World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200IIDAG1A - Direct Current Innovation Board is available in stock which ships the same day.

IS200IIDAG1A - Direct Current Innovation Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200IIDAG1A - Direct Current Innovation Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

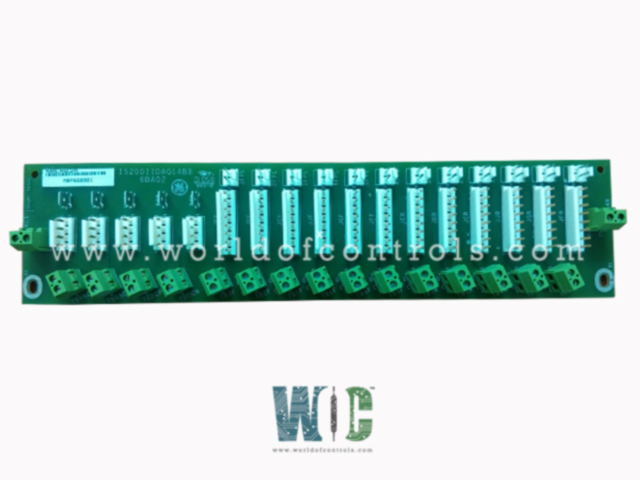

Part Number: IS200IIDAG1A

Manufacturer: General Electric

Series: EX2100

Product Type: Direct Current Innovation Board

Number of Input channels: 24

Power supply voltage: 28V DC

Technology: Surface Mount

Operating temperature: -30 to 65 °C

Size: 33.02 cm high x 17.8 cm

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS200IIDAG1A is a Direct Current Innovation Board manufactured and designed by General Electric as part of the EX2100 Series used in GE Excitation Control Systems. The Direct Current (DC) Innovation Board is a cutting-edge interface and control module designed to manage and regulate DC electrical systems within industrial or specialized environments. Its core function is to monitor voltage levels, current flow, and load distribution across connected DC circuits, ensuring efficient energy usage and system reliability. The board may incorporate smart features such as programmable logic, real-time data analytics, and support for energy storage or renewable inputs, making it suitable for advanced energy management applications.

In terms of connectivity, the board supports widely used communication protocols like CANopen, Modbus, EtherCAT, and RS485, offering flexibility for system integration. It includes multiple digital and analog inputs and outputs, facilitating easy interaction with sensors and other peripheral devices. Motor control is achieved through Pulse Width Modulation (PWM) technology, which ensures smooth speed regulation and accurate torque control, while real-time feedback from encoders and tachometers ensures optimal motor performance.

INSTALLATION:

The DC Innovation Board is typically carried out within a control cabinet or protected electrical enclosure, using DIN rail or panel mounting, depending on the model. The unit includes marked terminal blocks for power inputs, load monitoring, and communication interfaces. It must be installed in compliance with relevant electrical standards, ensuring all connections are made with the power supply turned off to prevent any electrical hazard. Proper cable routing, shielding for analog lines, and grounding practices must be observed to reduce electromagnetic interference and maintain system integrity. The board operates reliably in industrial temperature and humidity ranges and is designed for environments where space and noise immunity are critical.

OPERATION:

The board performs continuous real-time monitoring of DC voltage and current across connected sources and loads. It processes input signals through onboard signal conditioning circuits and transmits the data to external control systems using supported protocols such as Modbus RTU or CANopen. The board can also execute embedded logic functions including voltage regulation, current limiting, undervoltage cut-off, and fault isolation. It ensures system stability by providing consistent feedback and control signals, supporting both standalone operation and integration into broader energy or automation systems. The design supports rapid data refresh rates, precise fault detection, and control synchronization with other subsystems.

COMPATIBILITY:

The DC Innovation Board is compatible with a wide range of DC systems, including solar photovoltaic arrays, battery storage modules, DC motor drives, industrial UPS systems, and telecom power plants. It supports standard industrial voltages such as 12V, 24V, 48V, and higher ranges up to 600VDC, depending on model configuration. Communication with supervisory systems is enabled via industry-standard protocols like Modbus RTU, CAN, and optionally Ethernet/IP, allowing seamless integration with equipment from leading manufacturers such as Siemens, Schneider, GE, and Rockwell Automation. The board complies with CE and RoHS standards, ensuring safe operation and regulatory conformity in global industrial applications.

WOC maintains the largest inventory of OEM replacement parts for GE Excitation and Turbine Control Systems. In addition to supplying genuine components, we offer expert repair services for faulty boards and provide both unused and refurbished units, each backed by a warranty. Our experienced team is available 24/7 to support your OEM part requirements and automation challenges. For pricing, availability, or assistance with parts and repairs, please contact us via phone or email—we’re here to help.

What types of motors can the DC Innovation Board control?

The DC Innovation Board can control standard DC motors, including brushed and brushless motors. It is compatible with a wide range of DC motor types, including permanent magnet (PM) motors, stepper motors, and other motor technologies that operate on DC power.

What communication protocols are supported?

The board supports industrial communication protocols such as Modbus RTU (via RS-485), CANopen, and optionally Ethernet/IP or Modbus TCP, depending on the model. These enable seamless integration with modern control systems.

What voltage levels does the board support?

Depending on the specific model, the board typically supports standard industrial DC voltage ranges including 12VDC, 24VDC, 48VDC, and up to 600VDC. Always refer to the datasheet for the exact supported range.