World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200TCCAF1ADD - Software PROM Set is available in stock which ships the same day.

DS200TCCAF1ADD - Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCCAF1ADD - Software PROM Set, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

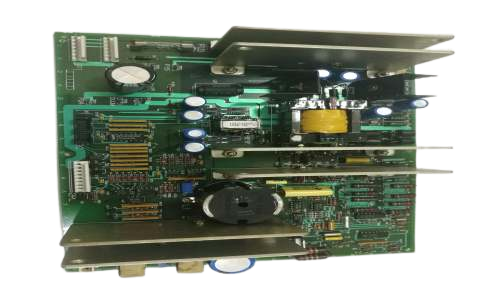

Part Number: DS200TCCAF1ADD

Manufacturer: General Electric

Series: Mark V

Product Type: Software PROM Set

Number of relay channels: 12

Power supply voltage: 28 V dc

Operating temperature: -30 to +65°C

Size: 15.9 cm high x 17.8 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCCAF1ADD is a Software PROM Set manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Control Systems. The Mark V system is designed to boost unit reliability by employing three redundant control processors. This innovative triple modular redundant (TMR) setup ensures the safe operation, control, and protection of a unit even if one of its control processors fails. With this design, a single control processor can undergo maintenance and repair without necessitating a complete turbine shutdown.

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is the role of a Software PROM Set in a Gas Turbine Control System?

A Software PROM Set in a Gas Turbine Control System contains the essential software, configuration settings, and instructions necessary to program PROM chips, enabling precise control and management of various functions within the gas turbine.

What does a Software PROM Set typically include in a Gas Turbine Control System?

It generally consists of firmware, specific control algorithms, safety protocols, operational parameters, and other data crucial for governing the functioning, performance, and safety measures of the gas turbine.

How is a Software PROM Set used in a Gas Turbine Control System?

The set is employed to program PROM chips, configuring them with the required control logic, safety parameters, and operational settings. These PROM chips, once programmed, are responsible for controlling and managing the gas turbine's various functions.