World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

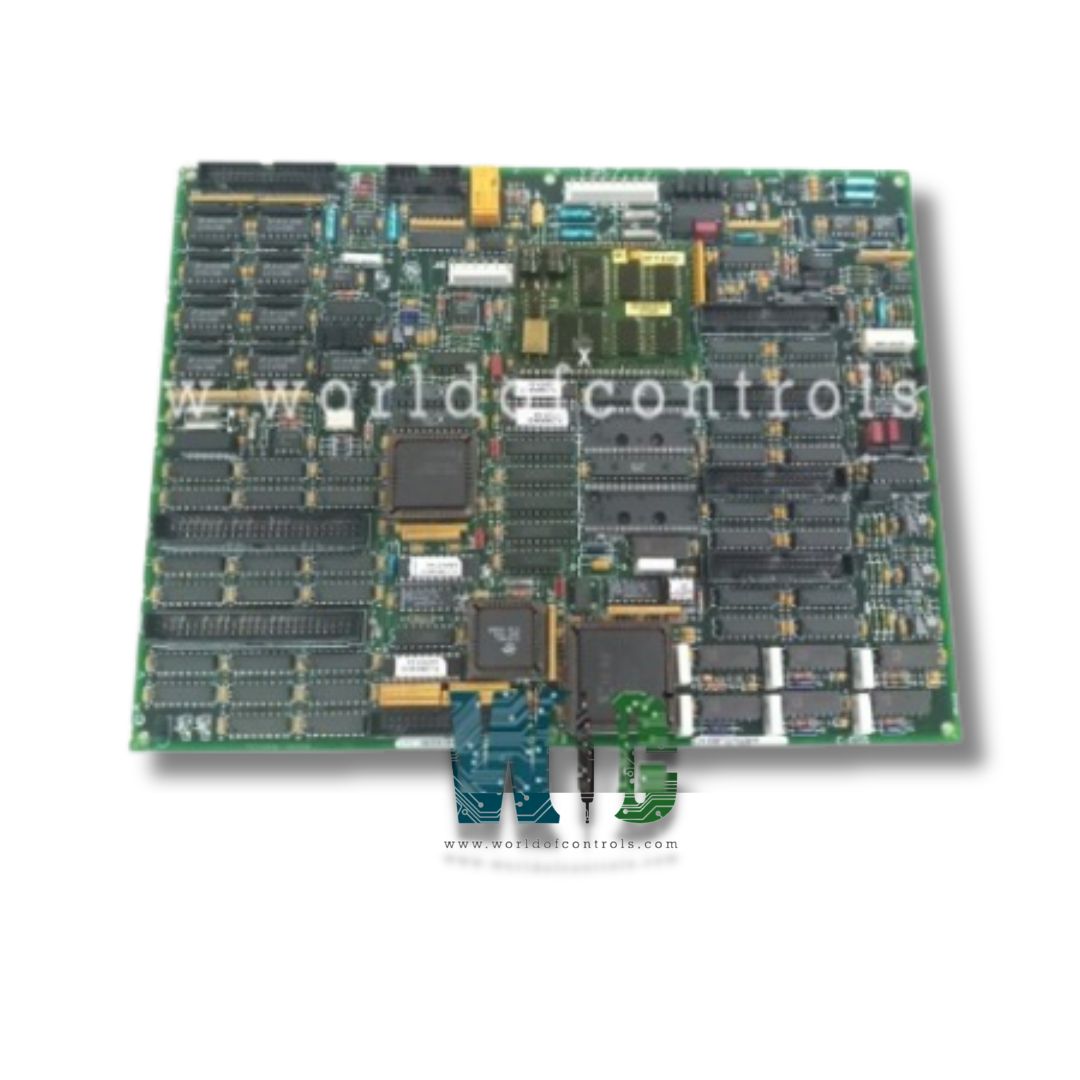

DS200TCCAG2BAA - Common Analog I/O Board is available in stock which ships the same day.

DS200TCCAG2BAA - Common Analog I/O Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCCAG2BAA - Common Analog I/O Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200TCCAG2BAA

Manufacturer: General Electric

Series: Mark V

Board Type: Common Analog I/O Board

Function: Data transmission, communication, diagnostics

Processor: 32-bit microprocessor

Power Consumption: 10-15 Watts

Mounting Location: R5 Core, VME Backplane Slot

Input Signal Types: 4-20 mA inputs

Output Signal Types: 4-20 mA

Thermocouple Support: Types J, K, T

Data Bus: VMEbus A24/A16

Operating Voltage: +5V DC

Board Dimensions: 6U VME

Size: 8.25 cm high x 4.18 cm

Repair: 3-7 Days

Availability: In Stock

Weight: 2.5 Kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCCAG2BAA is a Common Analog I/O Board manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. The Common Analog I/O Board (TCCA), positioned within the R5 core, plays a critical role in signal acquisition and conditioning within the turbine control system. It interfaces with multiple terminal boards, namely the CTBA, TBQA, and TBCA, which are also located in the R5 core. These terminal boards provide a variety of analog signal inputs, including 4-20 mA analog signals for process control, RTD (Resistance Temperature Detector) inputs for temperature measurement, thermocouple inputs, as well as shaft voltage and shaft current signals essential for monitoring generator performance. The TCCA board ensures that these incoming signals are accurately scaled, filtered, and conditioned before they are used by the control system for monitoring and decision-making.

Once conditioned, these analog signals are transmitted to the STCA (Simplex Trip Core Analog) board through the 3PL connector, facilitating seamless communication between analog input modules and digital processing boards. This transmission enables the turbine control system to accurately interpret real-time operating conditions and make precise adjustments to maintain optimal turbine performance and safety. The TCCA board, therefore, serves as a vital interface that bridges raw field data with the intelligent processing units of the control system.

INSTALLATION:

The TCCA board is installed within the R5 core of the turbine control system, typically mounted in a VME (Versa Module Europa) backplane slot designated for analog signal processing. Before installation, ensure that all power sources to the R5 core are properly shut down to prevent any electrical hazard or damage to the board. Carefully align the TCCA board with the VME slot rails and insert it gently but firmly into place until the edge connectors are fully seated. Secure the board using the mounting screws or latches provided to avoid vibration-related disconnections during operation.

Once installed, the TCCA board is connected to the CTBA, TBQA, and TBCA terminal boards via pre-configured wiring harnesses. These connections must be verified to ensure the correct routing of analog signals. The 3PL ribbon cable should also be properly connected from the TCCA to the STCA board to enable communication and data transfer. After installation and wiring, restore power and perform a system initialization or diagnostic check to verify that the TCCA board is functioning correctly and receiving/transmitting the appropriate analog signals without error.

OPERATION:

The TCCA board continuously receives analog signals from the CTBA, TBQA, and TBCA terminal boards, which are located in the R5 core. These signals include 4-20 mA current loops (used for process variables such as pressure or flow), RTD and thermocouple inputs for temperature monitoring, and shaft voltage and shaft current signals for generator diagnostics. The board's onboard circuitry is responsible for signal scaling, linearization, and isolation to ensure accurate and noise-free data suitable for processing.

Once the signals are conditioned, they are transmitted through the 3PL connector to the STCA (Simplex Trip Core Analog) board. The STCA processes this information further for use in control algorithms, protective functions, and operator displays. The TCCA plays a crucial role in maintaining system reliability by delivering precise analog measurements in real time, which are essential for efficient turbine operation, fault detection, and overall plant performance monitoring. The board also supports continuous diagnostics and error reporting, helping to identify issues such as signal loss, wiring faults, or sensor failures.

TCCA CONFIGURATION

The TCCA (Common Analog I/O) board is configured through both hardware jumpers and software settings, allowing for flexibility in adapting the board to various signal types and system requirements.

HARDWARE CONFIGURATION:

The TCCA board includes three key hardware jumpers: J1, JP2, and JP3, each serving a specific purpose in the board's configuration and testing.

SOFTWARE CONFIGURATION:

In addition to hardware settings, the TCCA board is configured through the I/O Configuration Editor available on the HMI (Human-Machine Interface). This software-based tool allows engineers and technicians to define the input and output signal parameters that the board will process. The following configurations are typically set in the editor:

WOC offers the largest inventory of replacement parts for GE Speedtronic Gas Turbine Control Systems. We provide both unused and rebuilt boards backed by warranty as well as expert repair services for damaged units. Our team of professionals is available 24/7 to support all your OEM and automation requirements. For pricing and availability on components or repair services, please reach out to us via phone or email.

What is the primary function of the TCCA board?

The TCCA (Common Analog I/O) board is responsible for receiving, conditioning, and scaling various analog input and output signals from terminal boards such as CTBA, TBQA, and TBCA mounted within the R5 core of the turbine control system. It processes signals like 4-20 mA current loops, resistance temperature detector (RTD) inputs, thermocouple signals, and shaft voltage/current inputs.

What is the purpose of the 3PL connector on the TCCA?

The 3PL connector is a multi-pin ribbon cable interface that connects the TCCA board to the STCA (Simplex Trip Core Analog) board. It acts as the primary data pathway for transmitting conditioned analog signals. This connection ensures that critical analog inputs reach the STCA for further processing, integration into control logic, or logging for diagnostics.

Can signal scaling be adjusted without removing the board?

Yes, signal scaling for inputs and outputs (such as 4-20 mA loops or thermocouple ranges) can be adjusted through the I/O Configuration Editor on the HMI. There is no need to physically remove the board to make these changes.