World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

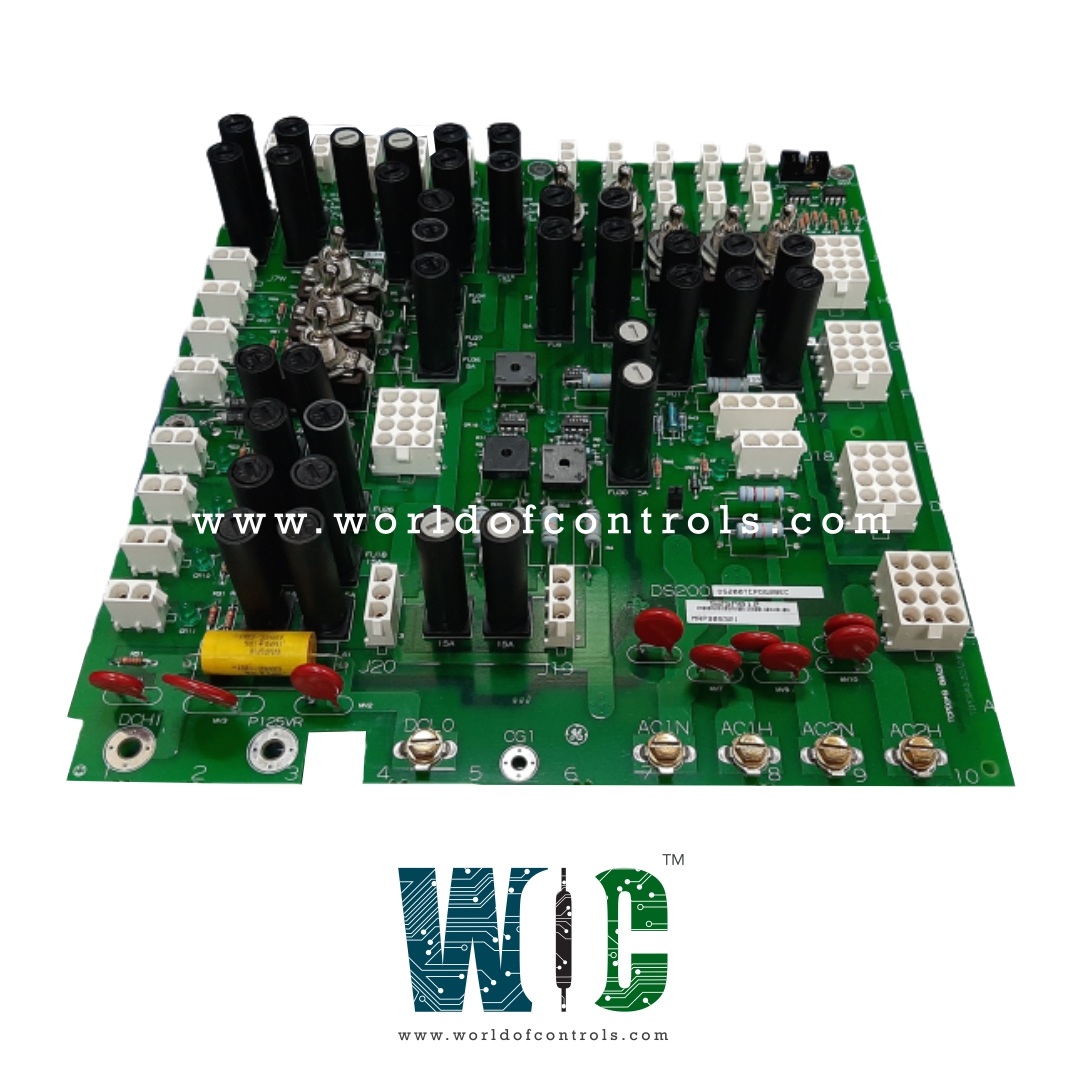

DS200TCPDG3BE - Power Distribution Module is available in stock which ships the same day.

DS200TCPDG3BE - Power Distribution Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCPDG3BE - Power Distribution Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200TCPDG3BE

Manufacturer: General Electric

Series: Mark V LM

Product Type: Power Distribution Module

Number of channels: 24

Power supply voltage: 28 V dc

Voltage Range: 14 to 32 V dc

Mounting: DIN-rail mounting

Technology: Surface mount

Operating temperature: -30 to 65°C

Size: 30 cm high x 18 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCPDG3BE is a Power Distribution Module manufactured and designed by General Electric as part of the Mark V LM Series used in GE Speedtronic Gas Turbine Control Systems. The Power Distribution Module (TCPD), located in the

TCPD CONNECTORS:

TCPD POWER:

External 115/230 V ac power and 125 V dc power is brought in via TB1 mounted on the

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What are the key components of a PDM used in turbine control systems?

Typical components of a PDM in turbine control systems include relays, circuit breakers, fuses, solid-state switches, and communication interfaces. These components work together to regulate power flow, protect electrical circuits, and enable communication with other control and monitoring systems.

How does a PDM enhance the functionality of turbine control systems?

PDMs streamline the wiring layout and improve system reliability by centralizing power distribution. They allow for easier troubleshooting and maintenance by providing diagnostic capabilities and fault isolation features. Additionally, PDMs can integrate with the turbine's control network, enabling remote monitoring and control.

What are the specific safety features incorporated into PDMs for turbine control applications?

PDMs designed for turbine control applications often include features such as overcurrent protection, short-circuit protection, ground fault detection, and temperature monitoring. These safety features help prevent electrical failures and mitigate risks associated with turbine operation.