World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

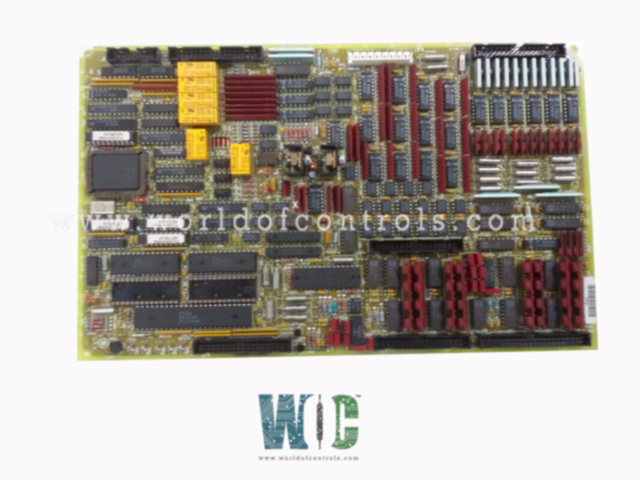

DS200TCQAG1ABA - Analog IO Board is available in stock which ships the same day.

DS200TCQAG1ABA - Analog IO Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCQAG1ABA - Analog IO Board, contact us and we will get back to you within 24 hours.

Part Number: DS200TCQAG1ABA

Manufacturer: General Electric

Series: Mark V

Temperature: -30 to 65oC

Availability: In Stock

Product type: Analog IO Board

Country of Manufacture: United States (USA)

DS200TCQAG1ABA is an Analog IO Board developed by GE. It is a part of the Mark V control system. The Analog IO Board plays a role in the Mark VIe system by scaling and conditioning a variety of analog signals received from terminal boards mounted on the I/O cores R1, R2, and R3. These signals are essential for monitoring and controlling various aspects of turbine operations.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200TCQAG1ABA?

It is an Analog IO Board developed by GE.

How does the board integrate with other components in the system?

Signals processed are written to the STCA board via the 3PL connector. Additionally, generator and line signals are exchanged with the TCQC board via the JE connector. These integrations ensure effective communication and coordination within the turbine control system.

What is the role of the board in handling 4-20 mA signals?

It scales and conditions 4-20 mA input signals, such as fuel flow pressure and compressor stall-detect signals. This ensures these signals are accurately represented and compatible with the system's operational requirements.

Why is signal scaling and conditioning important on the board?

Signal scaling and conditioning ensure that analog signals are accurate and suitable for further processing within the control system. This accuracy is critical for monitoring turbine operations, maintaining efficiency, and enabling responsive control actions based on real-time data inputs.