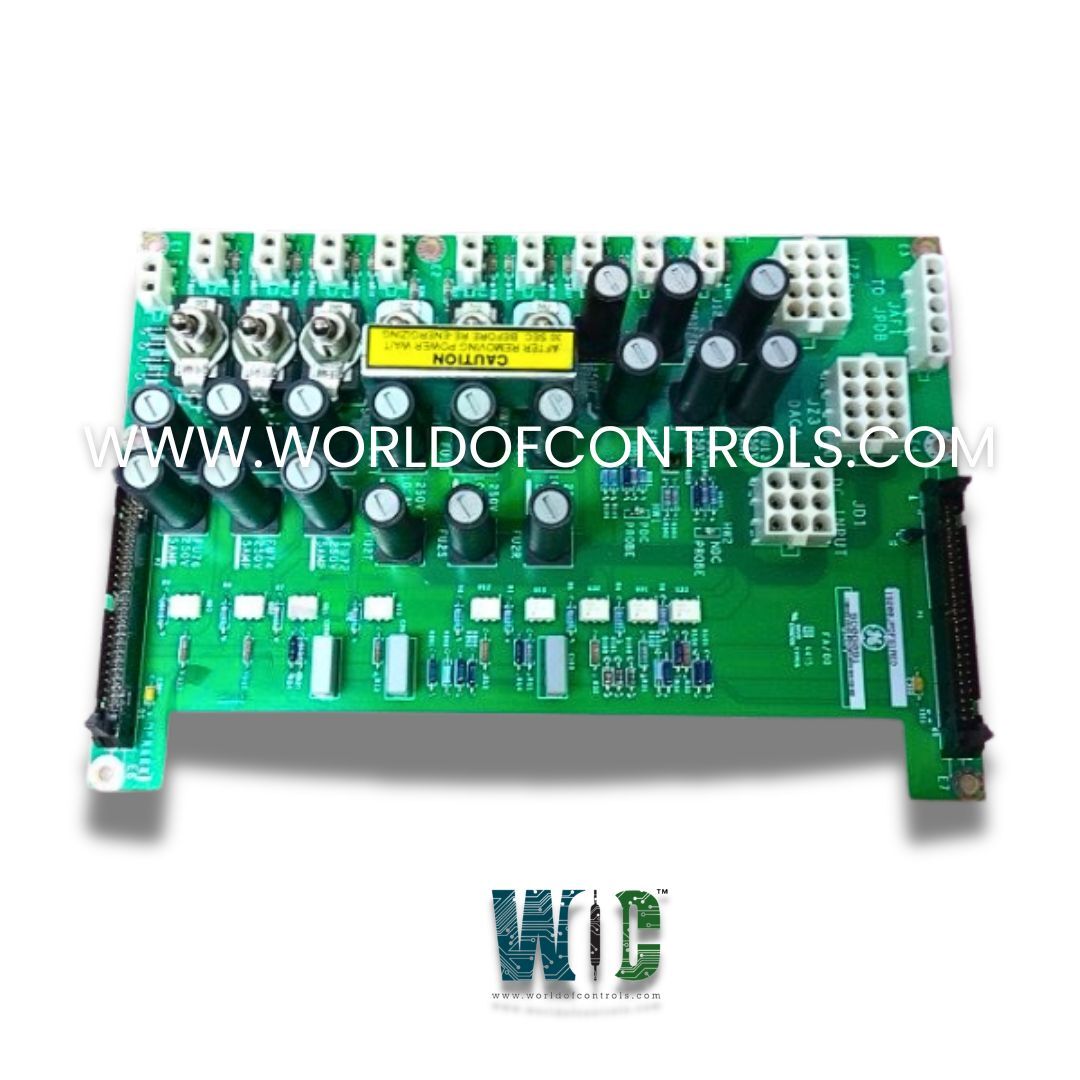

IS200JPDFG1ACA - DC Power Distribution Module is available in stock which ships the same day.

IS200JPDFG1ACA - DC Power Distribution Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200JPDFG1ACA - DC Power Distribution Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200JPDFG1ACA

Manufacturer: General Electric

Series: Mark VIe

Board rating: 125 V DC

Product Type: DC Power Distribution Module

Impedance to the ground: 75 Ohms

Power Requirements: +5 V dc, 6 A

Operating temperature: -30 to +65�C

Size: 30.48cm High x 21.33cm

Mounting: 4 mounting Holes

Repair: 3-7 days

Fuse for connectors J1R, J1S, J1T: 10 A 250 V

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS200JPDFG1ACA is a DC Power Distribution Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The 125 V DC power distribution module IS200JPDF accepts redundant 125 V dc power inputs and distributes power to other system boards. JPDF works with a floating dc bus that is centered on Earth rather than with a grounded system. This permits detecting a system ground fault and carries a non-hazardous live 125 V dc rating. Input 125 V dc battery power is connected to a terminal board on the IS2020JPDF module. The power is then routed through a 125 V dc 30 A circuit breaker and line filter before being connected to the IS200JPDF board through the J1 connector. Dc voltage is then routed to three fused, non-switched outputs and six fused, switched outputs. Ac power is routed through the board to the DACA modules, which are converted to dc power. Dc power returns to JPDF, combined with the battery power input. JPDF can operate with any combination of one or more inputs, creating a high-reliability source of 125 V dc power for the control system. The IS200JPDF module provides full status feedback using a connection to a PPDA I/O pack. Feedback includes bus magnitude, ground fault detection, and detection of excessive ac voltage on the DC bus. Each fused branch circuit is monitored to indicate the presence of output power.

FLOATING DC BUS DESIGN

Unlike conventional grounded systems, the IS200JPDF operates with a floating DC bus that is centered on Earth ground rather than being directly grounded. This design choice provides several operational advantages:

POWER INPUT AND CONDITIONING:

POWER DISTRIBUTION OUTPUTS:

INSTALLATION:

The IS200JPDF module is base-mounted vertically on a metal base located inside the PDM cabinet. For safety and grounding purposes, it is essential to establish a proper connection between the JPDF sheet metal and the system�s protective earth (PE). The input battery power is supplied to the module via the DCHI (positive) and DCLO (negative) terminals. When the system includes one or two DACA modules, AC power is typically supplied through connector JAF1, often sourced from an IS2020JPDB module. The DACA modules connect to the JPDF board using connectors JZ2 and JZ3, facilitating the flow of AC power, which is then converted to DC and reintegrated into the power system.

In setups utilizing a PPDA power diagnostic I/O pack, a 50-pin ribbon cable is required to connect the P1 connector on the JPDF module to the P2 connector on the board that houses the PPDA. This ribbon cable enables the communication of diagnostic and power monitoring signals. If needed, this connection can be extended through other core PDM boards using additional P2 connectors, maintaining a unified power distribution and diagnostics chain across the system.

OPERATION:

The IS200JPDF module receives its primary DC battery power through the DCHI and DCLO terminals, which are then routed through a 30 A DC circuit breaker for overcurrent protection. From there, the power enters a filter assembly located beneath the circuit board to eliminate electrical noise and transients. The filtered DC output passes through a series diode, preventing reverse current flow, before being delivered to the internal circuitry of the JPDF board for distribution to connected system components.

The module also supports AC power input via the JAF1 connector, typically receiving 115/230 V AC. This AC power is routed to connectors JZ2 and JZ3, which connect to DACA modules responsible for converting AC to 125 V DC. The DC output from the DACAs is returned to the JPDF module through the same connectors and is combined with the battery power, if available. This configuration ensures a redundant and reliable power source, maintaining a consistent 125 V DC output to support the turbine control system even in the event of a single power source failure.

GROUNDING:

Mark VIe systems divide the ground into a protective earth (PE) and a functional earth (FE). The PE ground must be connected to an appropriate earth connection by all local standards. The minimum grounding must be capable of carrying 60 A for 60 seconds with no more than a 10-volt drop. The FE ground system must be bonded to the PE ground system at one point. The JPDF is grounded through metal mounting supports fastened to the underlying sheet metal of a metal module. The ground is applied to the metal switch bodies on JPDF. Additionally, the ground is used as a local reference point when creating the feedback signals appearing on P2. The sheet metal of the module is insulated to the surface upon which it is mounted. This is done specifically to allow the definition of the JPDF ground independent of the mounting surface. Typically, JPDF is mounted to a base grounded to FE. JPDF would be located low in the cabinet, and a separate ground wire from the JPDF module would be provided to PE. The minimum length of the ground wire is important to keep impedance low at radio frequencies, allowing the input line filters to function properly.

WOC maintains the largest inventory of OEM replacement parts for GE Distributed Control Systems. We also offer comprehensive repair services for faulty boards, along with the supply of unused and refurbished boards, all backed by a warranty. Our experienced technical team is available 24/7 to support your OEM requirements and provide expert assistance with any automation needs. For inquiries regarding pricing and availability of parts or repair services, please contact us via phone or email.

What are the primary power input sources for the module?

The module accepts redundant 125 V DC inputs typically sourced from battery banks. These inputs are applied to terminals DCHI (positive) and DCLO (negative). Additionally, the module can receive 115/230 V AC power through connector JAF1, which is routed to external DACA modules. The DACA units then convert the AC to DC and feed it back into the module, providing a dual-source input structure that enhances reliability.

How is the input power conditioned before distribution?

DC power first passes through a 30 A circuit breaker, offering protection against overloads and short circuits. The power then flows into a filter assembly located beneath the circuit board, which eliminates electrical noise and voltage spikes. After filtering, it passes through a series of diodes that prevent reverse current flow, protecting the board and connected systems from potential damage due to power backfeed.

How is AC power integrated into the module's operation?

When AC input is used, it is applied via the JAF1 connector and routed internally to connectors JZ2 and JZ3, which interface with DACA modules. These modules convert the AC input into 125 V DC. The resulting DC output is returned to the PDM through the same JZ2 and JZ3 connectors. This DC is then combined with any battery-sourced DC power to create a robust, redundant power supply.