SPECIFICATIONS

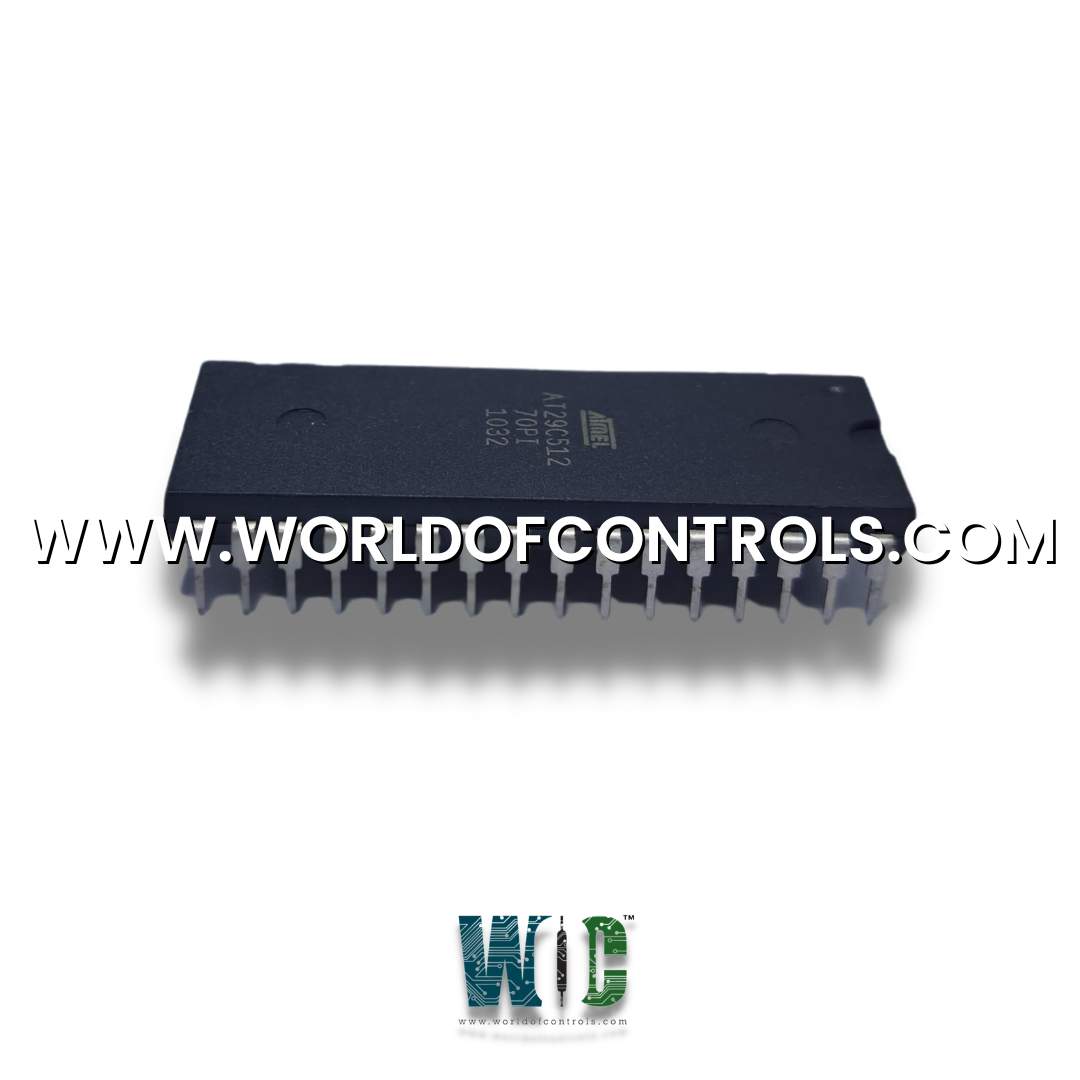

Part Number: DS200GASCF1BEL

Manufacturer: General Electric

Series: Mark V

Product type: Software PROM

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

DS200GASCF1BEL is a Software PROM designed and developed by GE. It is a part of the Mark V control system. EPROM is a advantageous memory storage due to its non-volatile nature, which allows it to preserve stored data even when not powered. This characteristic eliminates the need for continuous power supply to retain information, making it self-sufficient in maintaining its memory state without relying on external power sources or additional memory components.

Features

- The non-volatile attribute of EPROMs ensures that once programmed, the data remains intact over extended periods, even in the absence of an active power source. This feature makes EPROMs highly reliable and suitable for applications where data persistence is crucial, such as in embedded systems, firmware, or critical control settings.

- Moreover, the reprogrammable nature of EPROMs significantly enhances their utility. Unlike other types of memory that are programmed once and remain static, EPROMs offer the flexibility of erasing and reprogramming the data they store. This capability allows for the modification, updating, or correction of stored information as needed, making EPROMs versatile and adaptable to changing requirements or evolving software needs.

- The process of reprogramming an EPROM involves erasing the existing data by exposing it to strong ultraviolet (UV) light through a quartz window integrated into the chip package. Once erased, new data can be programmed into the EPROM using specialized programming equipment. This reusability feature distinguishes EPROMs from other non-reprogrammable memory types, providing a cost-effective and efficient means of managing data storage and updates in various technological applications.

Mark V Contact Inputs

- The Mark V system utilizes the 125 V dc bus derived from the internal power distribution core to supply an interrogation voltage to the contact inputs. This voltage is designed to be fuse-isolated and current-limited, ensuring safety and protection for the system. While the primary voltage is 125 V dc, other input voltages ranging from 24 V dc to 125 V dc can be utilized, although they might necessitate an external power source distinct from the Mark V system.

- For the convenience of handling field grounds, the terminal boards are equipped with jumpers that enable the isolation of interrogation voltage from the contact inputs in groups of eight. This feature facilitates the disconnection of specific groups of inputs from the interrogation voltage, providing flexibility in system configuration and troubleshooting.

- Each contact input within the Mark V system is optically isolated, ensuring electrical separation and preventing interference between different input channels. Additionally, these inputs are capable of receiving a precise time stamp within 1 millisecond of any status change. This time-stamping capability allows for accurate recording and tracking of events associated with the contact inputs. Notably, the Mark V printer is capable of logging each status change of a contact input, inclusive of its associated time stamp, particularly if that input is chosen for sequence of events (SOE) logging.

- To ensure the reliability and functionality of the contact inputs, diagnostic circuitry embedded within the system performs regular tests every 1 millisecond on the internal electronics of each input. In the event of a failure within the circuitry, an alarm is promptly initiated, alerting operators or maintenance personnel to the issue. This diagnostic capability adds an extra layer of system integrity by proactively monitoring the health of the contact inputs and swiftly flagging any potential faults or malfunctions.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200GASCF1BEL?

It is a GE Software PROM designed and developed by GE

What voltage does the Mark V system use for contact inputs?

The system utilizes a 125 V dc bus derived internally for contact inputs. External voltages ranging from 24 V dc to 125 V dc are also compatible, though they may require an external power source separate from the Mark V system.

How are field grounds managed within the system?

Terminal boards feature jumpers that enable the isolation of interrogation voltage from contact inputs in groups of eight. This allows specific input groups to be disconnected from the interrogation voltage, aiding system configuration and troubleshooting related to field grounds.

How are contact inputs protected from interference?

Contact inputs in the Mark V system are optically isolated, ensuring electrical separation between different input channels. Additionally, these inputs receive precise time stamps within 1 millisecond of any status change, enabling accurate event recording and tracking.