World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200GASCF1BGD - Software PROM Set is available in stock which ships the same day.

DS200GASCF1BGD - Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GASCF1BGD - Software PROM Set, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

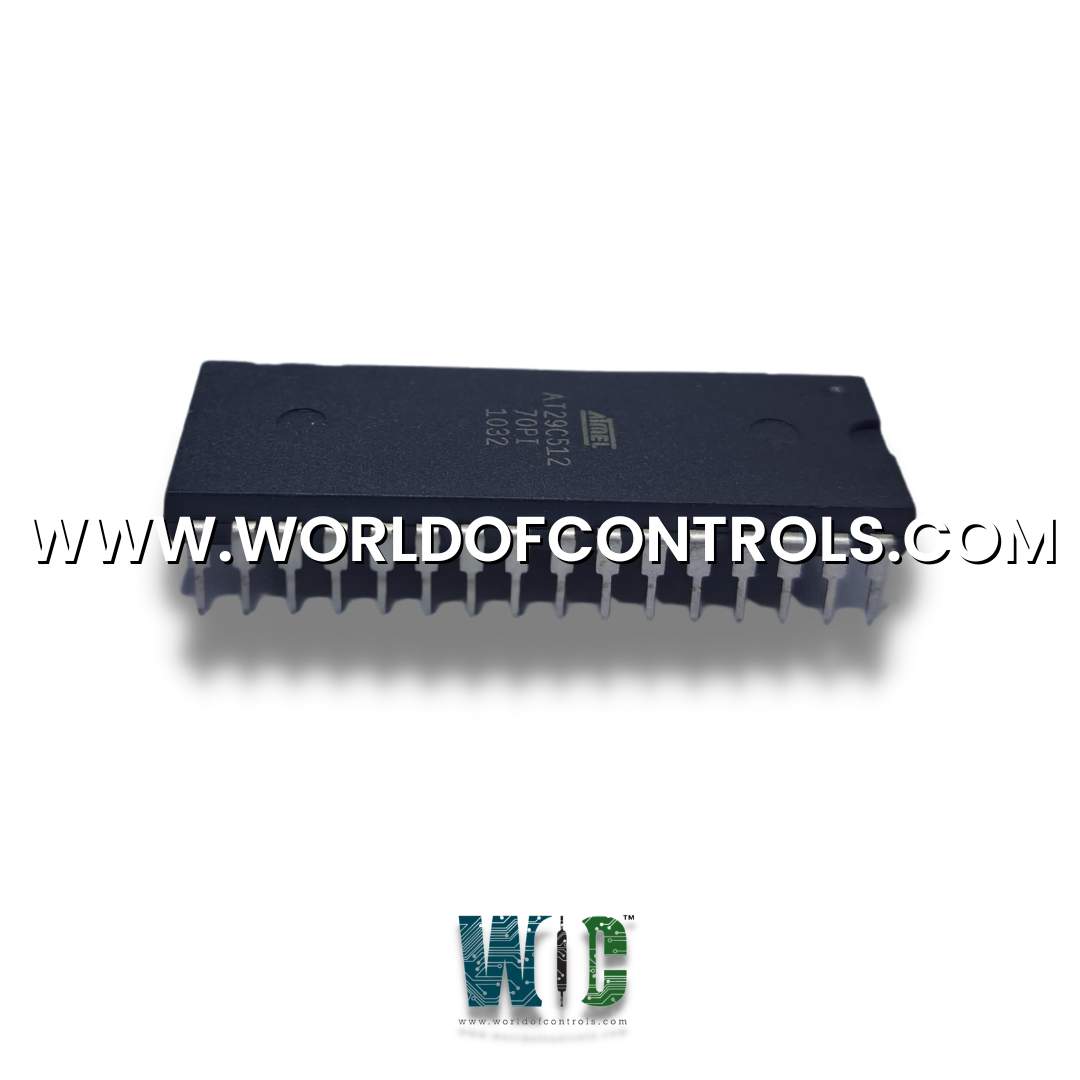

Part Number: DS200GASCF1BGD

Manufacturer: General Electric

Series: Mark V

Product Type: Software PROM Set

Number of relay channels: 12

Power supply voltage: 28 V dc

Operating temperature: -30 to +65�C

Size: 15.9 cm high x 17.8 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200GASCF1BGD is a Software PROM Set manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Control Systems. The Mark V system represents a significant advancement in turbine automation technology, resulting from decades of continuous improvement and experience spanning over 40 years. A notable aspect of this progress is the extensive use of electronic control technology, accounting for more than 80% of the system's evolution. This digital implementation of automation techniques builds upon a rich history of innovation and adaptability, encapsulating the collective knowledge gained from years of effectively managing turbines, adapting to changing requirements, and harnessing electronic control systems' capabilities.

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is a Data Exchange Communication Network (DENET)?

A Data Exchange Communication Network, or DENET, is a system or infrastructure that facilitates the exchange of data or information between different components or devices within a networked environment. It enables the seamless transfer of data for various purposes, including control, monitoring, and coordination.

What are the advantages of using I/O Communication Networks?

The benefits of I/O Communication Networks include real-time data exchange, reduced wiring and cabling, improved scalability, enhanced system flexibility, and the ability to monitor and control devices remotely.

What is Software-Implemented Fault Tolerance (SIFT)?

Software-Implemented Fault Tolerance, or SIFT, is a technology used to enhance the reliability and fault tolerance of software systems. It involves implementing mechanisms within software to detect and recover from faults or errors without relying solely on hardware redundancy.