World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200GGXIG1A - Expander Load Source Board is available in stock which ships the same day.

IS200GGXIG1A - Expander Load Source Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200GGXIG1A - Expander Load Source Board, contact us and we will get back to you within 24 hours.

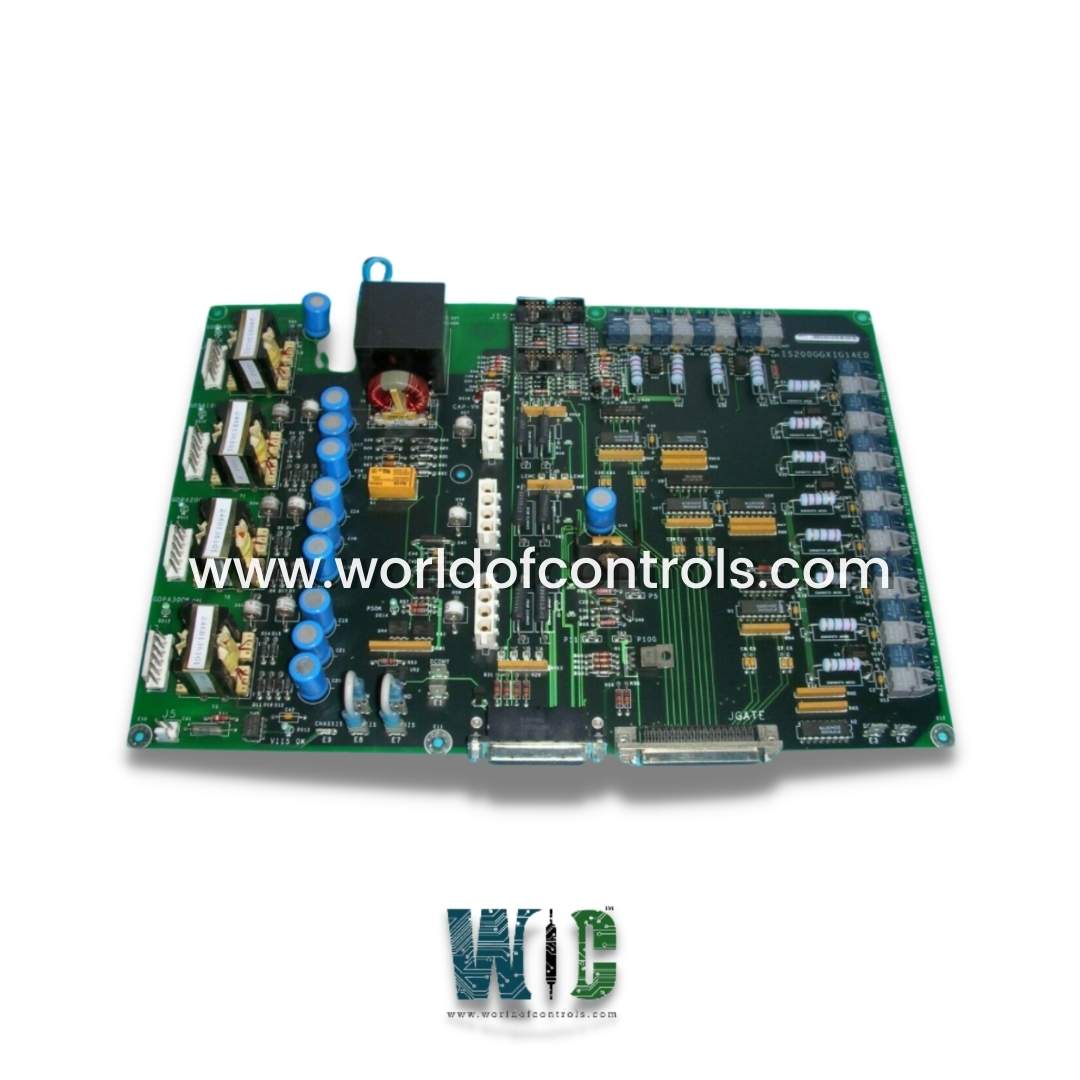

Part Number: IS200GGXIG1A

Manufacturer: General Electric

Series: Mark VI

Product type: Expander Load Source Board

Availability: In Stock

Country of Manufacture: United States (USA)

IS200GGXIG1A is an expander load source board designed and developed by GE. It is a part of GE Mark VI control system. This board plays a critical role in controlling and isolating the high-voltage power bridge from other components within the system. It ensures smooth coordination between the IGCT (Integrated Gate-Commutated Thyristor) switching devices and associated control cards by converting RS422 electrical signals into fiber-optic signals, which are used to gate and manage the bridge’s switching operation. As a key part of GE’s Innovation Series, drives and turbine control systems enables efficient power management, signal integrity, and fault isolation, supporting the overall safety and performance of the Mark VI control architecture.

Due to the presence of high surface voltages, they must be installed and handled with strict adherence to GE’s recommended safety procedures. Improper handling may lead to equipment damage or electrical hazards. The following key precautions must be followed:

Within the GE Mark VI control environment, it acts as a communication and control hub between the high-power sections and logic-level control boards. By handling the electrical-to-optical signal conversion and managing isolation between circuits, it ensures:

WOC is happy to assist you with any of your automation requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IS200GGXIG1A?

It is an expander load source designed and developed by GE.

How does the Expander Load Source card communicate with other boards?

The board uses several connectors for communication and power management. JFBK connects to the BICI board. JGATE connects to the BPII board. J5 monitors control power for the GDPA board. It also uses fiber-optic connectors for communication with the IGCT switching devices.

Does the Board have any adjustable components or fuses?

No. The board does not include adjustable hardware devices or fuses. This design minimizes user intervention and reduces calibration needs.

What diagnostic features are available on the board?

The Board includes test points (TPs) for voltage and signal monitoring, and LED indicators for operational status and fault detection, enabling efficient troubleshooting.