SPECIFICATIONS

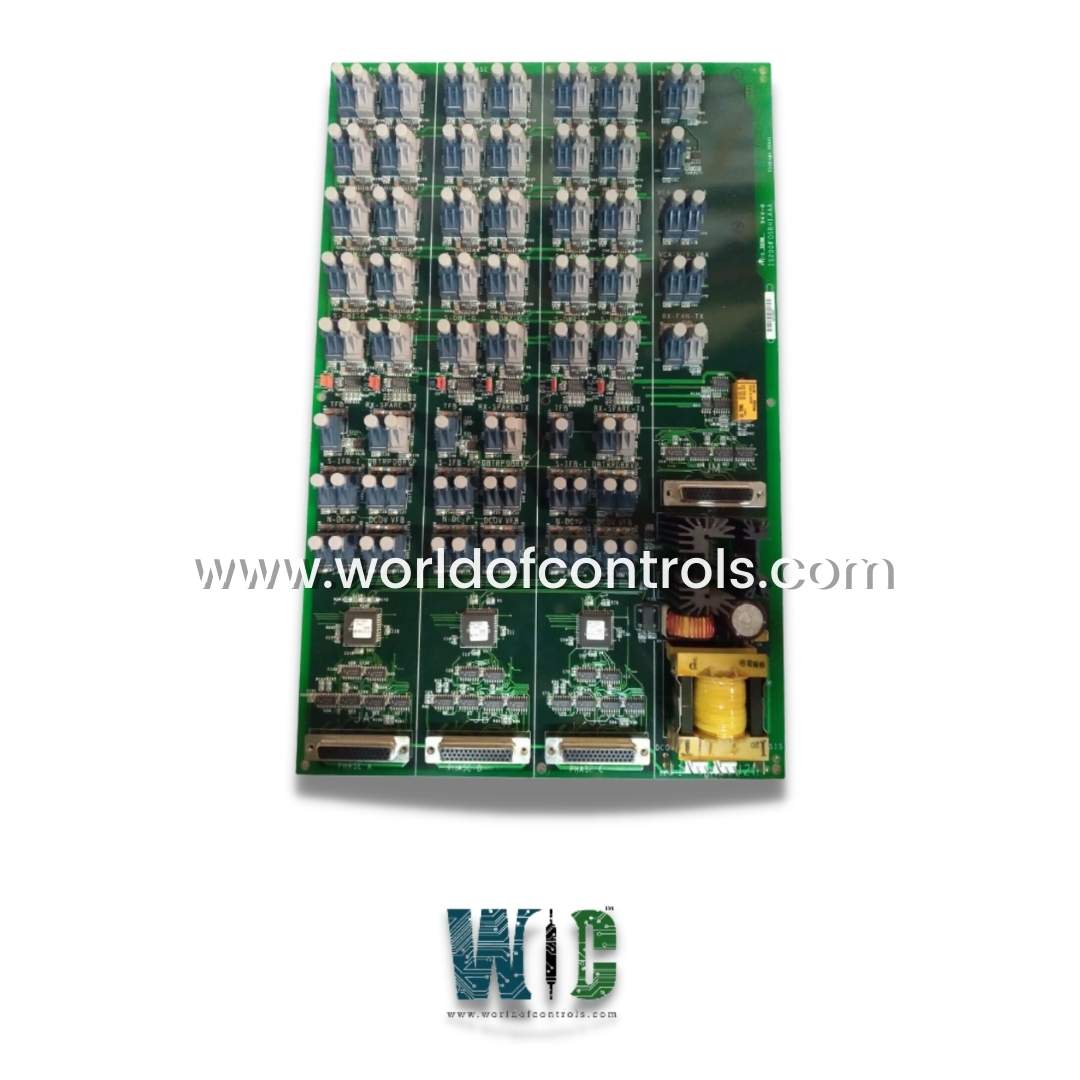

Part Number: IS200FOSBH1A

Manufacturer: General Electric

Series: Drive Control

Country of Manufacture: United States (USA)

Fiber-optic connectors: 102

Test points: 2

Plug connectors: 6

Function: Fiber-Optic Interface board

Functional Description

IS200FOSBH1A is a Fiber-Optic Interface board developed by GE. It is a part of the drive control series. When replacing or removing the board, use the manufacturer's recommended handling precautions. Your purchase is protected by a comprehensive warranty that covers our industrial hardware. Our stock comprises brand new surplus units, refurbished units, and unused items.

Features

- Distribution Array Board: The board acts as a distribution array board within the Innovation series drive. Its primary purpose is to facilitate the connection of signals from the BICH (Bridge Interface Control High Voltage) and BPIH (Bridge Power Interface High Voltage) boards to the power bridge devices. By serving as a distribution point, the board efficiently routes and manages the signals, ensuring proper communication and control between the various system components.

- Gate Driver Status Multiplexing: Multiplexes gate driver status signals from the BICH/BPIH boards on a per-phase basis. This functionality allows for efficient monitoring and control of the gate driver status across different phases of the power bridge. By multiplexing these signals, the board enables comprehensive signal processing, protective measures, gating operations, and feedback interface functions for the DSPX Digital Signal Processor Control Board.

- Fault Detection and Reporting: Equipped with fault detection capabilities. It can detect bridge faults and initiate soft-shutdown fault sequences as necessary. This feature ensures that any faults or abnormalities in the power bridge operation are promptly detected and addressed, minimizing the risk of further damage or system instability. Additionally, the board can detect and report missing or incorrectly connected cables, providing valuable information for troubleshooting and maintenance purposes.

- Connectors and Test Points: Features a variety of connectors and test points to facilitate its installation, testing, and connectivity. It includes two stab-on connectors, two TP test points for easy access to diagnostic signals, and six board connectors for interfacing with other system components. Additionally, the board is equipped with 102 fiber-optic connectors, each paired with a light-emitting diode (LED) indicator, allowing for efficient optical signal transmission and monitoring.

- Design and Power Supply: Designed without fuses or other adjustable hardware components. This design choice simplifies the board's construction and enhances its reliability and robustness. The board receives power from the GDPA High-frequency Power Supply board, which supplies the necessary power for its operation. A transformer and a 5V power supply are included on the board to ensure proper power distribution and regulation.

- Its connectors, test points, and fiber-optic interfaces enable efficient connectivity and monitoring. With its reliable design and power supply, the board contributes to the overall performance and functionality of the Innovation series drive, ensuring efficient power bridge operation and system control.

Product Attributes

- Fiber Optic Connectivity: Features fiber optic connectivity, allowing for high-speed and reliable communication between devices within industrial control systems. Fiber optic technology offers numerous advantages, including immunity to electromagnetic interference, long-distance transmission capabilities, and high bandwidth for efficient data transfer. With fiber optic connectivity, the component ensures seamless and secure communication between components, enhancing the overall performance and reliability of the system.

- Rugged Design: Designed to withstand harsh industrial environments. It features a rugged construction that can endure demanding conditions, including temperature variations, humidity, vibrations, and potential physical impacts. The board incorporates robust electrical and mechanical components, ensuring its durability and longevity even in challenging operational settings. The rugged design contributes to the system's overall reliability and resilience.

- Advanced Diagnostics: Equipped with advanced diagnostic capabilities. These diagnostics enable operators and maintenance personnel to quickly identify and troubleshoot any issues that may arise during operation. The board provides detailed information and feedback about its own status, as well as the connected components and systems. By leveraging advanced diagnostics, operators can efficiently diagnose and resolve problems, minimizing downtime and optimizing system performance.

- High-Speed Data Transfer: Supports high-speed data transfer, facilitating fast and reliable communication between devices within industrial control systems. With high-speed data transfer capabilities, the board enables efficient exchange of information, commands, and feedback between different components of the system. This swift and reliable data transfer enhances the system's responsiveness, accuracy, and overall operational efficiency.

System Fault Detection

- The fault detection design inherent in the I/O packs brings valuable benefits to all Mark VIe systems. Each pack incorporates specialized fault detection methods aimed at verifying proper operation. This is achievable due to the robust local processing capability embedded within every input and output pack. Several instances of this approach include:

- Analog to digital (A/D) converters undergo continuous comparison against a reference standard during each conversion cycle. If the resulting calibrated input signal falls beyond acceptable boundaries, the pack is flagged as having poor health.

- Analog output 4-20 mA signals utilize a small current-sense resistor situated on the output terminal board. This signal is read back via a distinct A/D converter and is cross-referenced with the instructed value. Should the discrepancy between the instructed and actual values exceed an acceptable threshold, the output signal is marked as being in an unfavorable health state.

- Discrete input opto-isolators are cyclically transitioned to an active state and subsequently deactivated. This process occurs independently of the actual input signal and is executed rapidly to avoid interference with the time capture of the sequence of events (SOE). If any signal path remains stuck and fails to respond to the test command, the signal is deemed to be in an unsatisfactory health condition.

World of Controls can also supply unused and rebuilt FOSB backed up with a warranty. Our team of experts is available round the clock to support your GE needs. Our team at WOC is happy to assist you with any of your automation requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IS200FOSBH1A?

It is a Fiber-Optic Interface board developed by GE

What is the FOSBH Fiber Optic Interface Board used for?

It is used within the Innovation series drive as a distribution array board. It is designed to interface signals from the BICH and BPIH boards and bridge power devices.

What functions does the component provide?

It provides signal processing, protective, gating, and feedback interface functions, as well as the ability to detect and signal missing or improperly connected cables, and initiate soft-shutdown fault sequences when necessary.

Why is fault detection crucial in complex control systems?

Fault detection is essential as it helps identify anomalies or failures within the system promptly. This enables timely interventions and prevents potential damage or disruptions.

What is the significance of locating fault detection close to the output of a system?

Positioning fault detection as close to the output as possible enhances reliability. It minimizes the risk of undetected issues and ensures that problems are spotted before they impact the final output.

How does the Mark VIe control system address fault detection challenges?

The Mark VIe control system employs triple redundant controllers and I/O modules to bolster fault detection capabilities. This involves using three controllers and comparing their outputs to identify any discrepancies, ensuring a high level of reliability.

What is the advantage of employing triple redundancy in controllers and I/O modules?

Triple redundancy involves using three instances of controllers and I/O modules. By comparing the outputs of these instances, the system achieves robust fault detection and even masking of faults, contributing to enhanced system reliability.

What are the physical attributes of the board?

It has two stab-on connectors, two TP test points, and six board (plug) connectors, and is built with 102 fiber-optic connectors that each pair with a light emitting diode indicator. The component does not have fuses or any other type of adjustable hardware.