World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

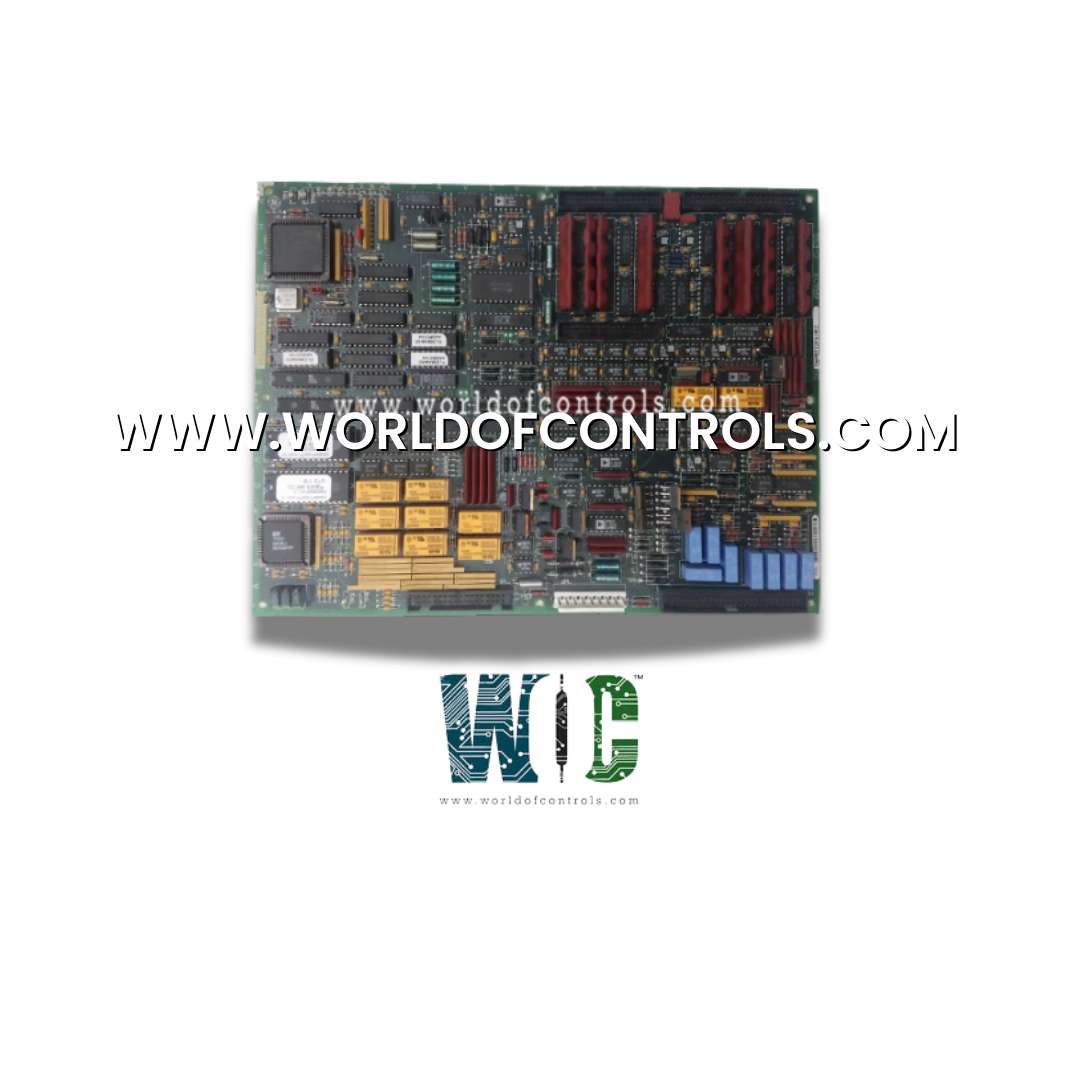

DS200TCQFG1ACB - TC2000 Analog I/O Extension Board is available in stock which ships the same day.

DS200TCQFG1ACB - TC2000 Analog I/O Extension Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCQFG1ACB - TC2000 Analog I/O Extension Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200TCQFG1ACB

Manufacturer: General Electric

Series: Mark V

Product Type: TC2000 Analog I/O Extension Board

Number of Analog Inputs: 8

Input Signal Range: 0–10V

Input Resolution: 12-bit

Input Impedance: >100 k Ohms

Number of Analog Outputs: 4

Power Supply Voltage: 24V DC ±10%

Operating Temperature: -20°C to +60°C

Mounting Type: DIN rail

Output Signal Range: 0–10V, 4–20mA

Operating temperature: -30 to 65°C

Size: 30 cm high x 18 cm

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCQFG1ACB is a TC2000 Analog I/O Extension Board manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. This board allows the main controller to interface with additional analog sensors and actuators, enabling precise monitoring and control of process variables such as temperature, pressure, flow, and level. The board typically supports multiple analog channels, offering flexible voltage and current signal ranges like 0–10V or 4–20mA. Engineered with high-resolution converters and signal isolation features, the TC2000 Analog I/O Extension Board enhances the performance and scalability of critical control systems.

INSTALLATION:

The board is typically connected to the main TC2000 controller via a backplane connector or dedicated ribbon cable, ensuring reliable data and power transfer. Before installation, power to the system should be turned off to avoid any electrical hazards. Once mounted, input and output wiring are connected to the terminal blocks—these may include shielded cables for analog signals to minimize interference. Proper labeling and adherence to wiring schematics is essential to maintain system integrity and ensure accurate data acquisition and output functionality.

OPERATION:

The controller communicates with the board to read analog input signals from field sensors and to send analog output signals to devices like control valves or actuators. The high-resolution analog-to-digital and digital-to-analog converters ensure that signal accuracy is preserved, which is critical in tightly controlled environments. The system software, often programmable via HMI or SCADA, allows operators to configure input scaling, set output ranges, and monitor real-time performance. Diagnostic features may also be available to detect wiring issues, signal loss, or calibration errors, ensuring robust and reliable system operation over time.

WOC has the largest GE Speedtronic Gas Turbine Control System Replacement Parts stock. We can also supply unused and rebuilt backup with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is the function of the TC2000 Analog I/O Extension Board in a control system?

The TC2000 Analog I/O Extension Board serves as a modular peripheral that expands the analog signal handling capabilities of the TC2000 controller. It allows for the acquisition and output of analog signals such as voltages or currents, making it suitable for integration with field devices like temperature sensors, pressure transducers, flow meters, and actuators.

What analog signal ranges does the board support?

The TC2000 Analog I/O Extension Board is designed to support standard industrial analog signal ranges, including 0–10V, ±10V, 0–5V for voltage inputs, and 4–20mA for current inputs and outputs. This compatibility ensures seamless integration with a wide range of field instruments and devices commonly used in process control and automation systems.

Are diagnostic and fault monitoring features included?

Most TC2000 Analog I/O Extension Boards are equipped with built-in diagnostics, including channel-specific fault detection (such as open circuit or over-range), status LEDs for monitoring channel activity, and onboard self-test routines. These diagnostics help ensure system integrity and provide early warning of signal or hardware issues.